Brush head positioning system

a positioning system and brush head technology, applied in the direction of photosensitive materials, carpet cleaners, instruments, etc., can solve the problems of uneven floor surface, operator's desire, brushes and pads can wear, etc., and achieve the effect of raising and lowering the support and low manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

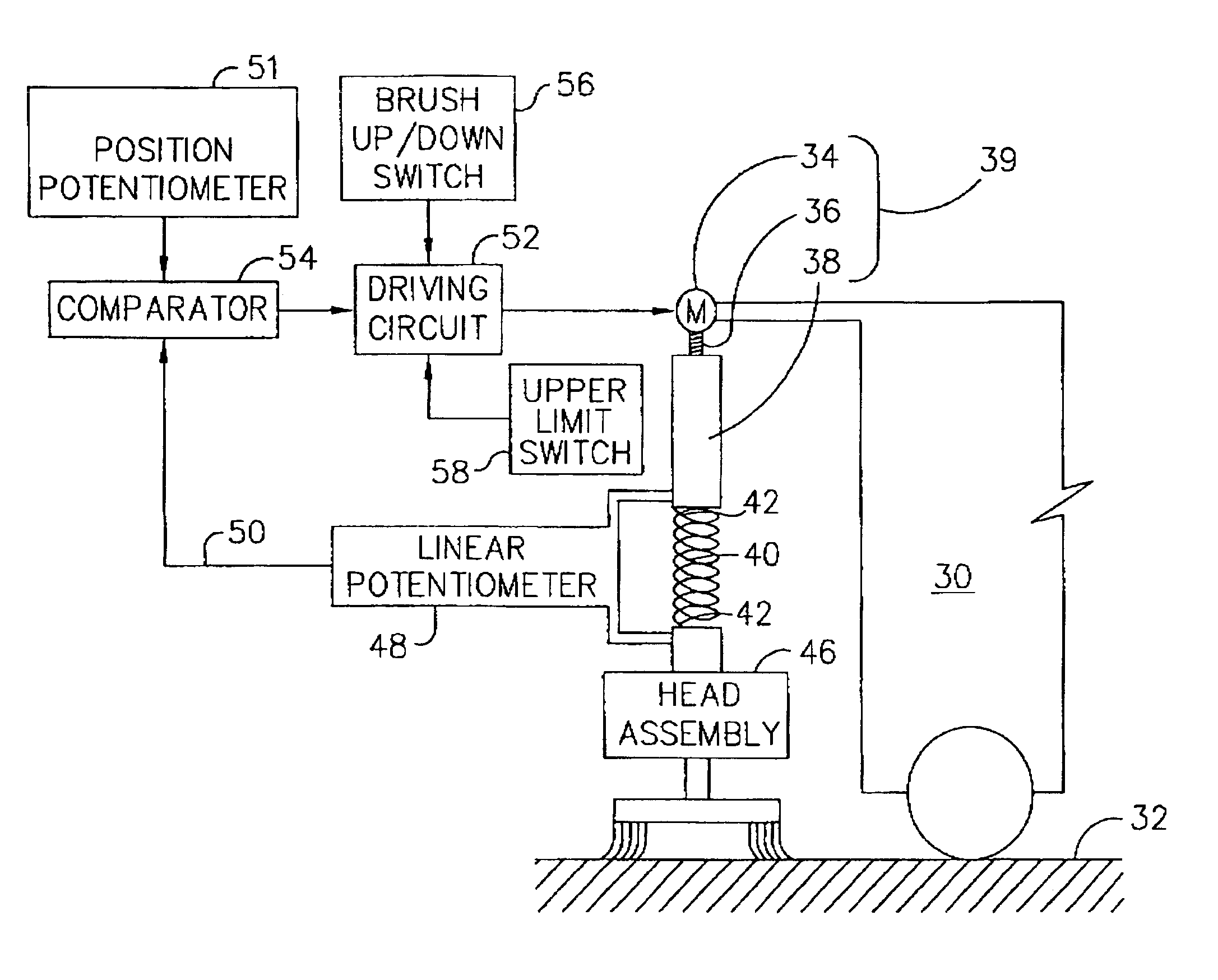

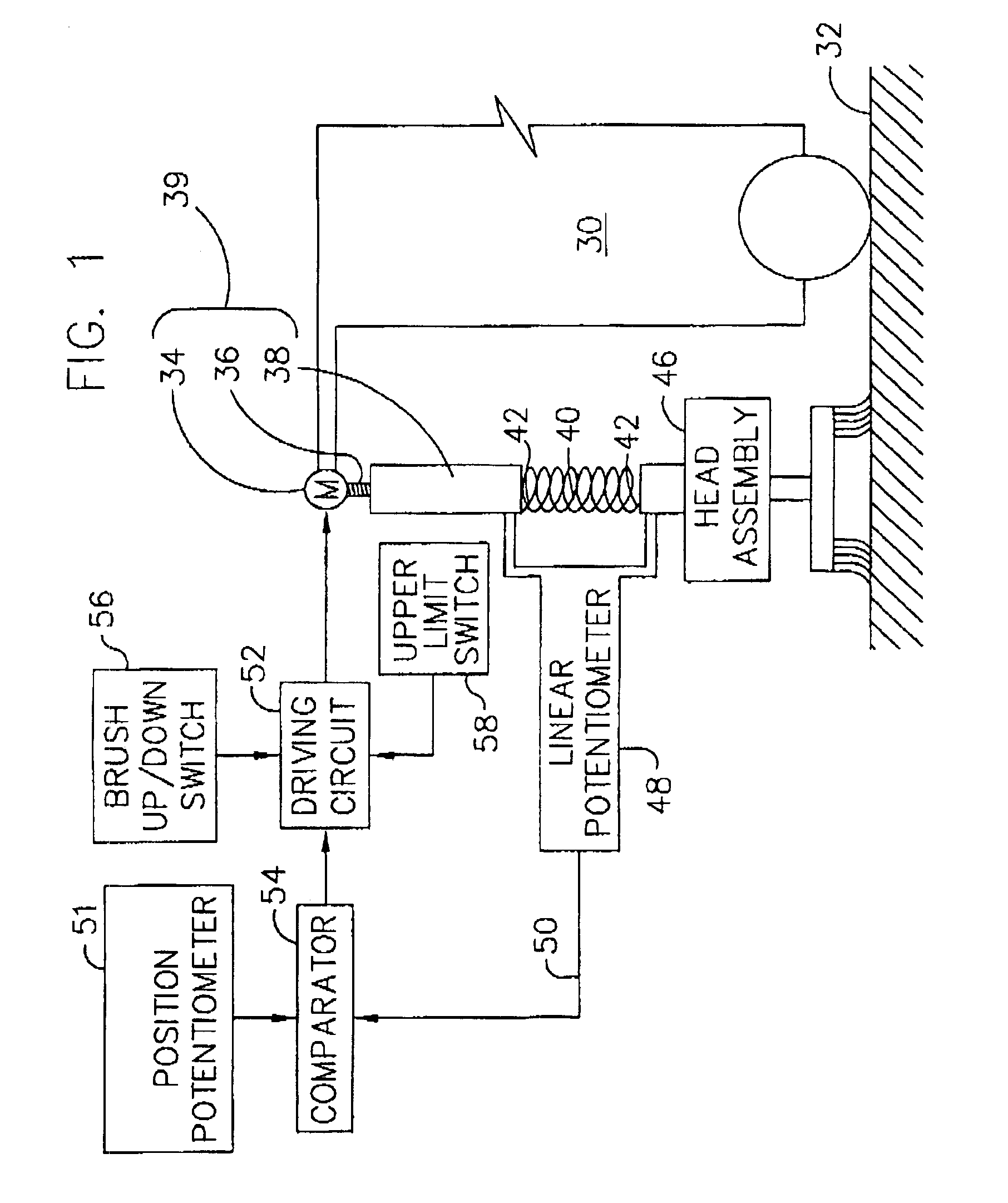

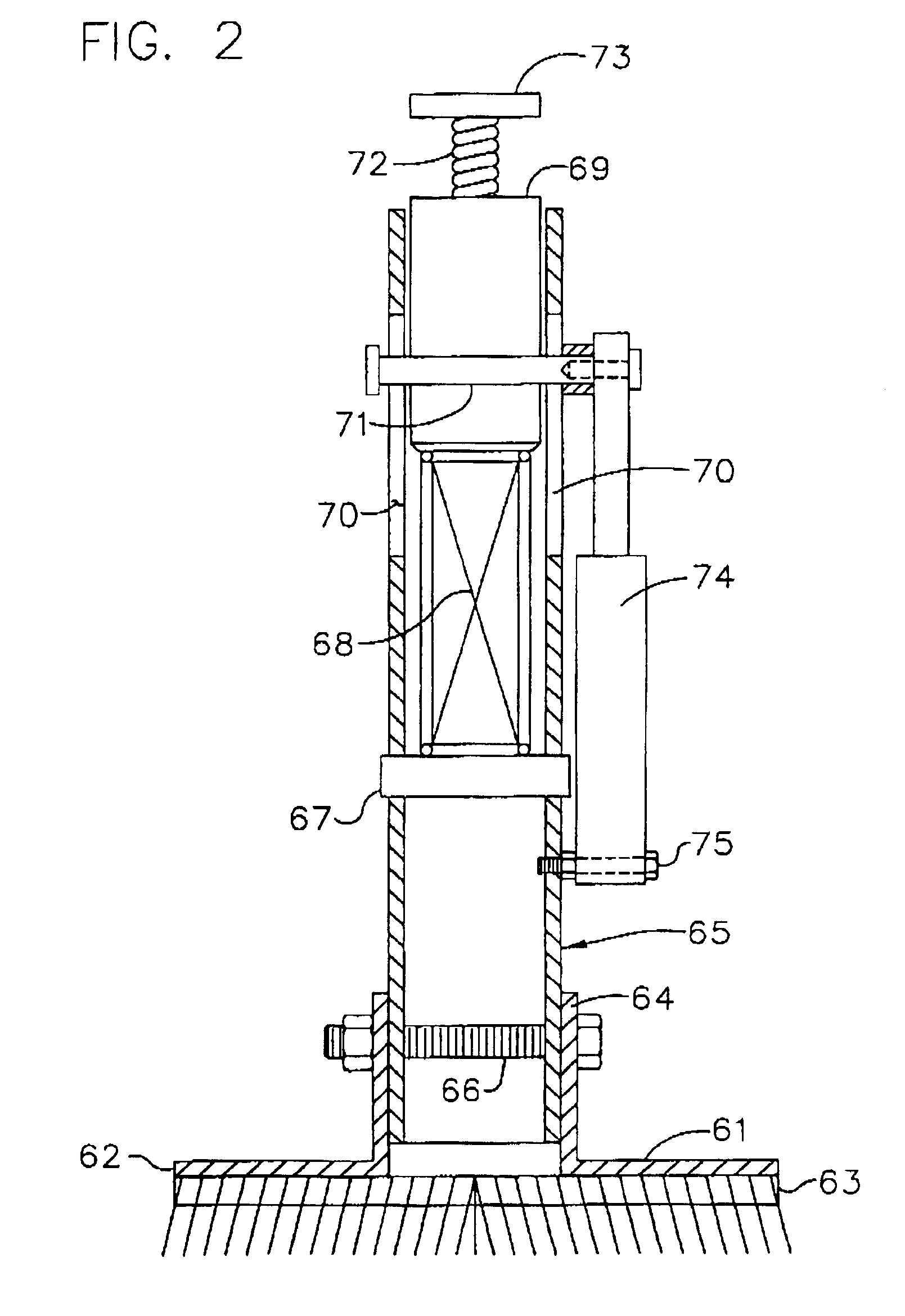

[0040]Referring to FIG. 1, a block diagram of one preferred embodiment of the system according to the invention is illustrated. A vehicle 30 which rests on and traverses a floor 32 (or other surface) supports a motor 34 for driving a screw 36. Rotation of the screw causes a support nut 38 to move upward or downward, depending on the rotation of the screw. A compressible member 40, such as a coil spring, has one end 42 connected to and engaging the nut 38 and has a second end 44 connected to and engaging a head assembly 46. The compressible member is positioned within a tube (not shown). The details of this interconnection between the compressible member 40, the actuator 39 and the head assembly 46 is shown in motor detail i FIGS. 2, 5 and 6 below.

[0041]A linear potentiometer 48 is positioned between the nut 38 and the head assembly 46 and generates a voltage signal via line 50 which indicates the distance between the nut 38 and head assembly 46. This generated signal also indicates ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com