Non-destructive evaluation of functional fabrics

a functional fabric and non-destructive technology, applied in the field of non-destructive evaluation of functional fabrics, can solve the problems of affecting the quality of functional fabrics,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

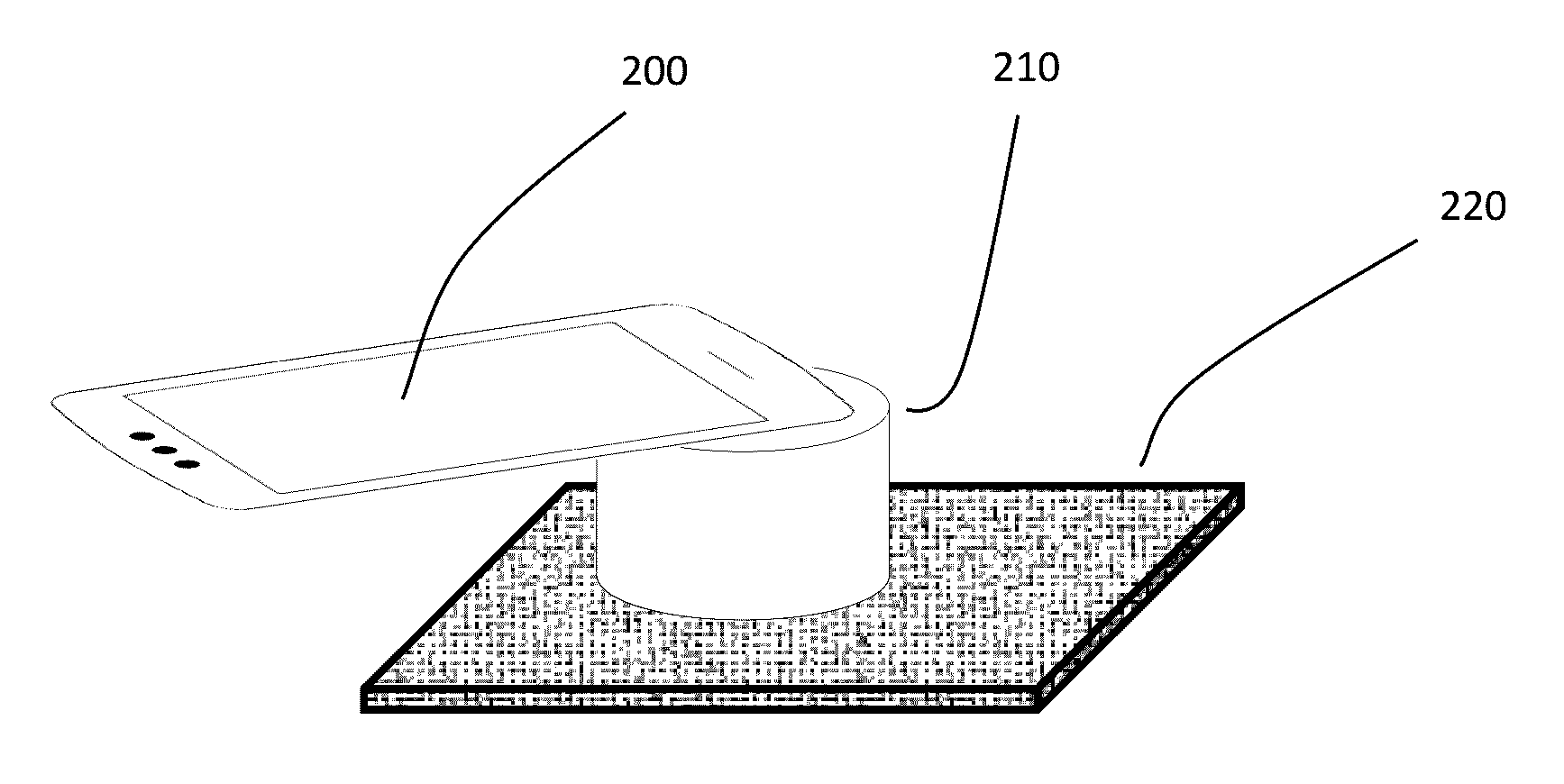

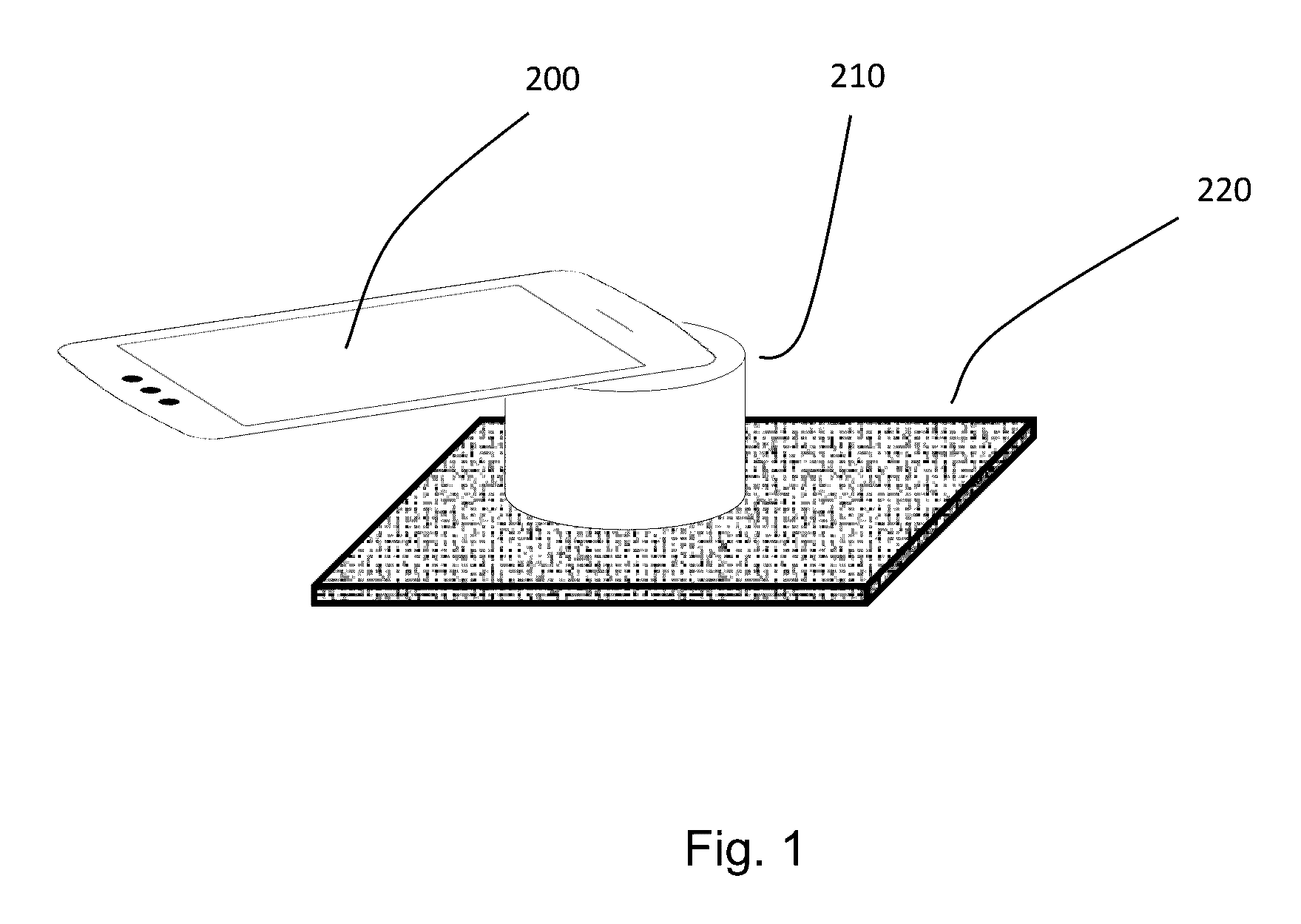

Image

Examples

example 2

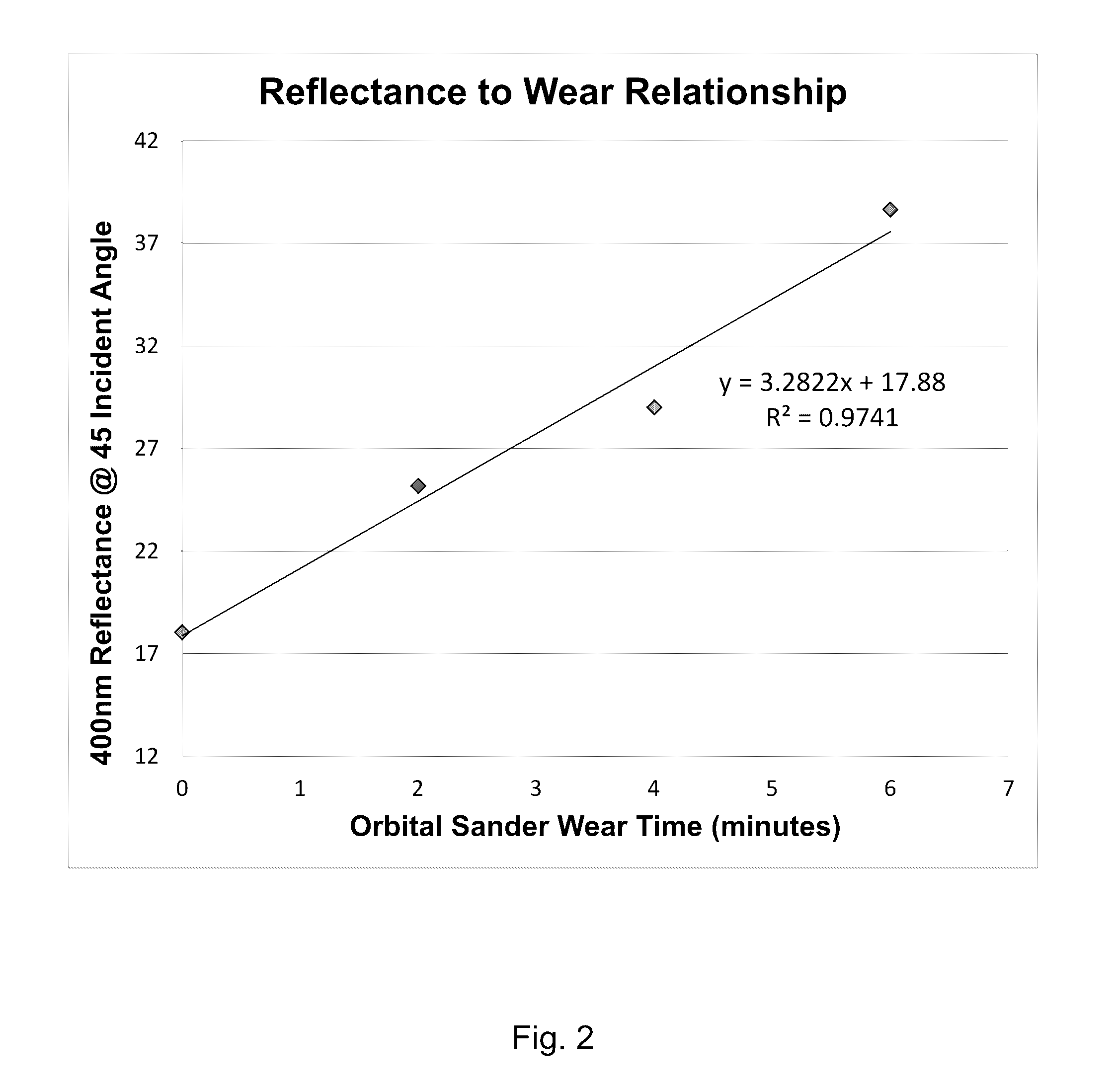

[0074]This example demonstrates the relationship between optical measurements and the loss of bite protection in a treated MCCUU fabric as the uniform is worn. Bite protection is based on two fundamental properties of a fabric; the first is the amount of bio-available permethrin insecticide on the surface of the fabric and the second is the physical barrier to biting insects that prevents them from biting the wearer. Both of these properties are affected by the abrasion and wear a uniform sustains during its life cycle. In this example optical measurement techniques are used on field-worn uniforms to establish a correlation with their protective performance. Below, we describe both the techniques we used to characterize the surface of the fabrics and the optical transmission properties.

[0075]Optical measurement analysis was first performed using data from Faulde et al., 2006 (Michael K. Faulde, “Factory-Based Permethrin Impregnation of Uniforms” Military Medicine, 171, 6:472, 2006; ...

example 3

[0090]predicting bite protection based on light transmission through field-worn samples. As the bulk weave of the fabric loosens and the gaps between the fibers increase, it is easier for the insects to bite through the uniform. The optical amount of light that passes through the uniform will increase as the fabric density decreases, opening small orifices for light to pass through. We measured the optical transparency of the field-worn MCCUU samples using a 3-watt white LED from a flashlight and a TAOS light-to-digital converter (TCS3472, TAOS, Plano, Tex.). The device used to make the measurements is shown in FIG. 12.

[0091]The area sampled was about 3.5 inches in diameter, encompassing a majority of the fabric sample. Approximately equal amounts of the different camouflage coloring were present in each of the sampled areas. Three replicates measurements were made on each sample. The data for the three replicates of the five samples is shown in FIG. 13. There are differences in the...

example 4

[0093]Bifenthrin treated uniforms: This example illustrates the method of the present invention when using bifenthrin as the insecticide, or active ingredient, in the functional fabric. Samples of Army Combat Uninforms (ACUs) treated with bifenthrin were used in this example.

[0094]Six ACU uniforms (jackets and trousers) that were previously treated with bifenthrin were used for textile washing experiments and then cut into fabric samples for both bifenthrin loading determination and mosquito efficacy testing. After the washing procedure, the samples fabric swatches were cut from locations around treated ACU jackets and trousers that included both the front and back of the uniform.

[0095]These uniforms had an original loading of bifenthrin of 0.135-0.176 mg / cm2. The textile samples were divided into 7 groups and washed either, 0, 1, 5, 10, 25, 40 or 50 times according to the procedure outlined in AATCC Test Method 135-2004. Samples of these uniforms at each wash level were analyzed to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com