Semiconductor device

a semiconductor and device technology, applied in semiconductor devices, semiconductor/solid-state device details, electrical devices, etc., can solve the problems of corroding electrode posts or connection wirings, disconnection of connection wirings, and difficulty in ensuring sufficient adhesion between the side surface of each post electrode and the sealing resin, so as to prevent the intrusion of moisture, prevent the separation, and prevent the effect of corrosion or disconnection of the connection wiring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

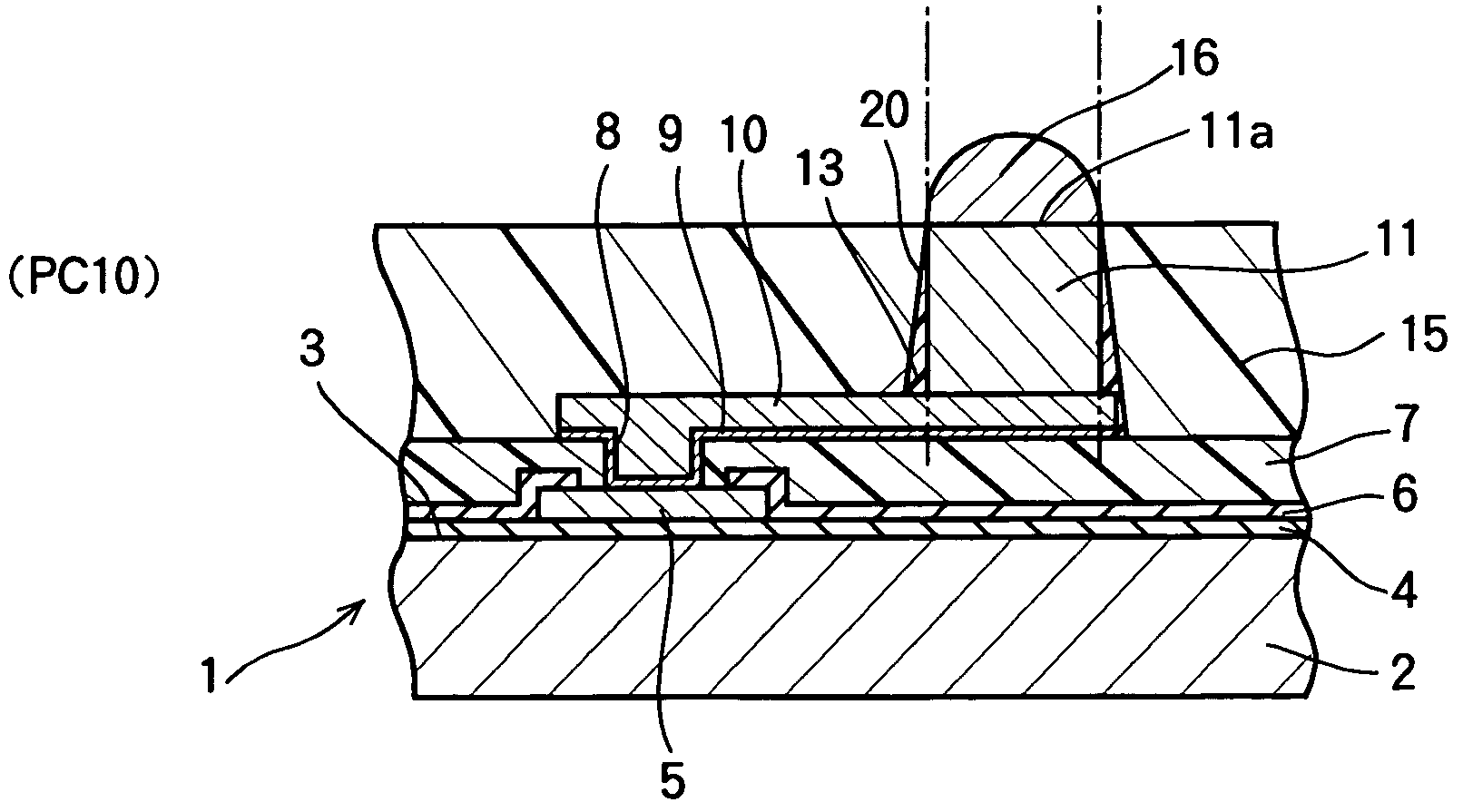

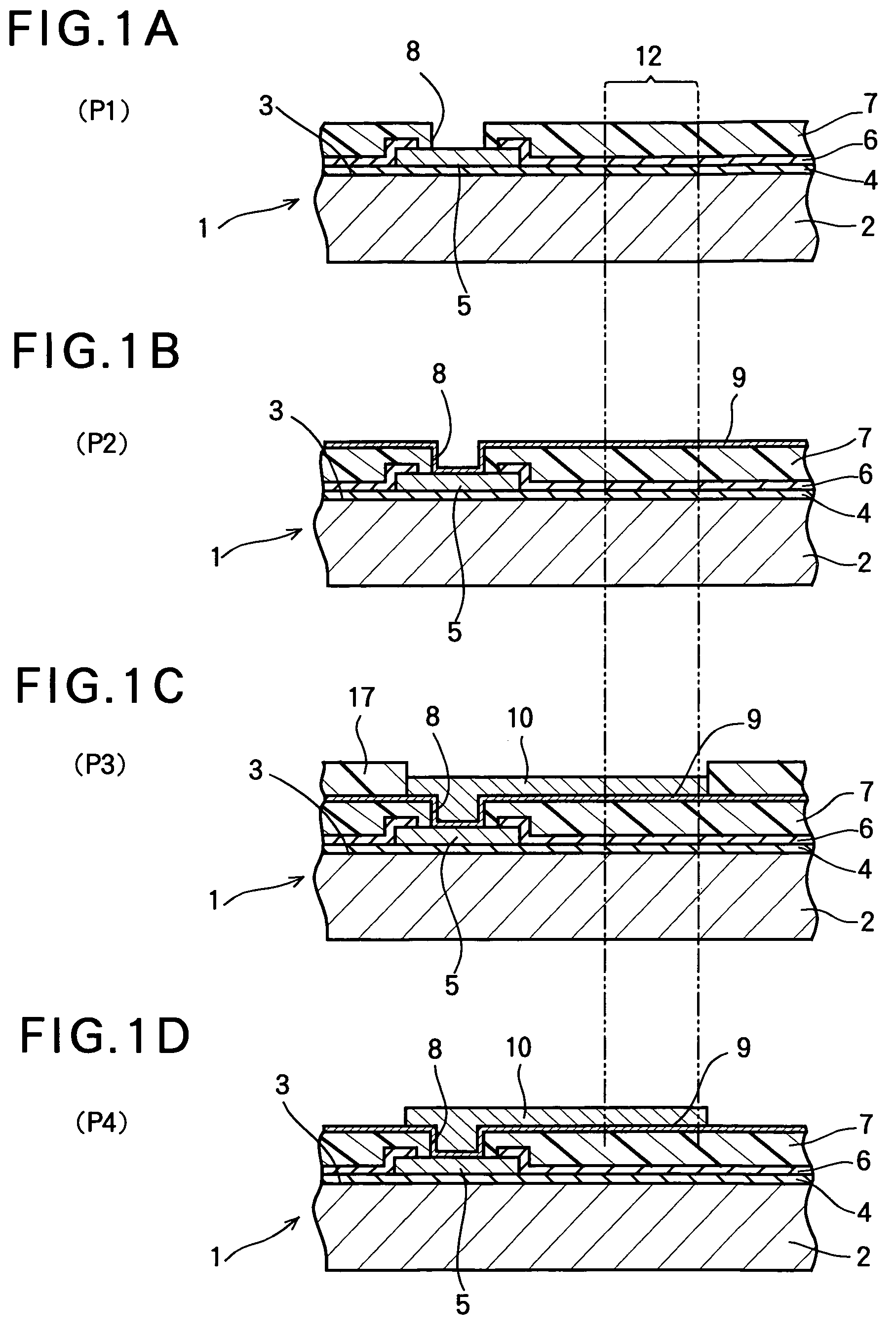

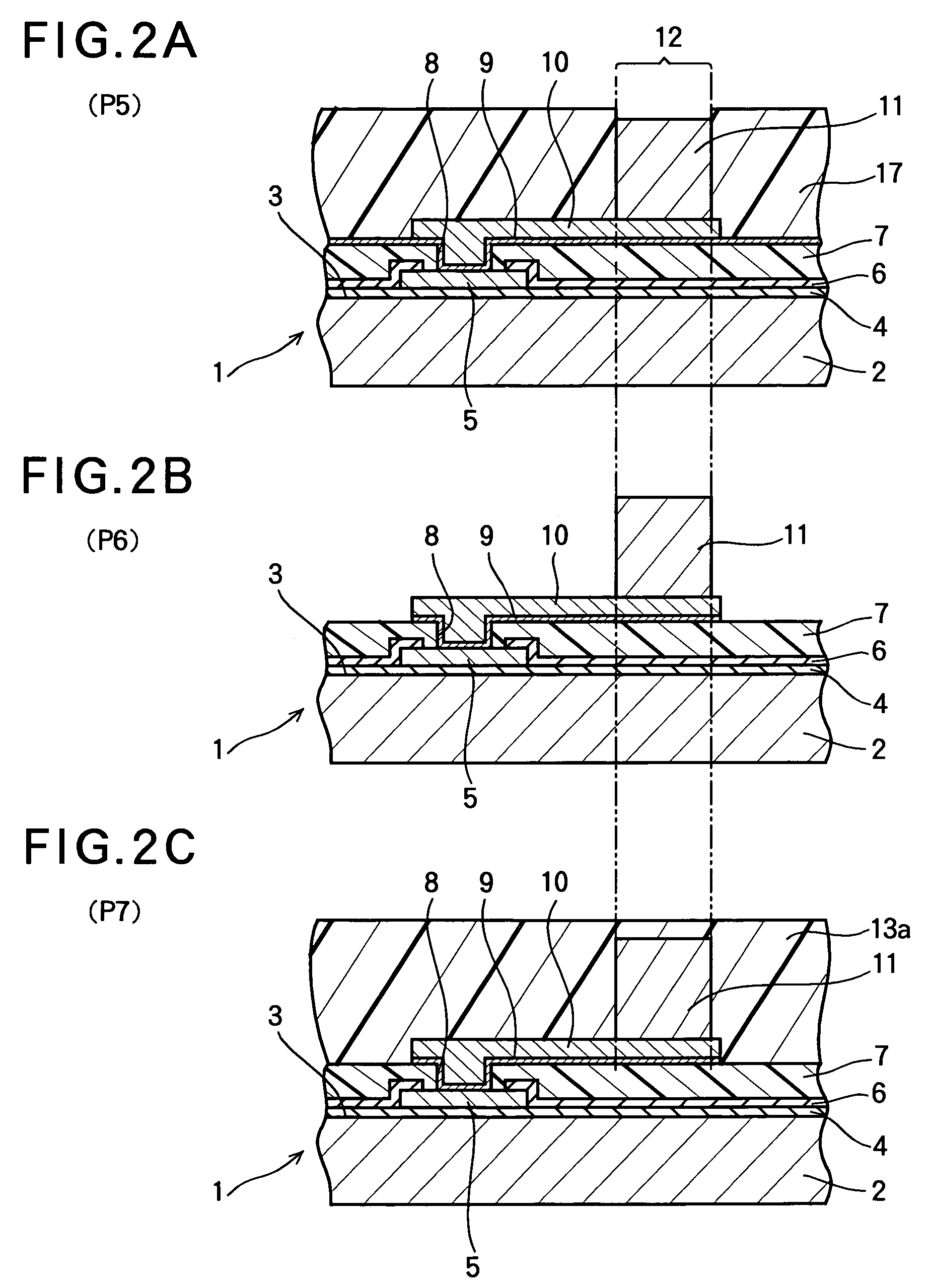

[0026]FIGS. 1A through 1D, FIGS. 2A through 2C and FIGS. 3A through 3C illustrate a manufacturing method of a semiconductor device according to the first embodiment of the present invention. FIGS. 1A through 3C are sectional views of a semiconductor device, and particularly show the vicinity of electrode pads and post electrodes connected to the electrode pads via connection wirings. In FIGS. 1A through 3C, only one electrode pad, one post electrode and one connection wiring are shown.

[0027]As shown in FIGS. 1A through 3C, a numeral 1 denotes a semiconductor wafer for manufacturing a plurality of CSP type semiconductor devices.

[0028]The semiconductor wafer 1 includes a semiconductor substrate 2 composed of silicon. A plurality of circuit elements are formed on the upper surface of the semiconductor substrate 2. The circuit elements are made of semiconductor elements connected to each other via connection wirings. The upper surface of the semiconductor substrate 2 on which the circui...

second embodiment

[0062]FIGS. 4A through 4D, FIGS. 5A through 5C and FIGS. 6A through 6C illustrate a manufacturing method of a semiconductor device according to the second embodiment of the present invention.

[0063]The components of the semiconductor device of the second embodiment that are the same as those of the first embodiment are assigned the same reference numerals, and duplicate explanation will be omitted.

[0064]In the second embodiment, the thickness T (shown in FIG. 6C) of the adhesion film 13 is preferably in the range from 5 μm to 40 μm, as was described in the first embodiment. This is because of the following reason (in addition to the reason described in the first embodiment). If the adhesion film 13 is thinner than 5 μm, there may be cases where the adhesion film 13 is not formed on a stepped portion around the connection wirings 10. In such a case, the difference in thermal expansion between the sealing layer 15 and the connection wirings 10 (during the heat treatment for forming the...

third embodiment

[0079]FIGS. 7A through 7E, FIGS. 8A through 8C, FIGS. 9A through 6C and FIG. 10 illustrate a manufacturing method of a semiconductor device according to the third embodiment of the present invention.

[0080]The components of the semiconductor device of the third embodiment that are the same as those of the first embodiment are assigned the same reference numerals, and duplicate explanation will be omitted.

[0081]In the third embodiment, the thickness T (shown in FIG. 10) of the adhesion film 13 is preferably in the range from 5 μm to 40 μm, as was described in the second embodiment.

[0082]In this embodiment, the thickness of the adhesion film 13 is 10 μm.

[0083]Hereinafter, the manufacturing method of the semiconductor device of the third embodiment will be described with reference to FIGS. 7A through 10.

[0084]The processes PB1 through PB4 shown in FIGS. 7A through 7D are the same as the processes P1 through P4 (FIGS. 1A through 1D) of the first embodiment, and therefore the explanation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com