Method and apparatus for an integrated laser beam scanner using a carrier substrate

a laser beam scanner and carrier substrate technology, applied in the direction of instruments, optical elements, electromagnetic radiation sensing, etc., can solve the problem that current techniques do not allow wafer-scale integration of light-emitter and mems devices, and achieve the effects of reducing complexity, improving functionality, and simplifying printing systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

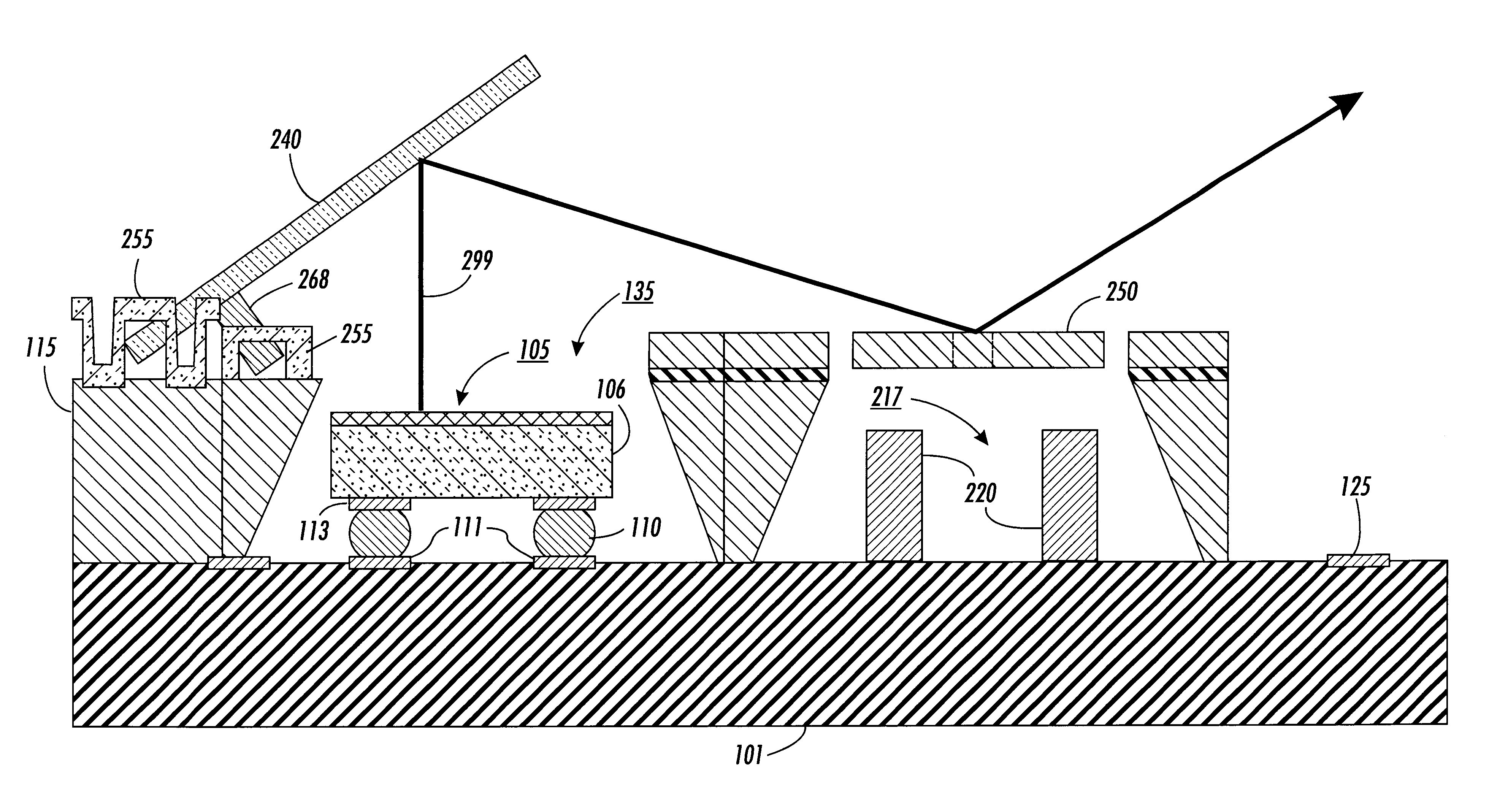

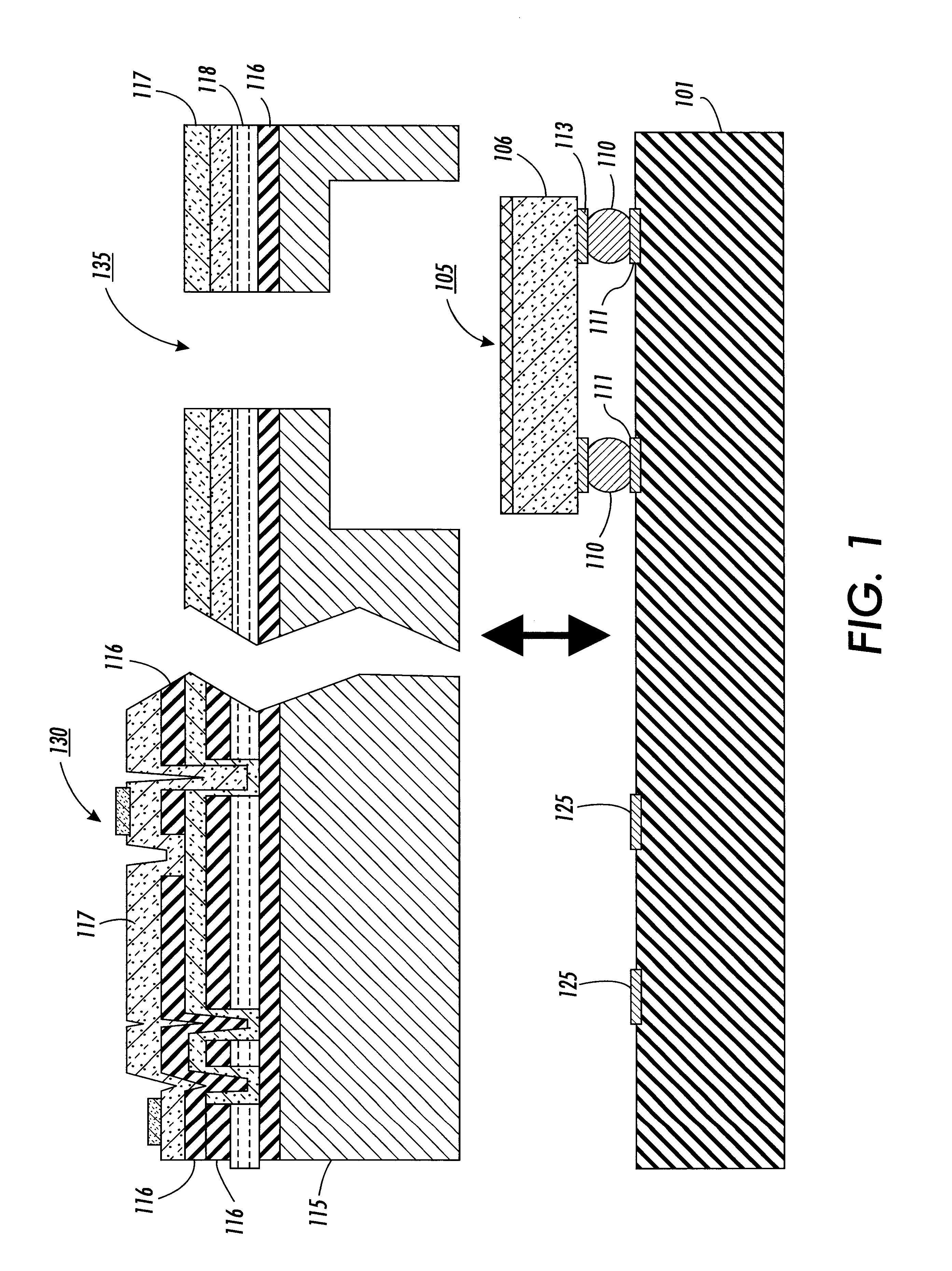

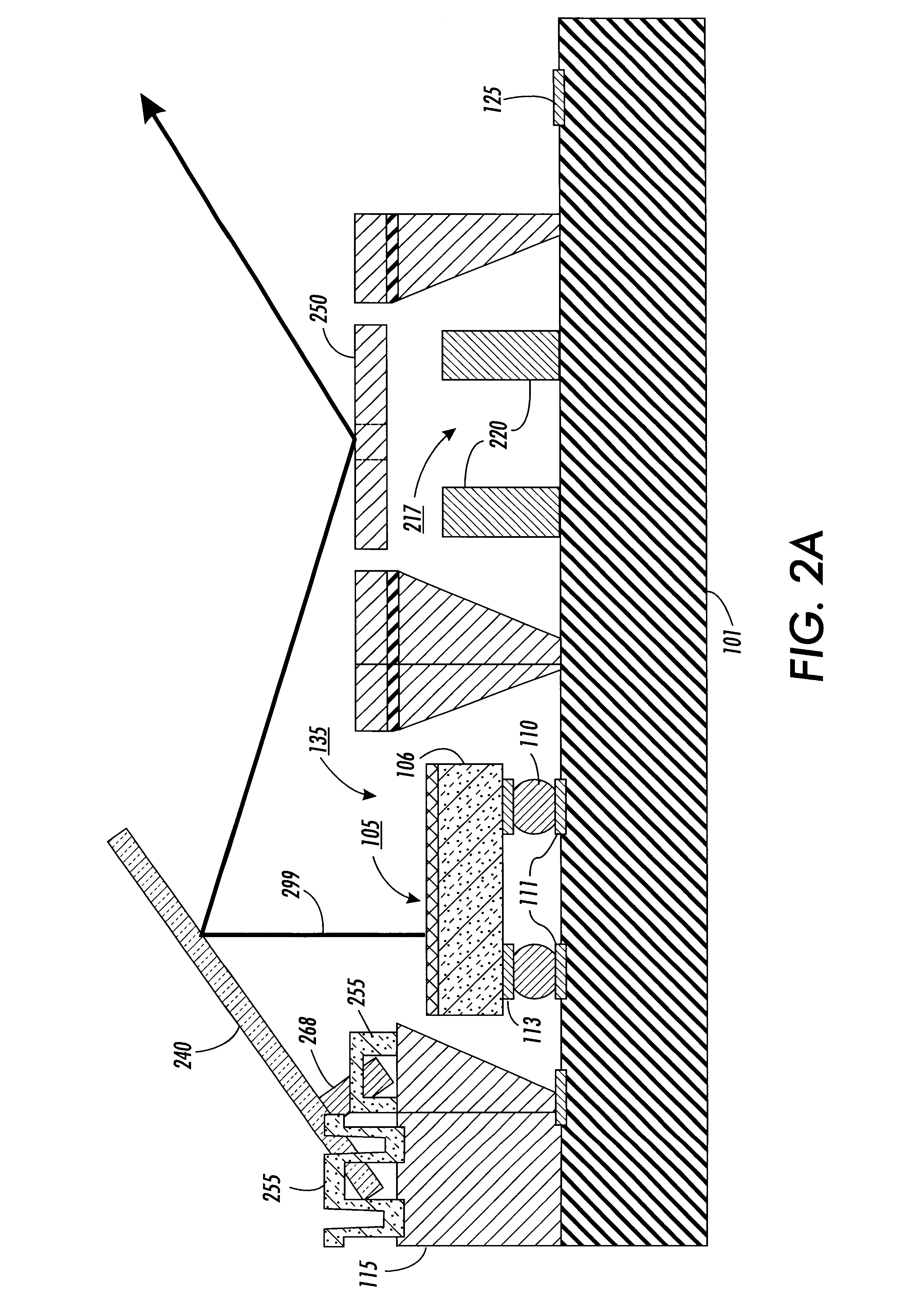

An embodiment in accordance with the present invention is shown in FIG. 1 and FIG. 2a. A laser beam scanner consisting of single crystal silicon (SCS) deflecting mirror 240 and torsional mirror 250 is integrated with laser diode or light emitting diode 105. Using solder bump bonding methods, completed and tested laser diodes 105 are bonded to glass or silicon carrier substrate 101. Carrier substrate 101 is aligned and bonded to MEMS substrate 130 containing the MEMS layers. Bonding of laser diode 105 to carrier substrate 101 completely partitions the bonding process from the MEMS layers. This complete partition eliminates possible conflicts between the conditions needed for solder bump bonding, such as the use of solder flux, and preserves the integrity of the MEMS layers. Typically, solders such as Pb / Sn, Au / Sn, or In / Sn are evaporated selectively onto wettable metal bonding pads 111 onto substrate 101 and reflowed to form hemispherical solder bumps 110. Solder bumps 110 are contac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com