Poultry litter rejuvenating machine

a tractor-drawn machine and litter technology, applied in the field of tractor-drawn machines for rejuvenating poultry litter, can solve the problems of damage to the eyes and lungs of the later crop of young chicks placed on the used litter, detrimental to the life, and ammonia will seep out very slowly from the poultry floor, so as to save the time of rejuvenating litter, increase the life of poultry house litter, and reduce the amount of free dust and other materials floating in the air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

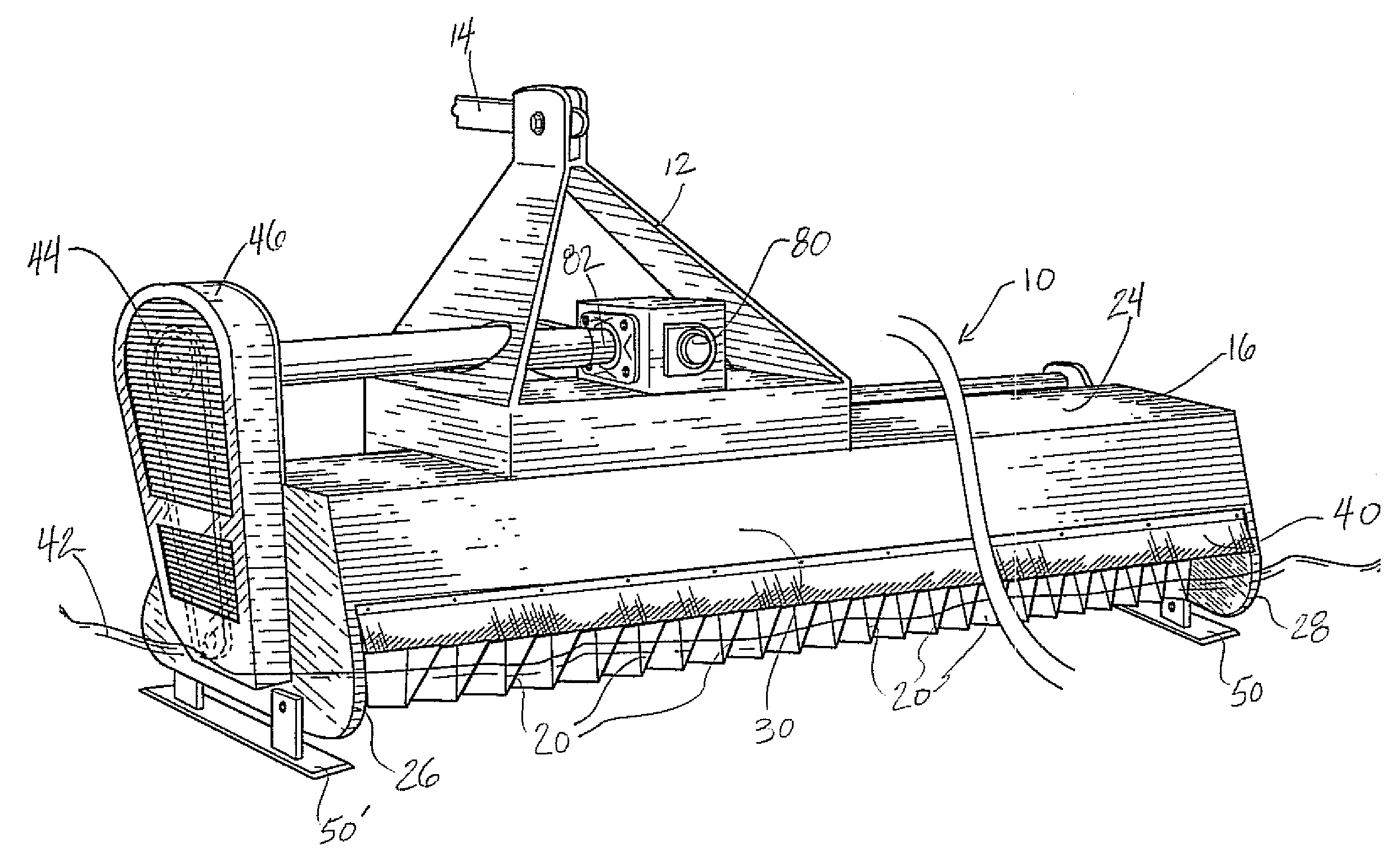

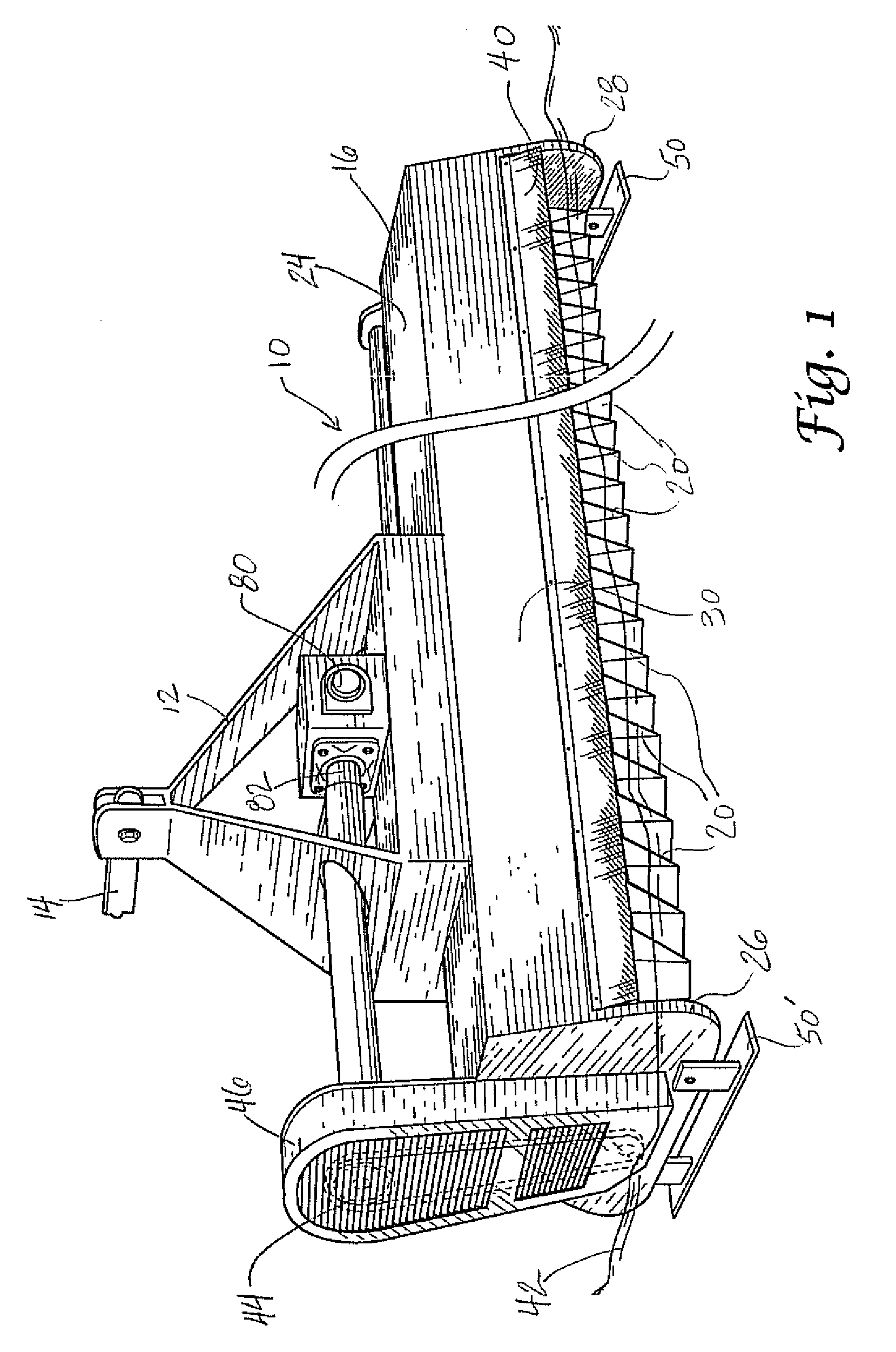

[0020]Referring to FIGS. 1 and 2 of the drawings, the litter rejuvenating machine of this invention, indicated generally at 10, is shown. The machine 10 projects laterally from one side of a tractor and includes an upper front frame 12 to which is rigidly secured a three-point hitch 14. The unit assembly of the machine 10 and hitch 14 is pivotally supported on a tractor for up and down movement in response to the actuation of an extensible link or hydraulic cylinder.

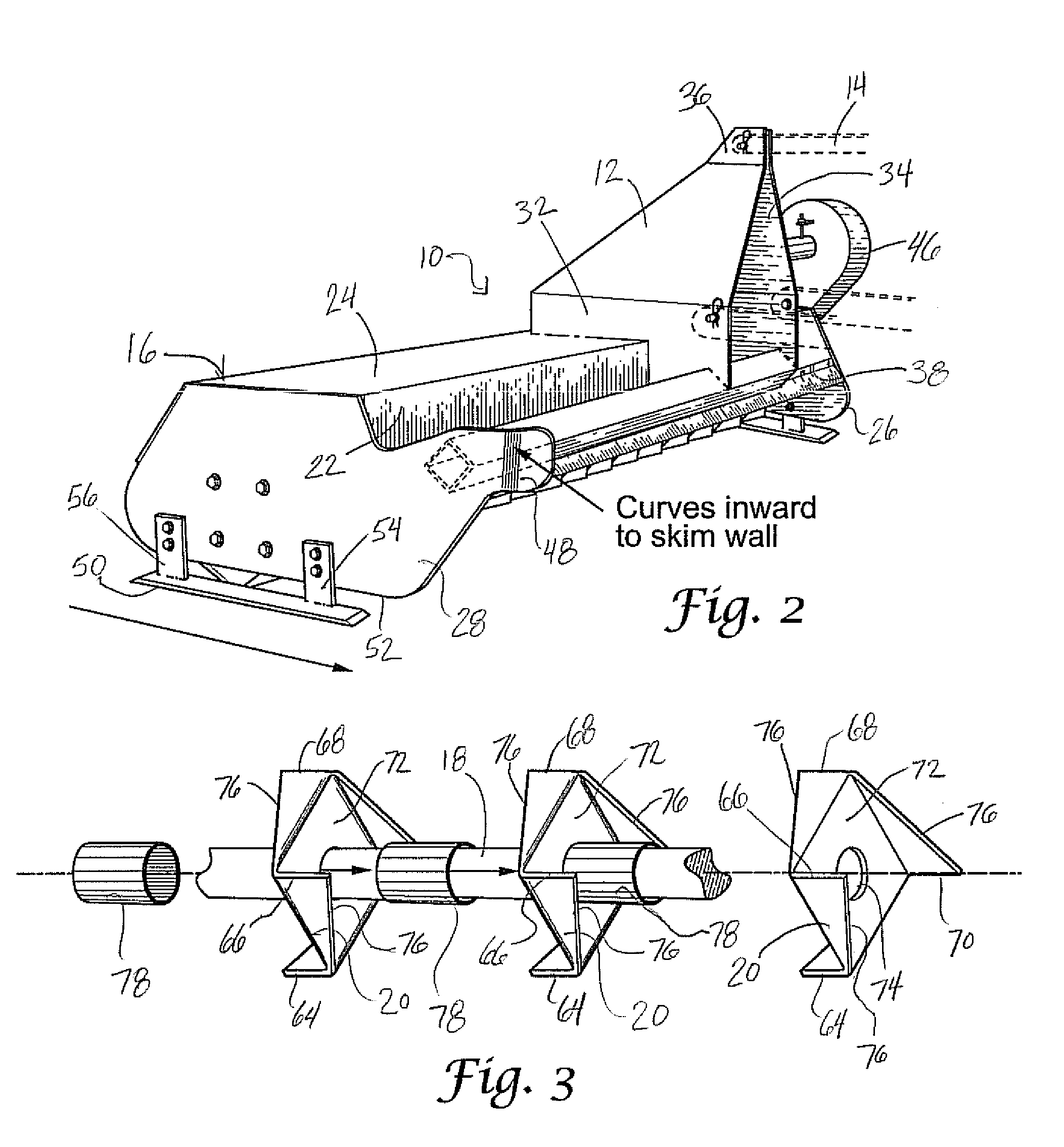

[0021]The machine 10 includes a deck 16, formed of a sheet metal material, covering a rotary shaft 18 and a number of peripheral blades 20. The deck 16 includes a front wall 22, a top wall 24, vertical end walls 26, 28, and a rear wall 30. The upper front frame 12 is secured to the top wall 24 and front wall 22 and includes side frame members 32, 34 and an upper bracket 36 formed at the top of the side frame members. A three-point hitch 14 can be attached to the lower portion of the side frame members 32, 34 and the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com