Soil sampling system with sample container rigidly coupled to drive casing

a sampling system and drive casing technology, applied in the direction of sealing/packing, instruments, borehole/well accessories, etc., can solve the problems of contaminated soils, serious environmental and health problems, and difficulty in identifying and treating contaminated soils, so as to improve the speed and efficiency of the system, convenient movement, reliable and effective sampling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

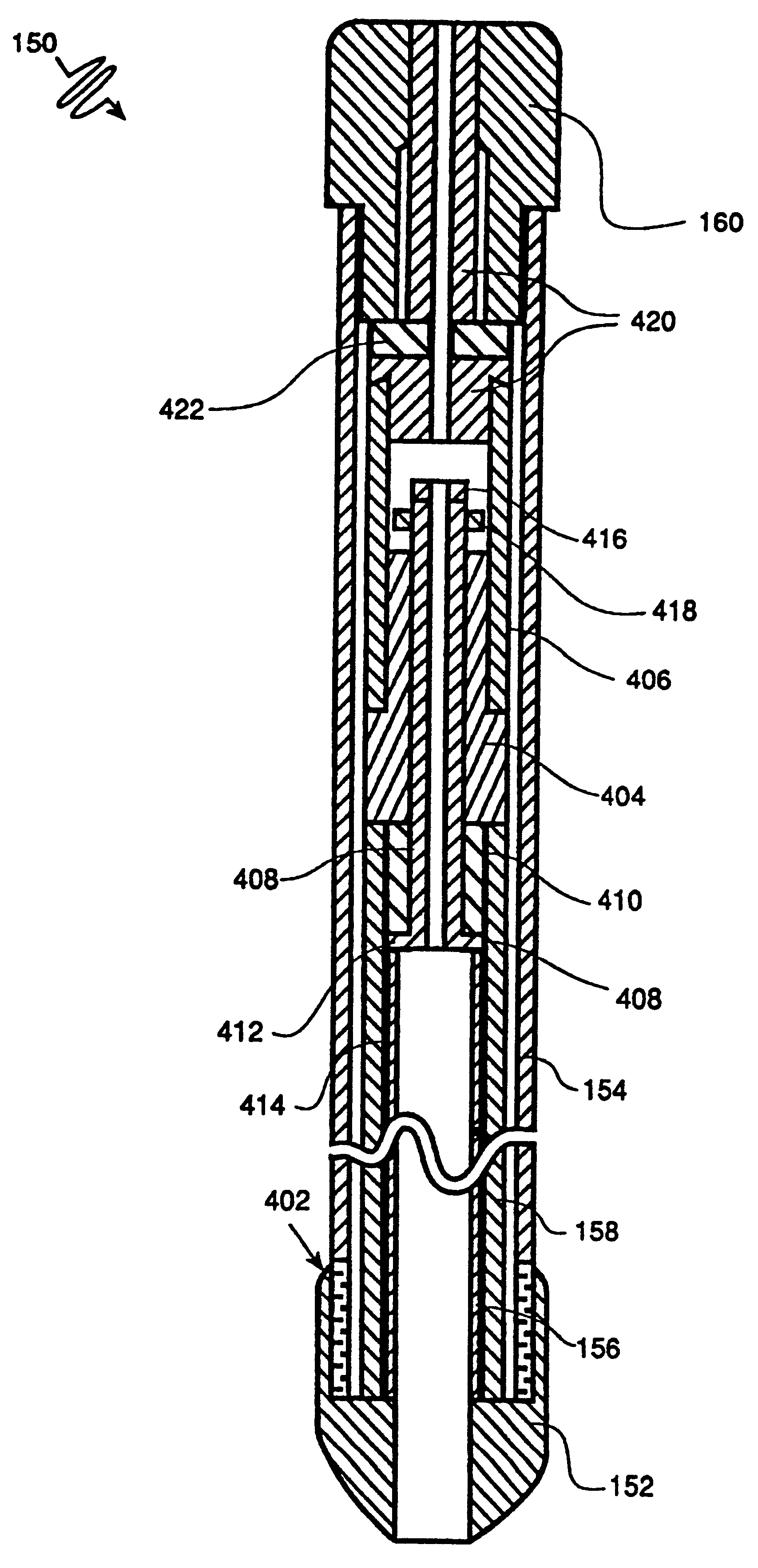

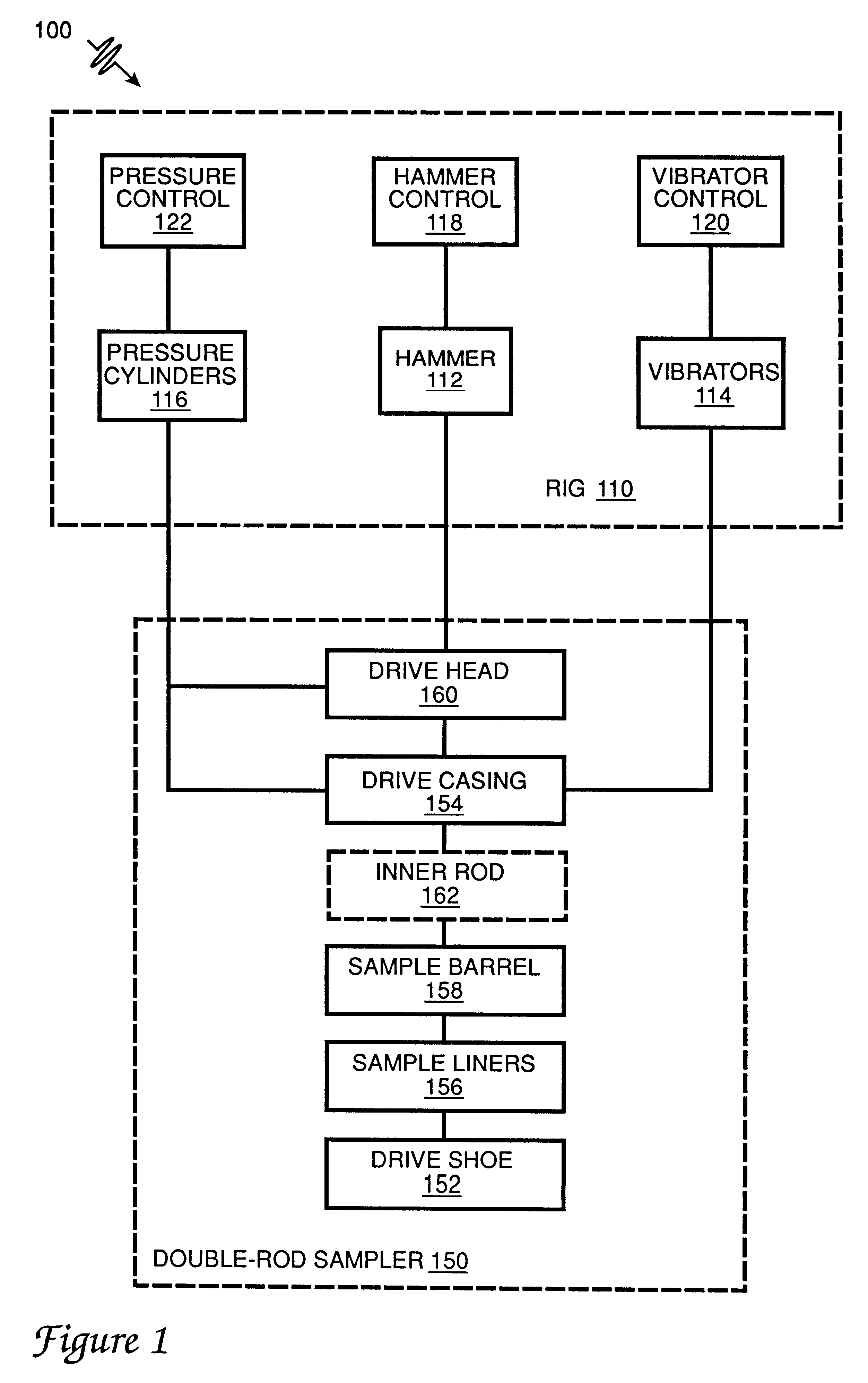

In accordance with the present invention, a double-rod soil sampling system 100 comprises a sampling rig 110 and a double-rod sampler 150, a shown in FIGS. 1 and 2. Sampling rig 110 includes three driving systems: a hydraulic hammer 112, hydraulic vibrators 114, and hydraulic pressure cylinders 116, shown in block diagram in FIG. 1. Respective drive controls include hammer controls 118 (including a hammer slide control that horizontally positions hammer 112 and a hammer pounding control the controls the pounding of hammer 112); a vibrator control 120; and a pressure control 122.

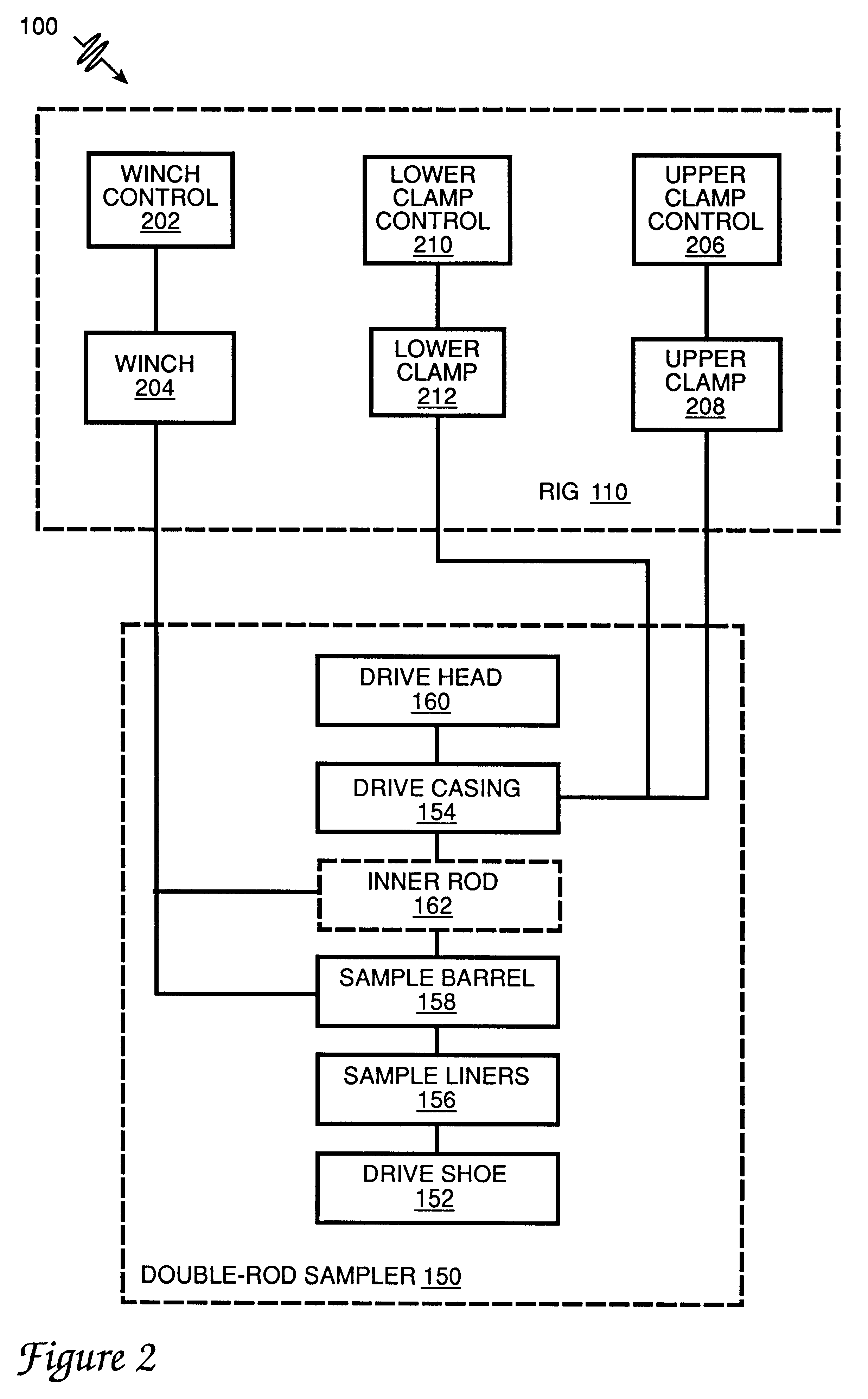

Sampling rig 110 also includes two retraction systems and their controls, as shown in block diagram in FIG. 2. A sample retrieval system includes a winch control 202 and a winch 204. A sampler retrieval system includes an upper clamp control 206, controlling upper clamp 208, and a lower clamp control 210, controlling lower clamp 212. The controls are mounted on the rig and control the respective driving and r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| frequency | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| angles | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com