Liquid crystal display element and micro-lens arrangement and a display using the same

a technology of liquid crystal display elements and micro-lens arrays, which is applied in the direction of color television details, identification means, instruments, etc., can solve the problems of reducing light utilization efficiency, difficult to increase light intensity, and large effect of light shielding portions, so as to improve the focusing characteristic of micro-lens arrays and smooth display. , the effect of increasing light utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

second embodiment

FIG. 8 is a perspective view of the liquid crystal display element of the invention. In FIG. 8, like elements corresponding to those in FIG. 1 are identified by the same reference numerals, and will not be described in detail.

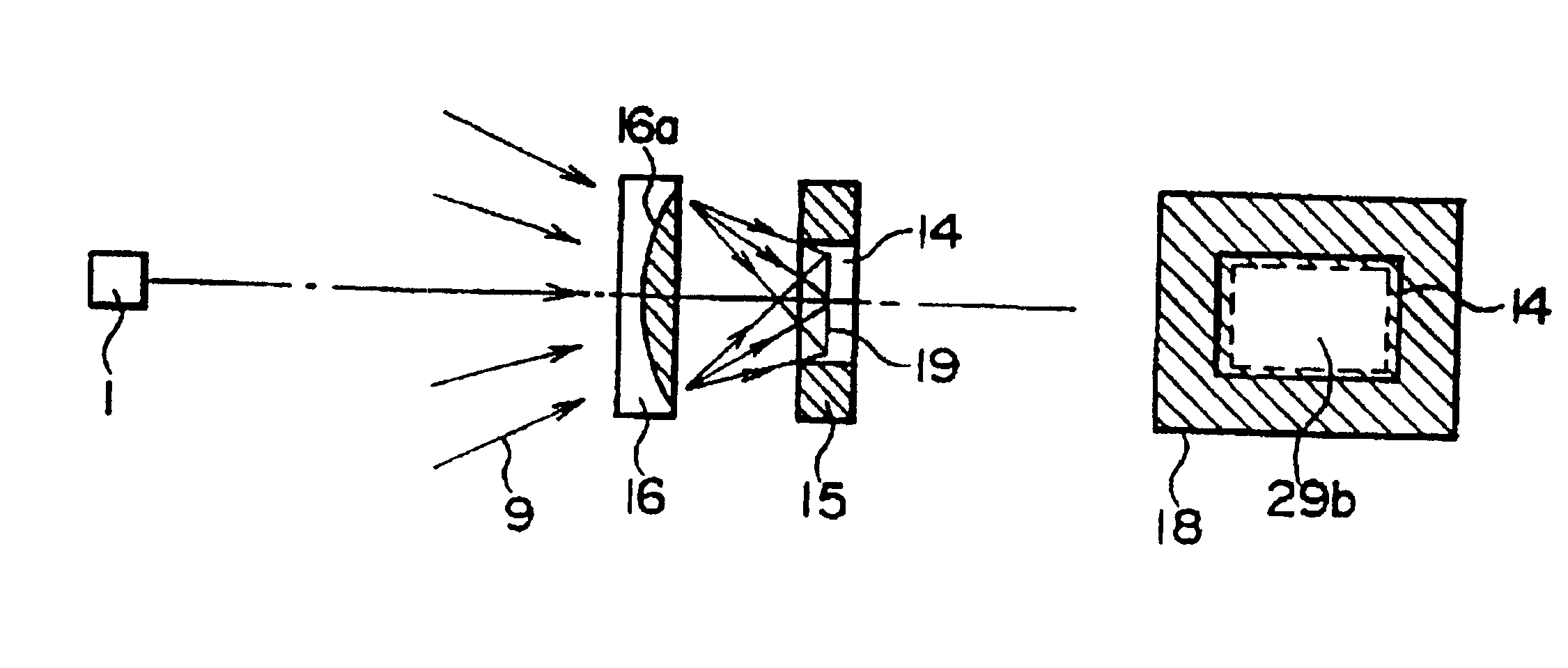

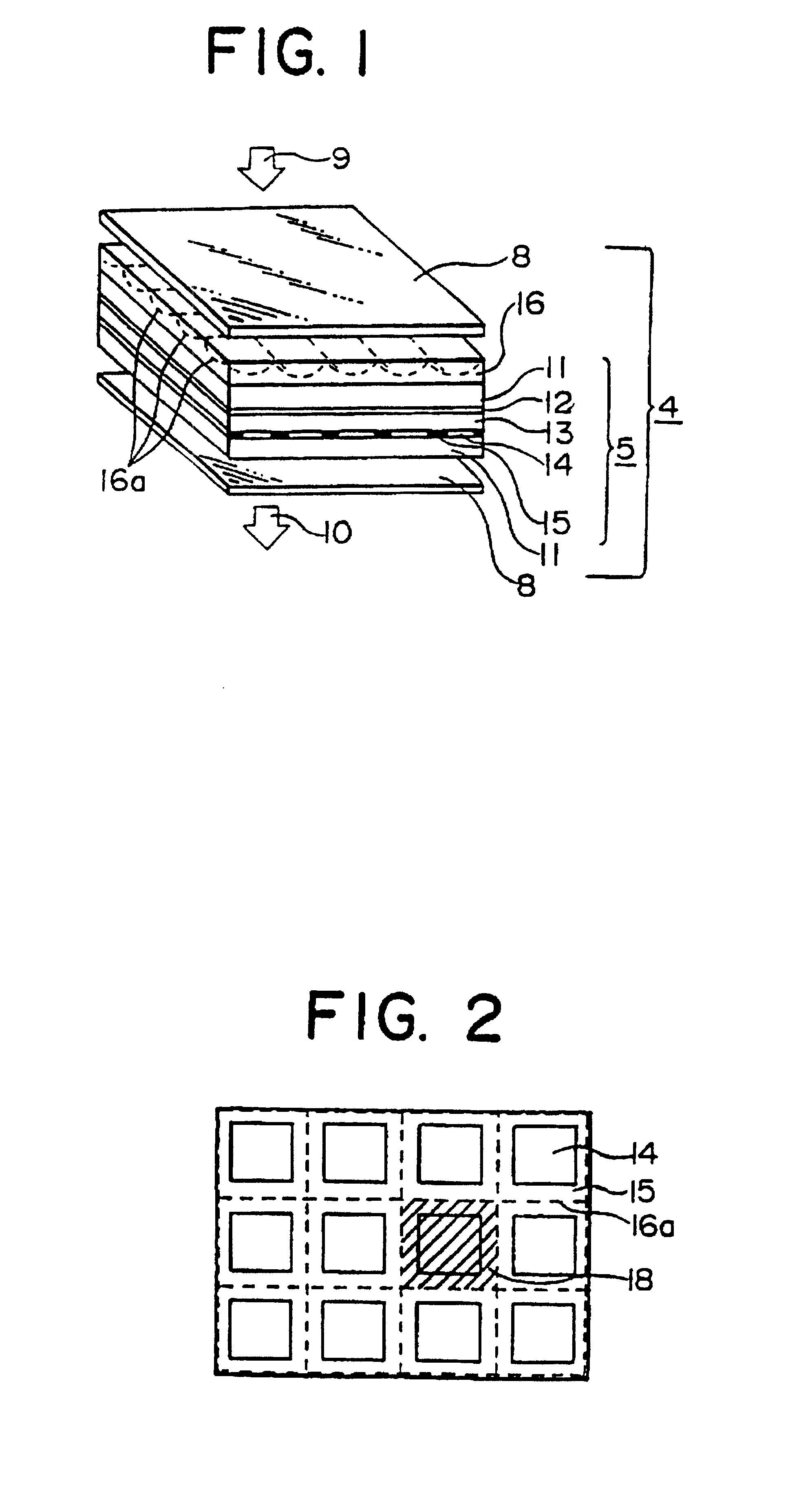

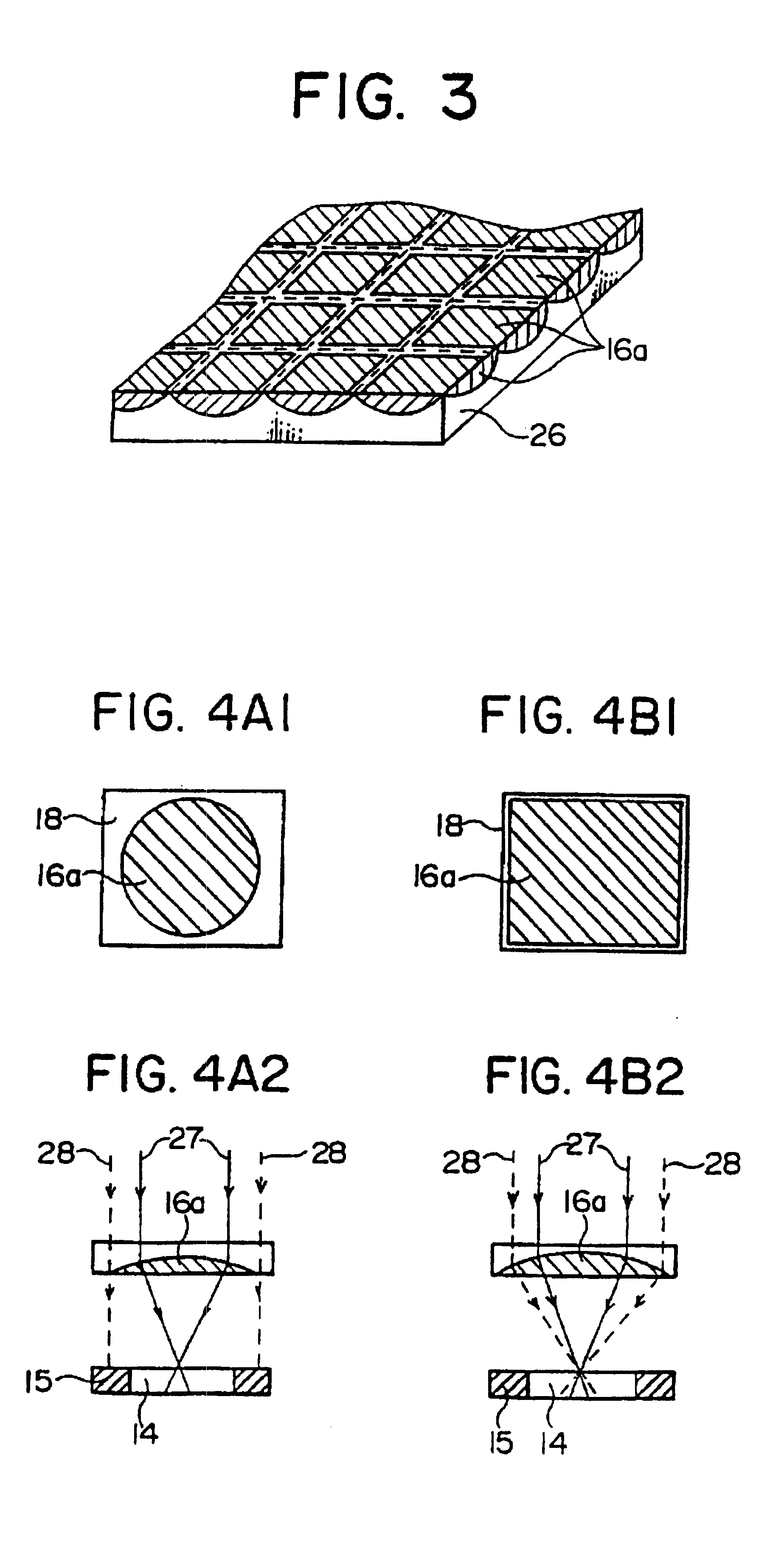

Referring to FIG. 8, there is shown the flat-plate micro-lens array 16 which is formed in the one transparent substrate 11 of the liquid crystal cell 5 (integrally formed with the substrate 11). The structure of liquid crystal display element of this embodiment is different in this point from that of FIG. 1. In other words, the transparent substrate 11 which can be apparently maintained at a high precision as described above is satisfactory for the flat-plate micro-lens array 16 of the refractive index distribution type, and thus it is formed within the one transparent substrate 11. The shape of each lens (unit lens 16a) of the micro-lens array 16 is the same as that of the region 18 corresponding to one picture element of the liquid crystal cell shown in FIG. ...

first embodiment

FIGS. 14A, 14D to FIG. 16 show various constructions of the illumination optical system in the liquid crystal display element of the invention shown in FIGS. 13A to 13D.

In FIGS. 14A to 14D, there are shown a concave mirror 2a of a elliptic shape in cross-section or of the so-called multimirror, and a concave mirror 2b of a parabolic shape in cross-section. In the illumination optical system of FIG. 14A, the light emitted from the light source 1 and reflected from the elliptic-shape concave mirror 2a and the light emitted from the light source at about the focal point (hereinafter, called the front-side elliptic focal point) near the center of the concave mirror 2a are focused at around the focal point (hereinafter, called the back-side elliptic focal point) of the elliptic-shape concave mirror 2a near the liquid crystal display element 4. Thus, the condenser lens group 3 as a concave lens having a predetermined positive power is provided near the back-side elliptic focal point on th...

third embodiment

FIG. 22 shows the liquid crystal display using the liquid crystal display element according to the embodiment of the invention as the light bulb.

In FIG. 22, three liquid crystal display elements according to this invention are used to correspond to three colors of R (red), G (green) and B (blue), or so-called three primaries of color and to constitute a three-plate projection type liquid crystal display. Referring to FIG. 22, the light emitted from the light source 1 of, for example, metal halide, xenon or halogen is, directly or after reflection from the concave mirror 2, passed through an infrared-cut filter 45 which reflects infrared light and allows visible light to be passed therethrough. Then, the visible light is incident to the condenser lens group 3 and thereby made substantially parallel to the optical axis. The parallel light exiting from the condenser lens group is fed to a B (blue)-reflecting dichroic mirror 40a which is tilted at 45.degree. to the optical axis. Thus, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| optical length | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| transparent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com