Snow removal tool

a technology of shovels and tools, applied in the field of hand tools, can solve the problems of bending under load, affecting the operation efficiency of hand tools, and critical steel weight, and achieve the effects of low cost, superior rigidity, and low cost manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

.Iadd.S .Iaddend.

Although the invention has been described in terms of a specific embodiment, it will be readily apparent to those skilled in this art that various modifications, rearrangements and substitutions can be made without departing from the spirit of the invention. The scope of the invention is defined by the claims appended hereto.

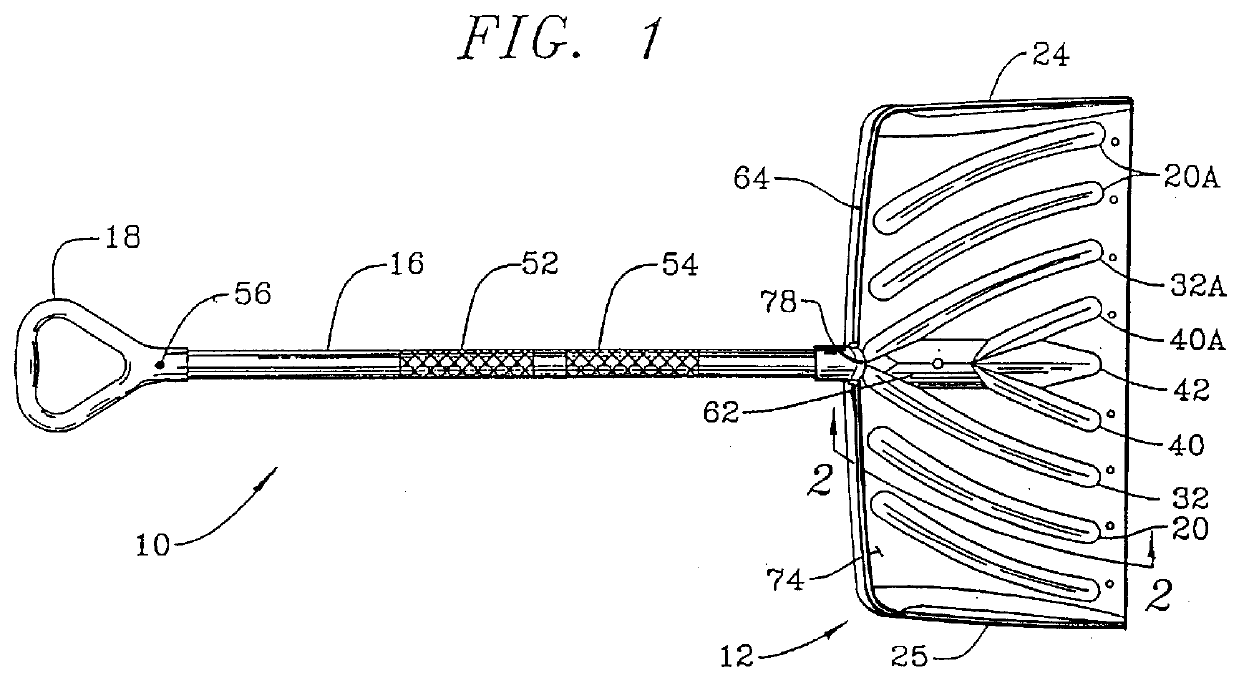

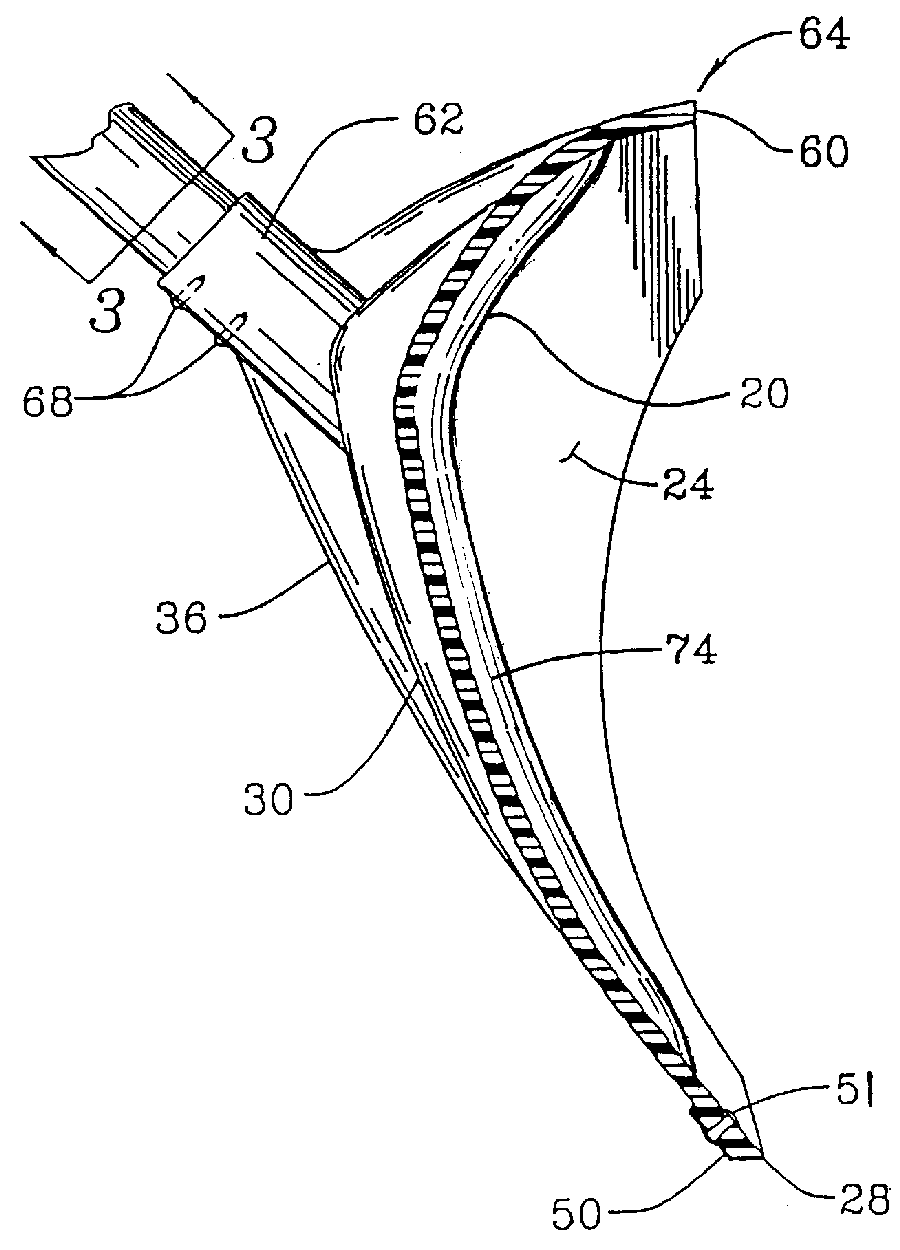

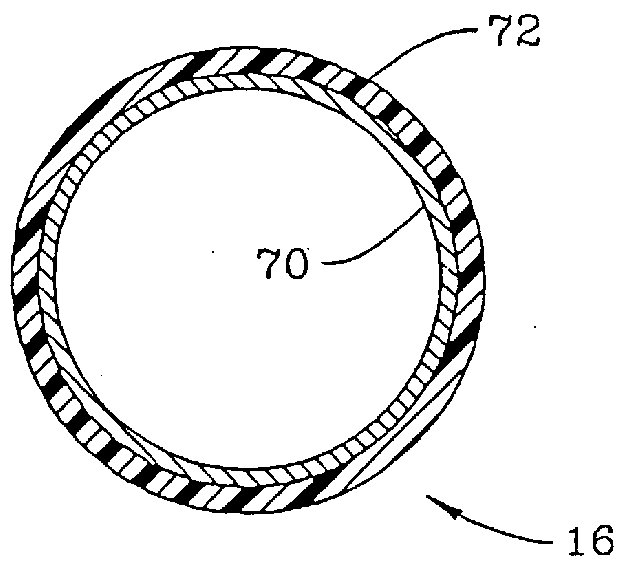

Referring to FIG. 1, a front view of a .Iadd.light weight, snow shovel assembly hand tool, snow tool, or shovel device comprising .Iaddend.pusher type snow shovel 10 is provided as a first embodiment of this invention generally defined by a rectangular pusher .Iadd.plastic .Iaddend.blade 12 .Iadd.or blade element .Iaddend.coupled to shaft 16 .Iadd.providing a shank of metal and plastic, .Iaddend.and .Iadd.to a plastic .Iaddend.handle 18 .Iadd.providing a handgrip.Iaddend.. The blade 12 is constructed of graphite impregnated polyethylene and has a unique shape that provides high strength when minimum thickness. The blade is defined by the use of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com