Aqueous based composition containing dibasic ester and thickening agent for removing coatings

- Summary

- Abstract

- Description

- Claims

- Application Information

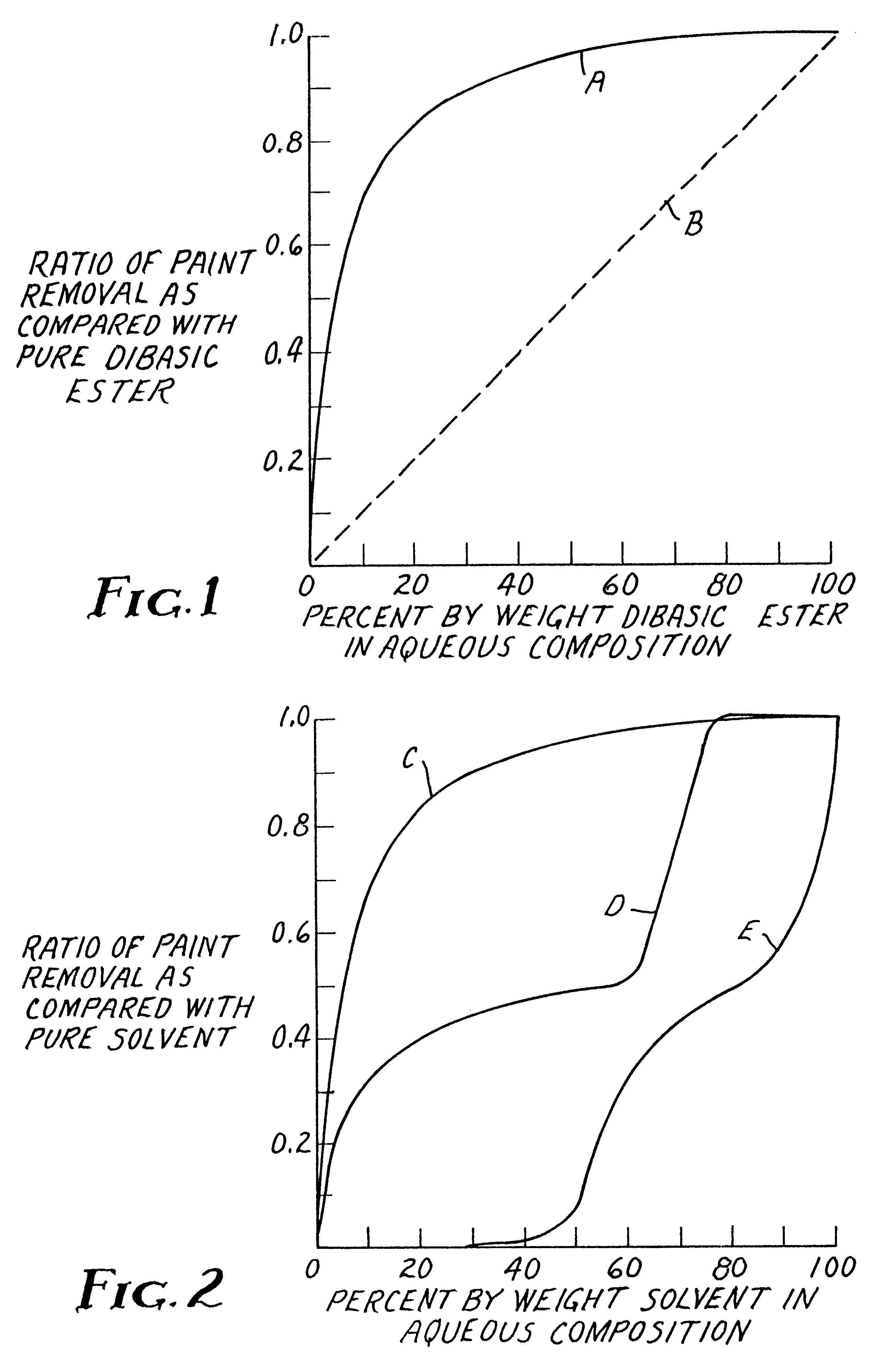

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

The following ingredients in the amounts indicated were used to prepare a composition of this invention:

Amount (parts by Ingredient weight) Clay thickening agent (amine treated 0.8 magnesium aluminum silicate, "Veegum Pro", available from R. T. Vanderbilt Co., Inc., Norwalk, CT) Cellulose thickening agent (hydroxypropyl 1.0 methylcellulose, "Methocel K15MS", available from Dow Chemical Co., Midland, MI) Surfactant (polypropylene oxide-polyethylene 0.05 oxide copolymer, "Pluronic P104", available from BASF Wyandotte Corp. Wyandotte, MI) Dibasic ester (DBE-3, a mixture containing 89% 24.5 dimethyl adipate, 10% dimethyl glutarate, 0.5% dimethyl succinate, 0.1% methanol, available from E. I. du Pont de Nemours and Co., Wilmington, DE) Water 73.65

The clay thickening agent was added to the water and the mixture stirred at a constant rate at 78.degree. C. for 30 minutes. The cellulose thickener was then added with stirring and the resulting mixture was stirred for an additional 10 minutes....

examples 2-7

The following table sets forth ingredients and the amounts thereof used to prepare compositions within the scope of this invention. The compositions were prepared in the same manner as in Example 1, with the exception that xanthan gum was added at the same time as the cellulose thickener.

TABLE I Con- Con- Amount (parts by weight) trol trol Ingredient 2 3 4 5 6 7 A B Clay 0.27 0.25 0.25 0.25 0.25 0.20 -- -- thickening agent.sup.1 Clay -- -- -- -- -- -- 1.0 -- thickening agent.sup.2 Cellulose 0.65 0.58 0.59 0.59 0.5 0.49 1.0 -- thickening agent.sup.3 Xanthan 0.92 0.82 0.79 0.79 0.79 0.69 -- -- gum.sup.4 Dibasic 9.8 19.7 -- -- -- 4.9 -- -- ester.sup.5 Dibasic -- -- 24.6 -- -- -- -- 100 ester.sup.6 Dibasic -- -- -- 24.6 -- -- -- -- ester.sup.7 Dibasic -- -- -- -- 24.6 -- -- -- ester.sup.8 Surfactant.sup.9 0.1 0.1 0.1 0.1 0.1 0.1 0.07 -- Water 88.26 78.55 73.67 73.67 73.67 93.62 97.93 -- .sup.1 Colloidal magnesium aluminum silicate, "Veegum T", available from R. T. Vanderbilt Co., Inc. ....

examples 8-15

The following table sets forth ingredients and the amounts thereof used to prepare compositions within the scope of this invention. The compositions were prepared in the same manner as in Example 1.

TABLE III Amount (parts by weight) Ingredient 8 9 10 11 12 13 14 15 Clay 1.65 2.16 2.16 2.16 2.16 2.16 2.16 2.16 thickening agent.sup.1 Surfactant.sup.2 0.9 .144 0.9 0.9 .144 .144 .144 .144 Surfactant.sup.3 1.1 .176 1.1 1.1 .176 .176 .176 .176 Dibasic 40.3 41.0 39.32 34.3 31.0 24.00 16.12 6.12 ester.sup.4 Xanthan 0.39 0.5 0.5 0.5 0.5 0.5 0.5 0.5 gum.sup.5 Cellulose 0.70 0.9 0.9 0.9 0.9 0.9 0.9 0.9 thickening agent.sup.6 Water 55.0 55.12 55.12 60.14 65.12 72.12 80.0 90.0 .sup.1 Magnesium aluminum silicate, "Veegum D", available from R. T. Vanderbilt Co., Inc. .sup.2 Sorbitan monooleate, "Span 80", available from ICI Americas, Inc. .sup.3 Polyoxyethylene 20 sorbitan monooleate, "Tween 80", available from ICI Americas, Inc. .sup.4 DBE-3, a mixture containing 89% dimethyl adipate, 10% dimethy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com