Corrosion resistant PEM fuel cell

a fuel cell and corrosion resistance technology, applied in the direction of fuel cell details, fuel cells, electrochemical generators, etc., can solve the problems of difficult mechanical handling and processing of contact elements made therefrom, difficult to make very thin gas impervious plates, and quite fragile graphite, etc., to achieve low electrical resistivity and not easy to crack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

The invention will be better understood when considered in the light of the following detailed description thereof which is given hereafter in conjunction with the following drawings of which:

BRIEF DESCRIPTION OF THE DRAWINGS

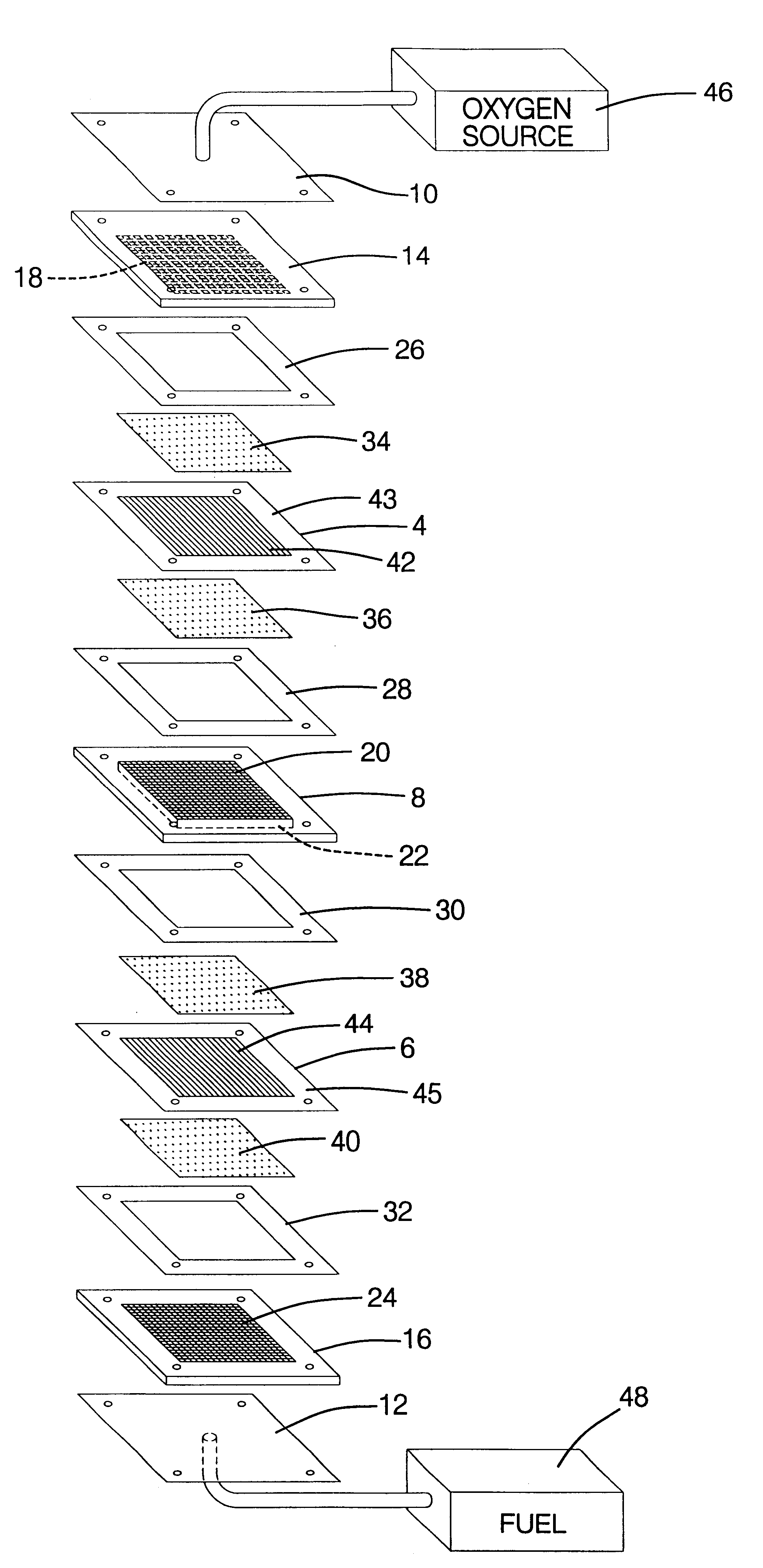

FIG. 1 is a schematic, isometric, exploded view of a bipolar PEM fuel cell;

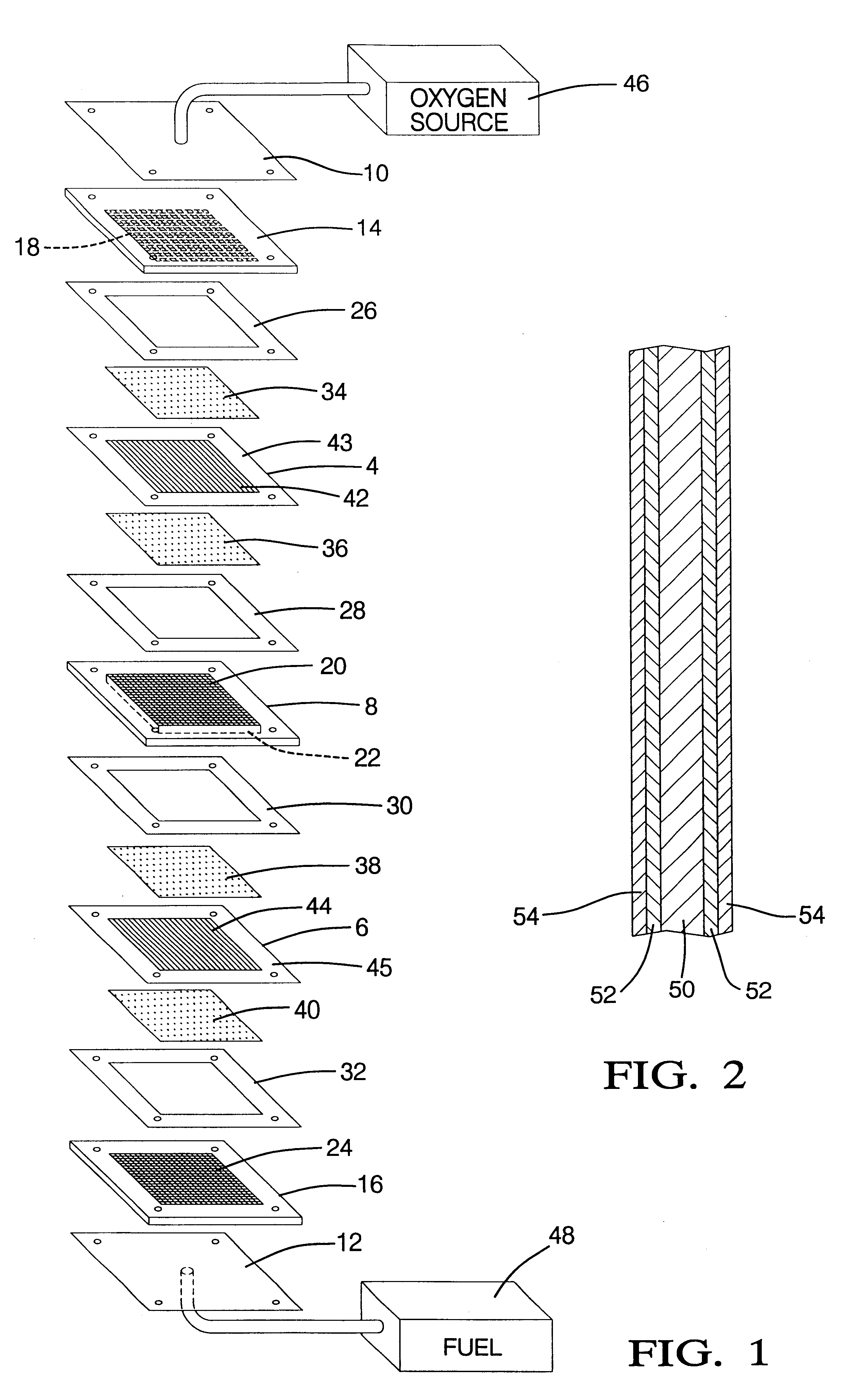

FIG. 2 is sectioned view through the bipolar plate of FIG. 1;

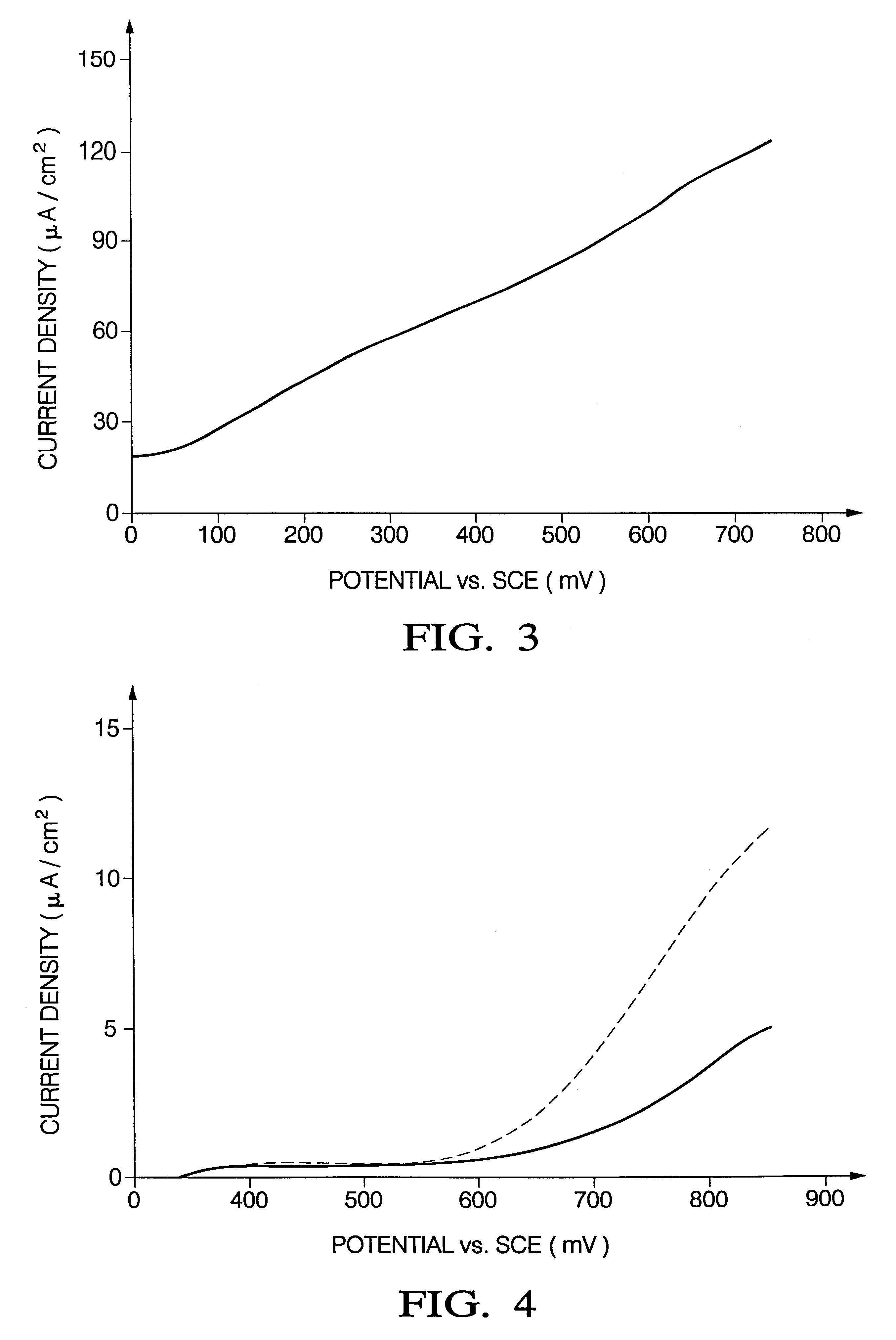

FIG. 3 is a potentiodynamic polarization curve of a bare aluminum 6061-T6 in a simulated fuel cell environment;

FIG. 4 are typical potentiodynamic polarization curves for aluminum coated with (a) just stainless steel, and (2) both stainless steel and TiN in a simulated fuel cell environment;

FIG. 5 is a current vs. time plot of a TiN / SS-coated aluminum substrate at a constant anodic polarization of 760 mV vs. SCE; and

FIG. 6 is a measured resistance plot for different lengths of "as-deposited"and " post corrosion testing " of a TiN film.

FIG. 1 depicts a two cell, bipolar PEM fuel cell having a pair of membrane-electrode-assemblies ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pH | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com