Tapping atomic force microscope with phase or frequency detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

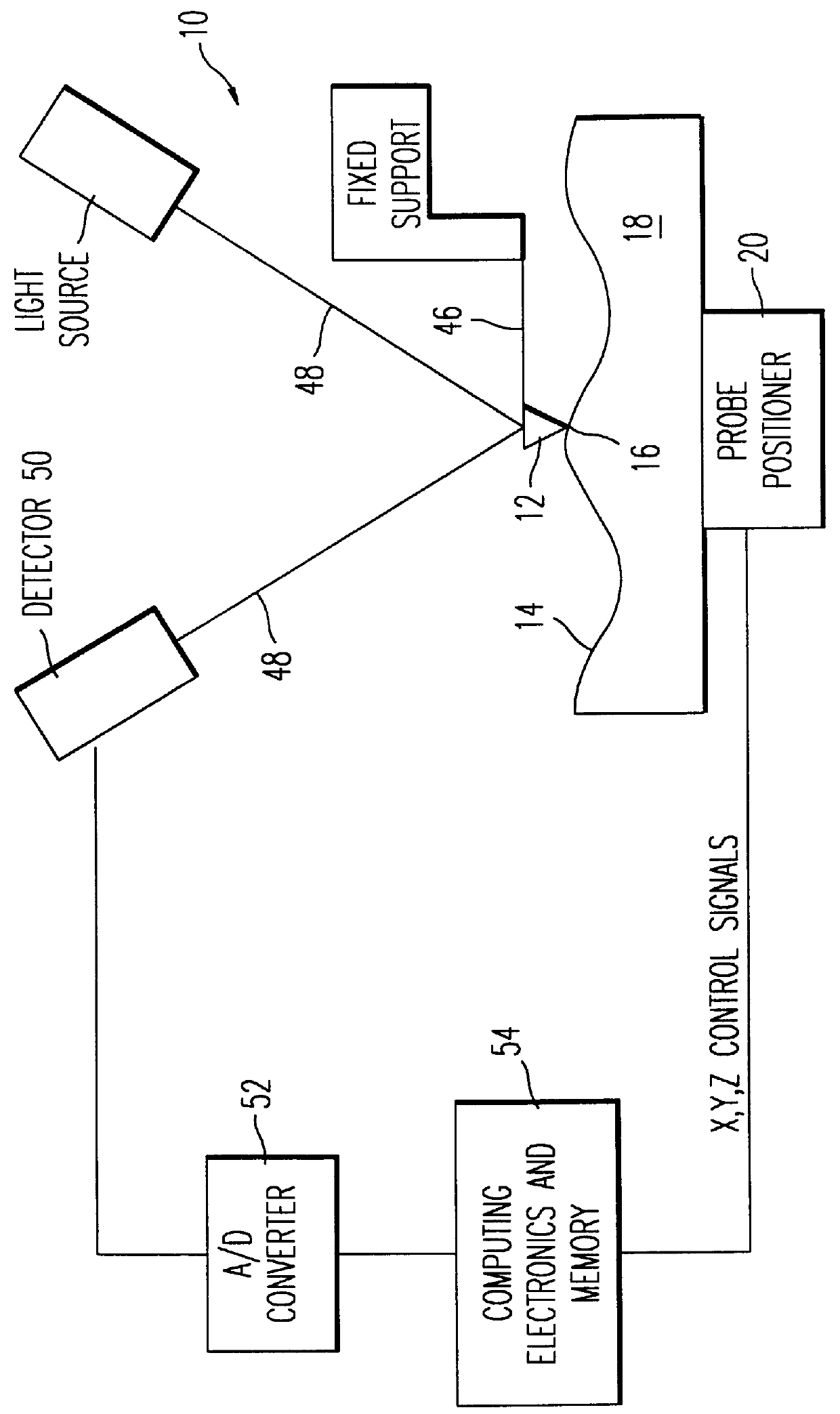

Embodiment Construction

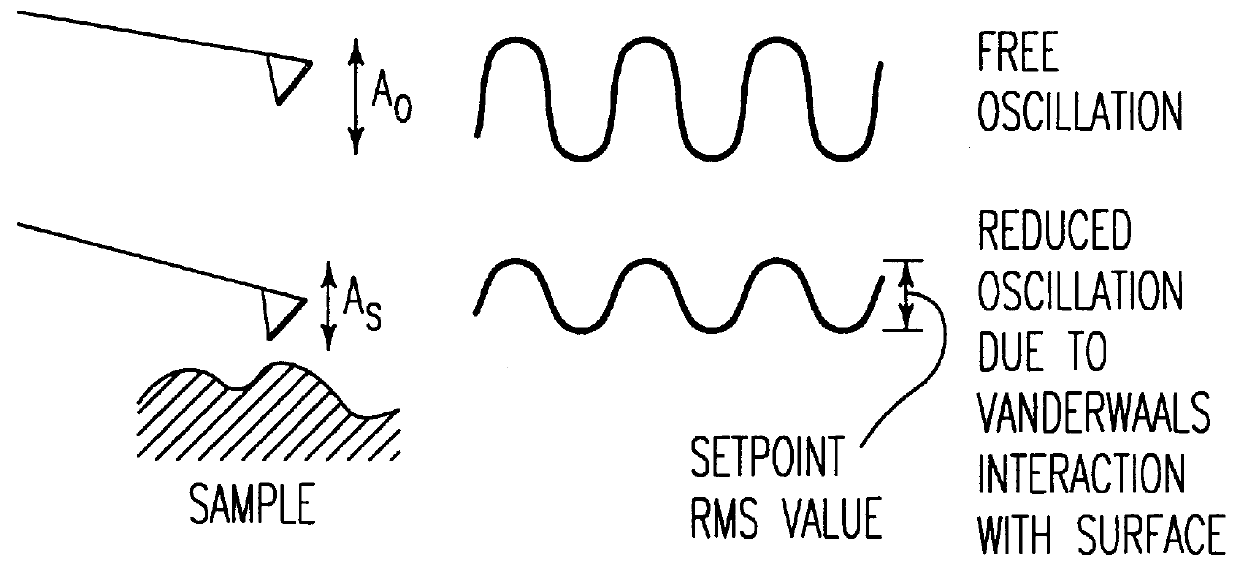

The present invention utilizes the inventors' discovery that if the probe is oscillated at or near one of the resonant frequencies of the lever, that in fact the probe tip has much less of a tendency to stick to the surface because a resonant system tends to remain in stable oscillation even if some damping exists. Thus the preferred embodiment of the present invention utilizes a resonant oscillation of the cantilever at sufficient oscillation amplitude to achieve the advantages described above without the probe becoming stuck to the surface. This preferred embodiment also provides many of the benefits of the non-contact AFM as described above.

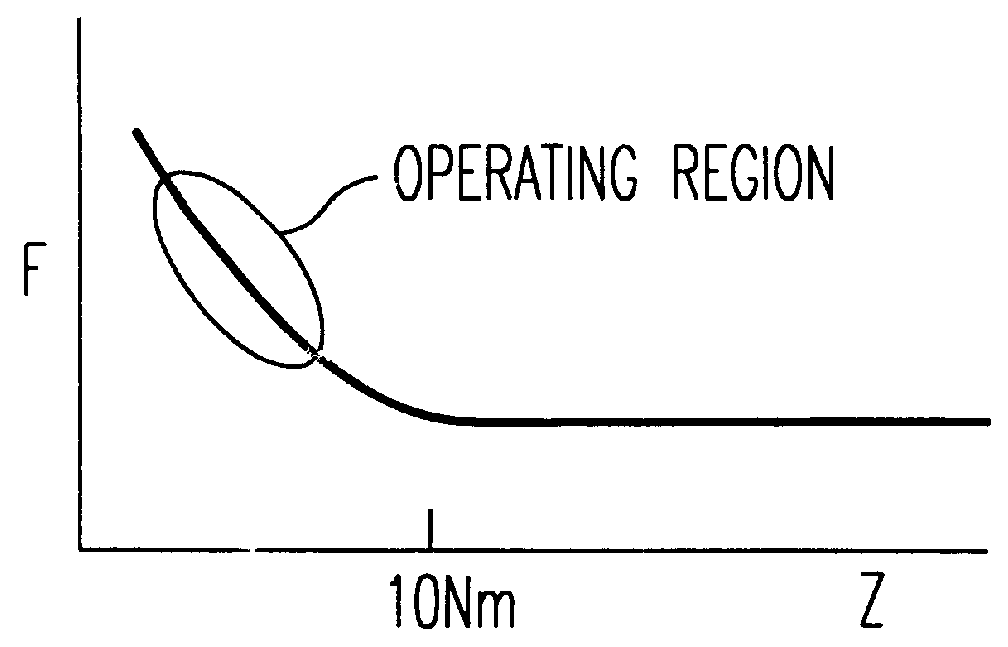

Existing development of AFM's using oscillation of the probes has been directed at avoiding surface contact, as described above, and as such is limited in practicality despite the potential advantages of the technique. For applications where the non-contact mode is desired, the inventors have found that the amplitude-distance curve of FIG. 6 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com