Turbine engine blade made of composite material, and a method of fabricating it

a composite material and turbine engine technology, applied in the direction of machines/engines, weaving, mechanical equipment, etc., can solve the problems of high force, overhang of the inner blade platform obtained by the method, and the inability to incorporate both

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

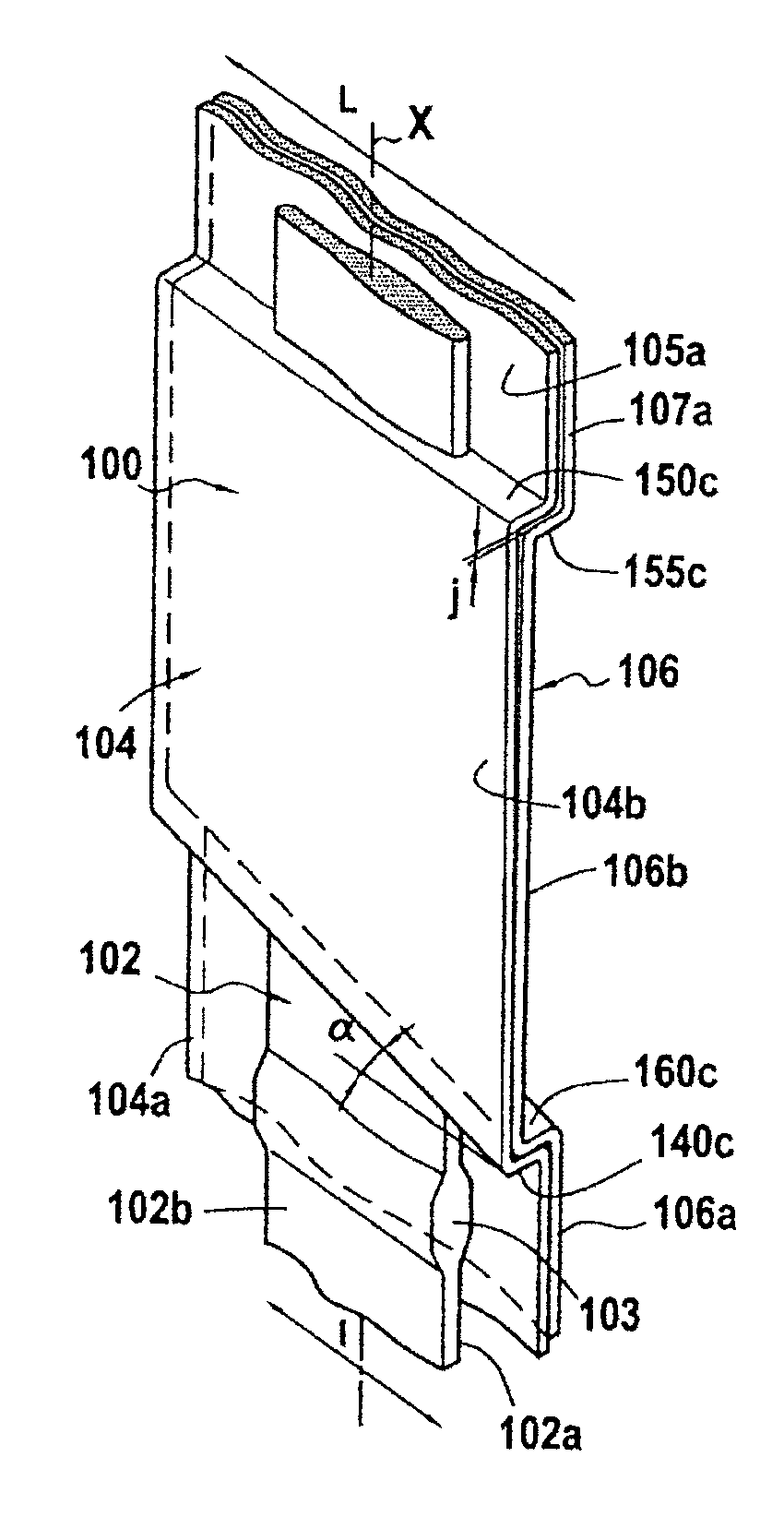

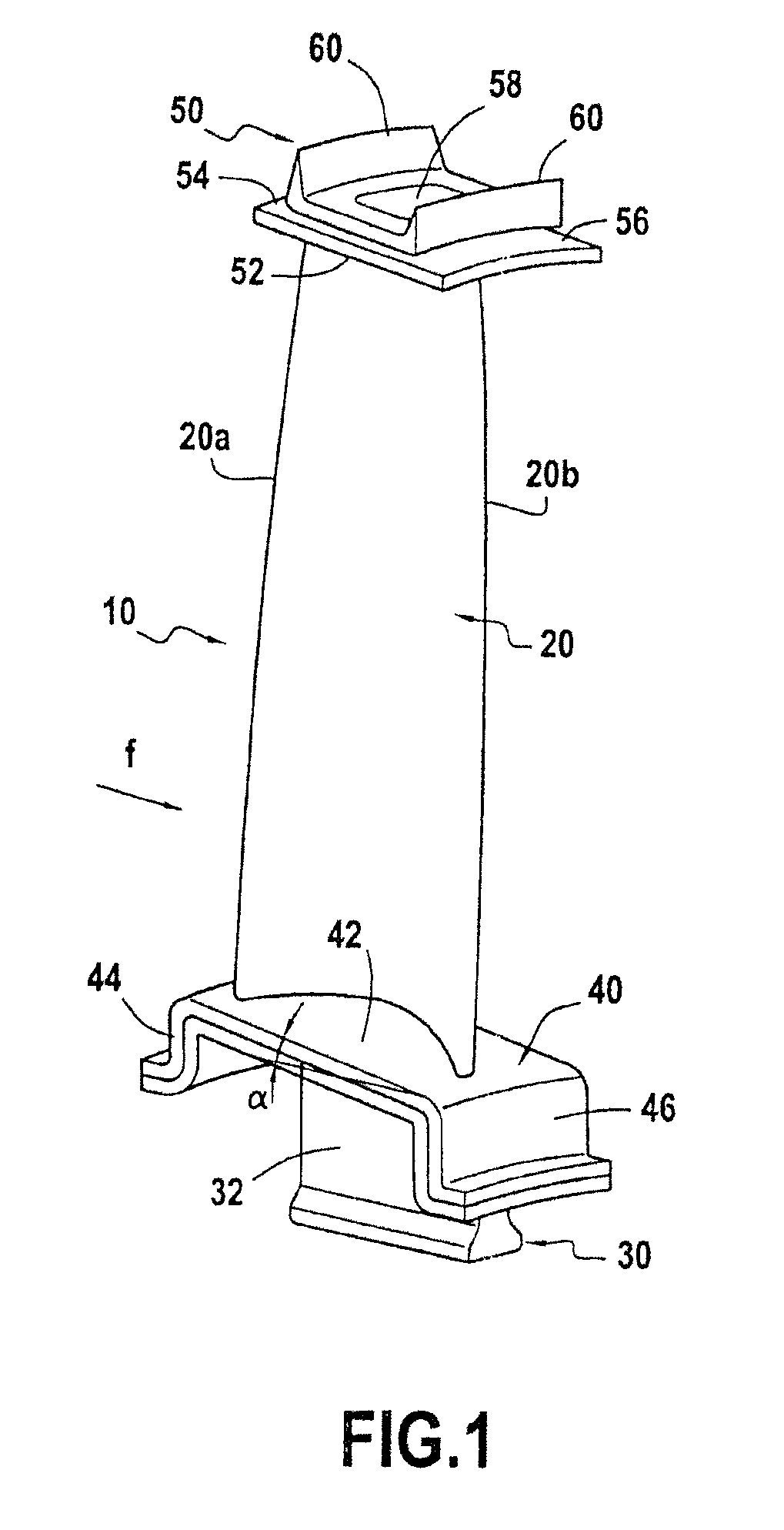

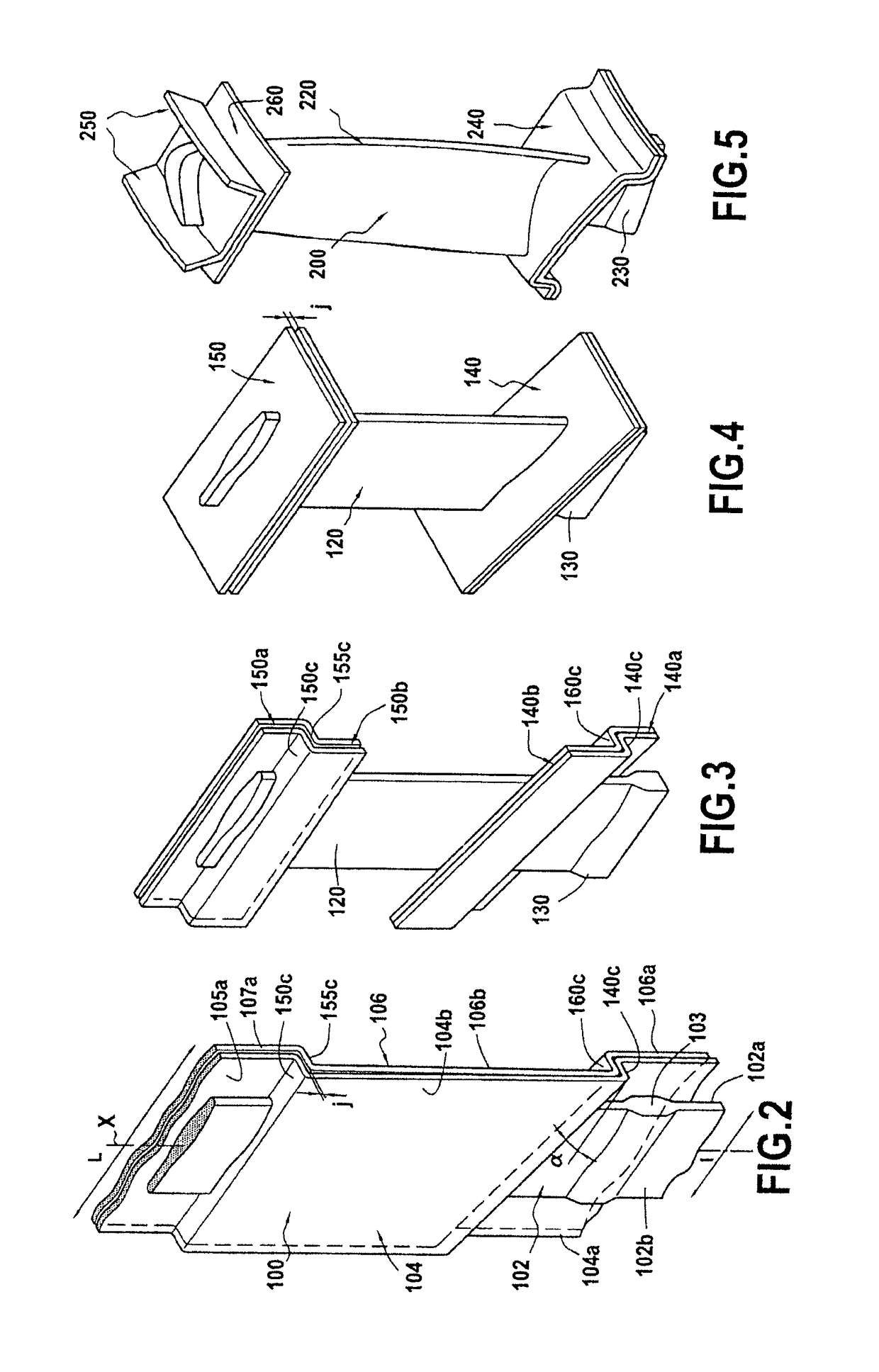

[0039]The invention is applicable to various types of turbine engine blade having inner and / or outer platforms incorporated therein, in particular compressor and turbine blades of various gas turbine spools, e.g. a low pressure (LP) turbine rotor blade such as that shown in FIG. 1.

[0040]The blade 10 of FIG. 1 comprises in well-known manner an airfoil 20, a root 30 constituted by a portion of greater thickness, e.g. having a bulb-shaped section and extended by a tang 32, an inner platform 40 situated between the tang 32 and the airfoil 20, and an outer platform 50 in the vicinity of the free end of the blade.

[0041]The airfoil 20 extends in a longitudinal direction between the inner platform 40 and the outer platform 50 and in cross-section it presents a curved profile of varying thickness between its leading edge 20a and its trailing edge 20b.

[0042]The blade 10 is mounted on a turbine rotor (not shown) by engaging the root 30 in a housing of complementary shape formed at the periphe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com