High speed method of aligning cutting lines of a workplace using patterns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

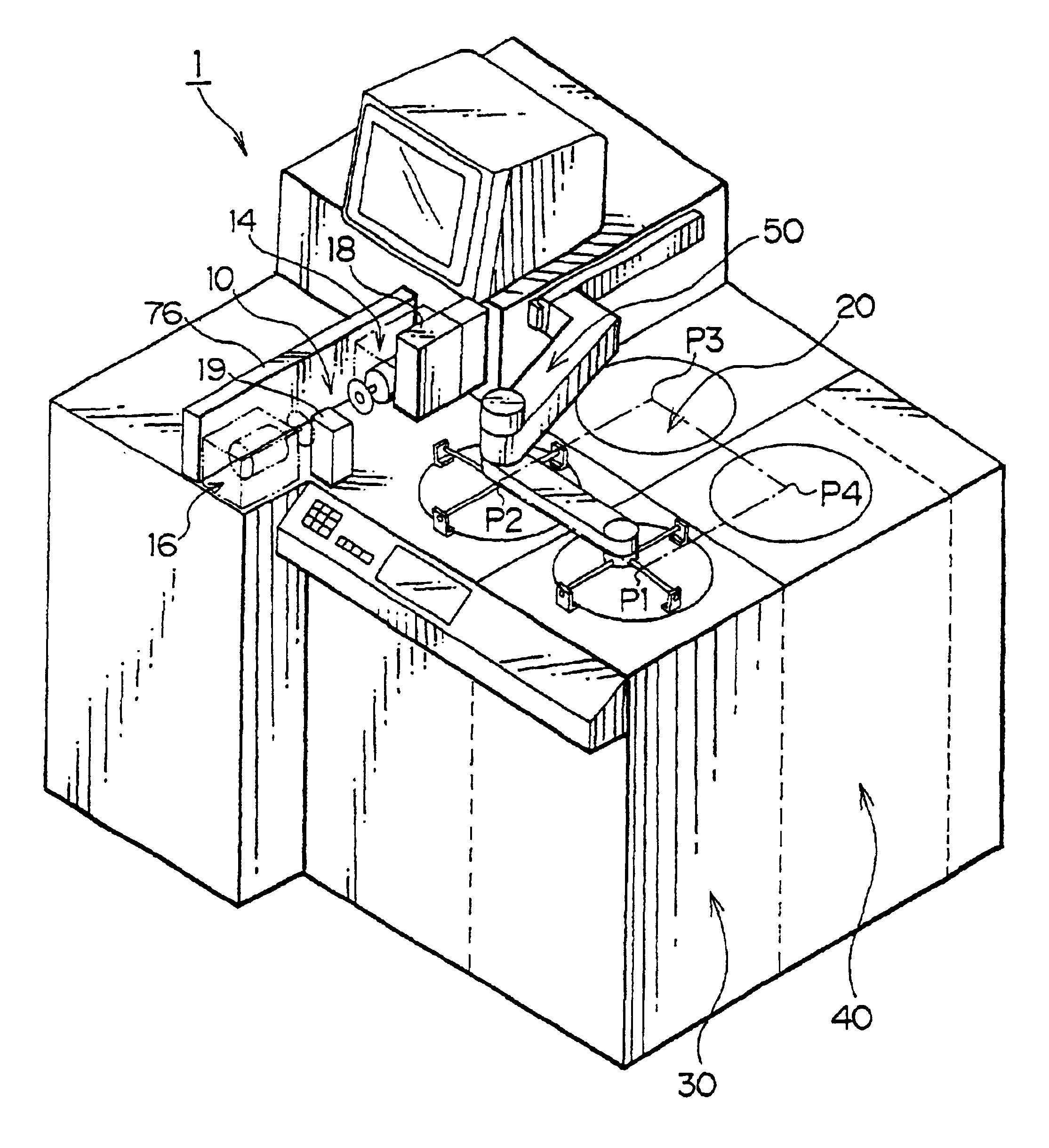

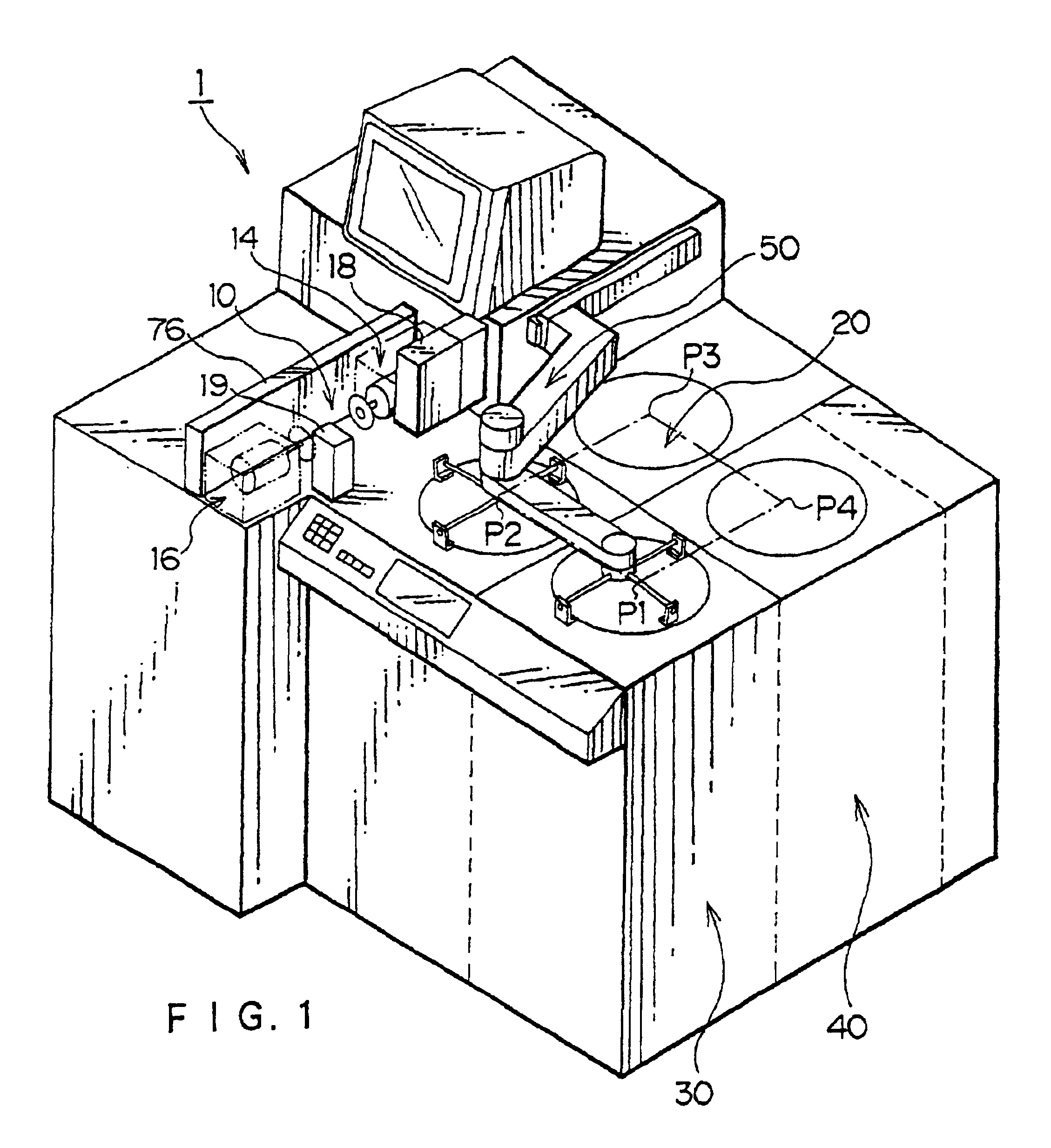

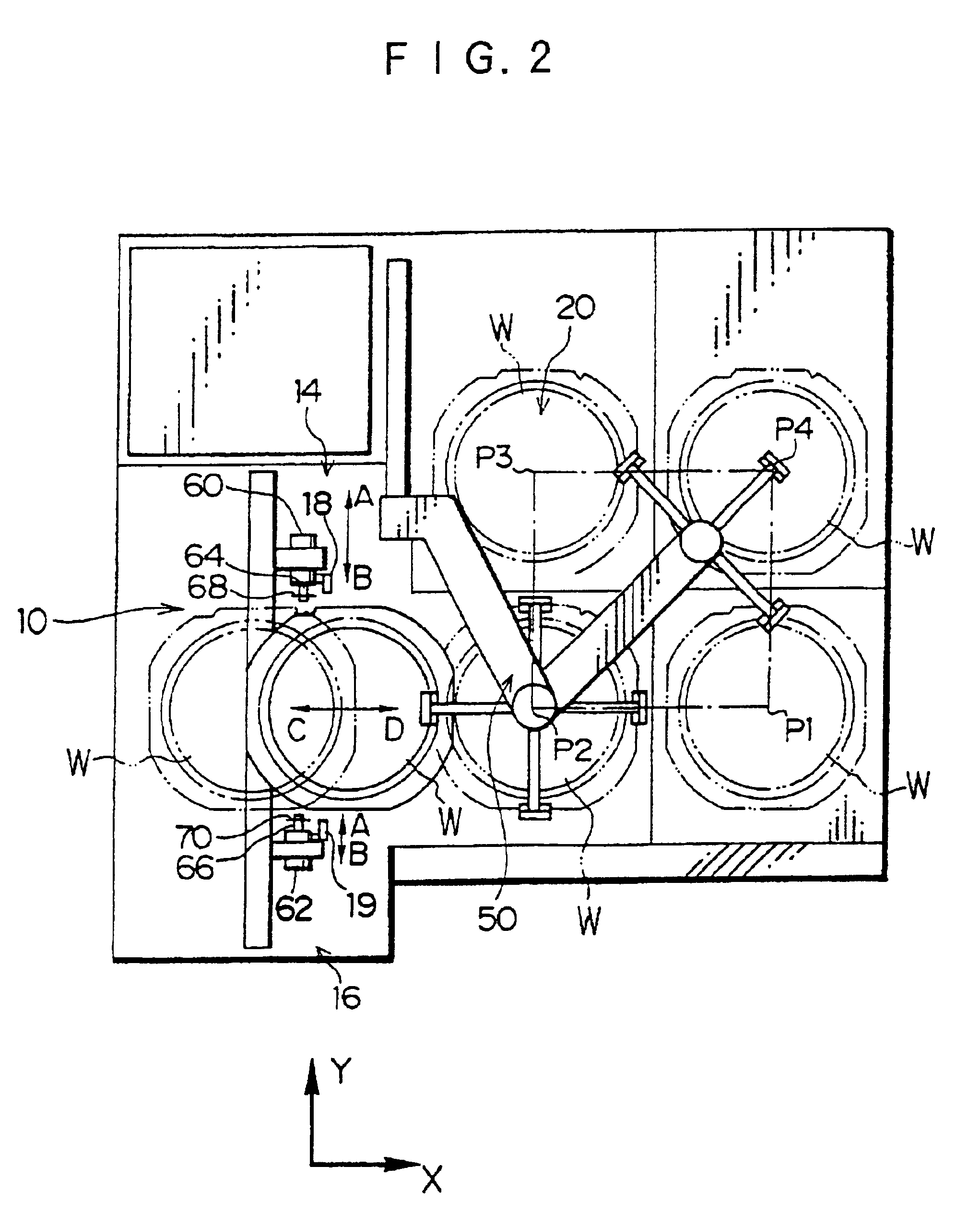

[0022]This invention will be described in further detail by way of example with reference to the accompanying drawings with reference to the accompanying drawings.

[0023]FIG. 1 is a perspective view of a dicing machine 1 for a semiconductor wafer according to the present invention, and FIG. 2 is a plan view of the dicing machine 1. As shown in FIG. 1, the dicing machine 1 is comprised mainly of a cutting part 10, a cleaning part 20, a cassette housing part 30, an elevator part 40 and transport equipment 50.

[0024]A description will be given of a cutting process of the dicing machine 1. First, a plurality of wafers W, which are housed in the cassette housing part 30, are sequentially retrieved by the elevator part 40, and the retrieved wafer W is set at a position P4 in FIG. 2. The wafer W is placed on a cutting table (position P2: see FIG. 4) 12 of the cutting part 10 via a pre-load stage at a position P1. The wafer W is vacuumed to the cutting table 12. Imaging equipment 18, 19 for a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Time | aaaaa | aaaaa |

| Speed | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com