Ultralow noise mode-locked laser and RF sinewave source

a laser and ultra-low noise technology, applied in the direction of wave amplification devices, laser details, electrical equipment, etc., can solve the problems of limited “quality factor” or q that are not overcome, the prior art oscillator also has problems, and the noise of the electronic oscillator is relatively high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044]Before explaining the disclosed embodiments of the present invention in detail it is to be understood that the invention is not limited in its application to the details of the particular arrangements shown since the invention is capable of other embodiments. Also, the terminology used herein is for the purpose of description and not of limitation.

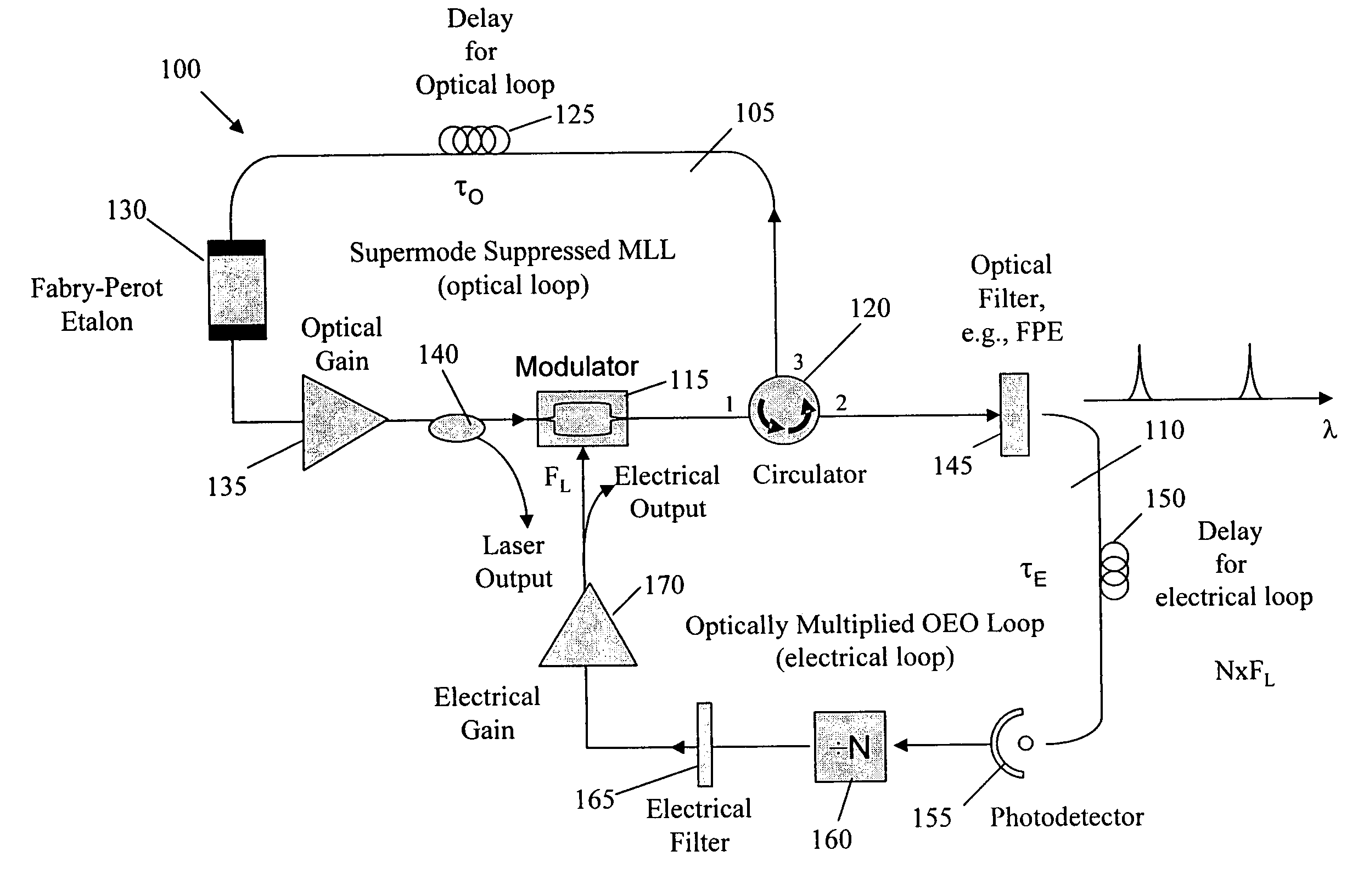

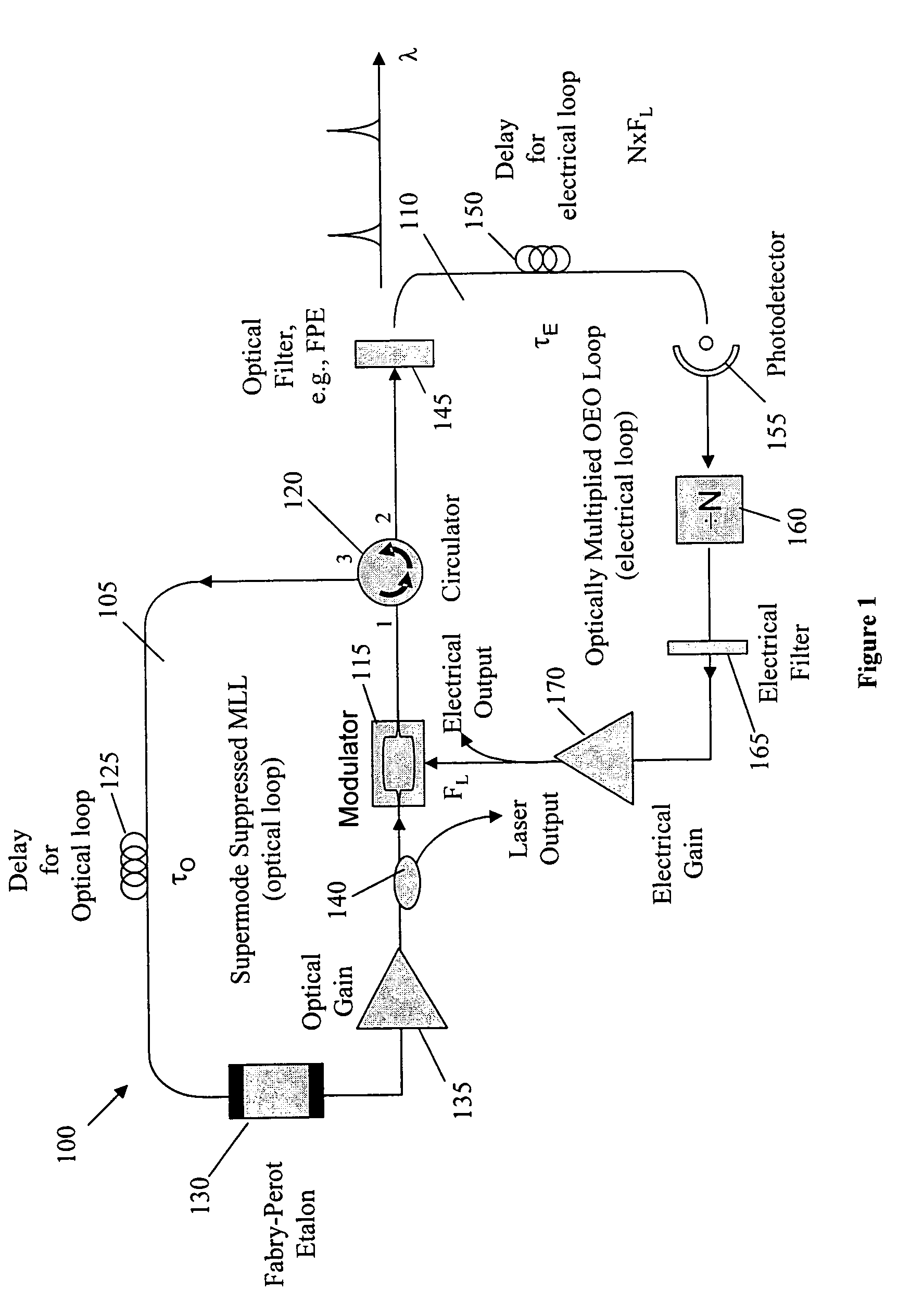

[0045]A preferred embodiment of the novel ultra-low noise mode-locked laser and RF sinewave source 100 is shown in FIG. 1. The optical loop 105 of the opto-electronic oscillator 100 forms an optical ring laser and is comprised of modulator 115, optical circulator 120, optical delay 125, Fabry-Perot Etalon 130, optical gain 135, and optical coupler 140. Optical gain 135 can be a device such as a semiconductor optical amplifier (SOA) or an erbium-doped fiber amplifier (EDFA). The modulator 115 can be a LiNbO3 Mach-Zehnder modulator or similar. Optical delay 125 can be a spool of fiber of approximately 100 meters in length. The electric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com