Pixel structure and fabricating method thereof

a technology of pixel structure and fabricating method, which is applied in the direction of non-linear optics, instruments, radio frequency controlled devices, etc., can solve the problems of waste of energy, and achieve the effect of superb display quality and higher aperture ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039]In the invention, a number of photomask processes is increased, so that a loss of an aperture ratio caused by disposition of a common electrode is prevented. A pixel structure having a high aperture ratio and superb display quality is thereby fabricated. Particularly, since the common line and a scan line are not formed by the same photomask process, occurrence of a short circuit between the common line and the scan line is prevented.

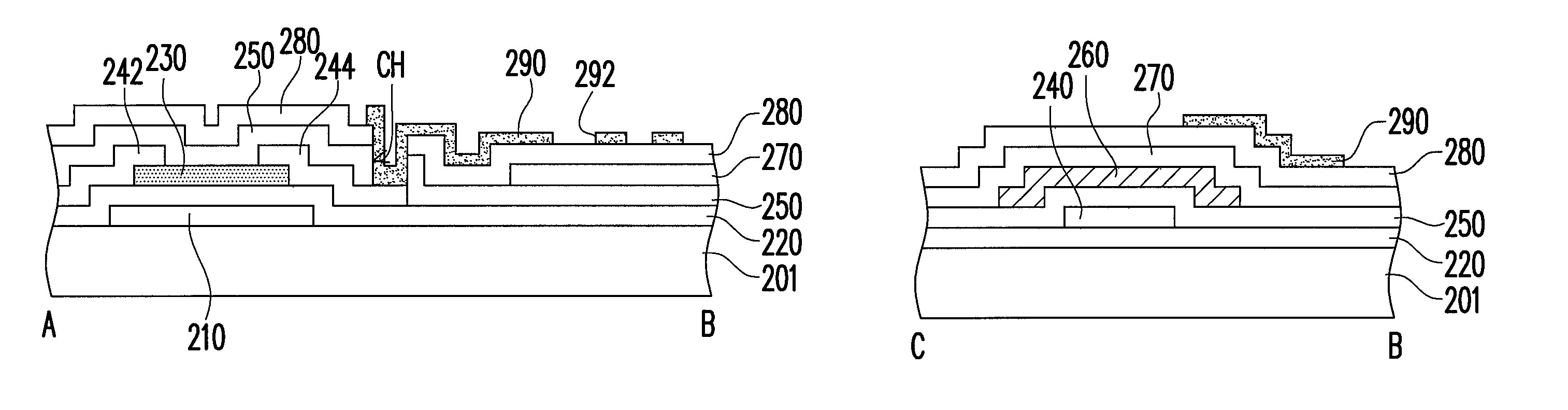

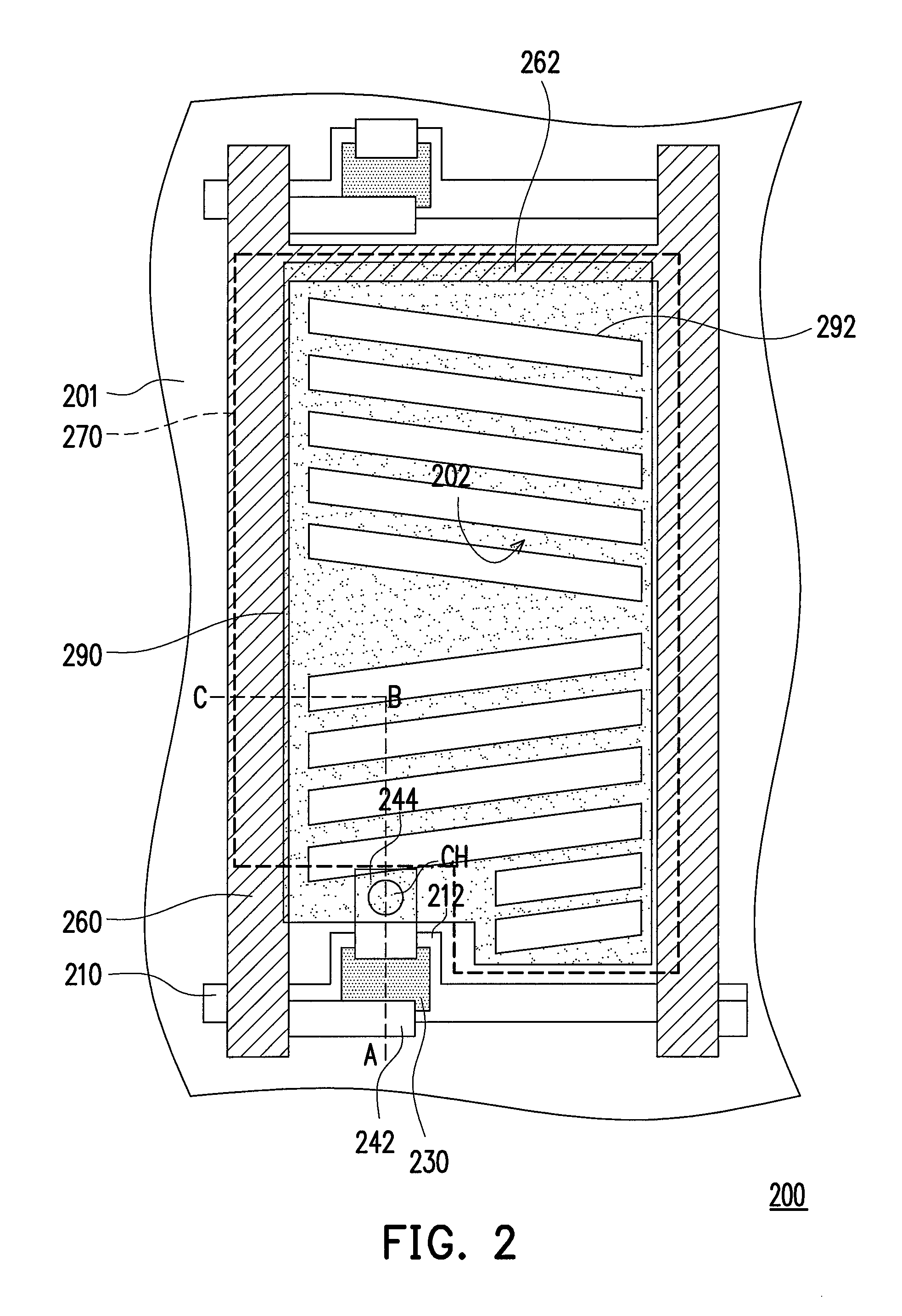

[0040]FIG. 2 is a schematic top view of a pixel structure according to an embodiment of the invention. FIGS. 3A and 3B are schematic cross-sectional views along lines A-B and B-C in FIG. 2 respectively.

[0041]Referring to all FIGS. 2, 3A, and 3B, a pixel structure 200 is disposed on a substrate 201. The substrate 201 includes a plurality of pixel areas 202 arranged in an array, and the pixel structure 200 is disposed in each of the pixel areas 202. In order to simplify the description, FIG. 2 only depicts one of the pixel areas 202. The pixel struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com