Medicinal product with a textile component

a technology of textiles and medical products, applied in the field of medical products with textile components, can solve the problems of not promoting angiogenesis, and achieve the effect of increasing the anisotropy of the collagen network and the dimension of the collagen fibers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

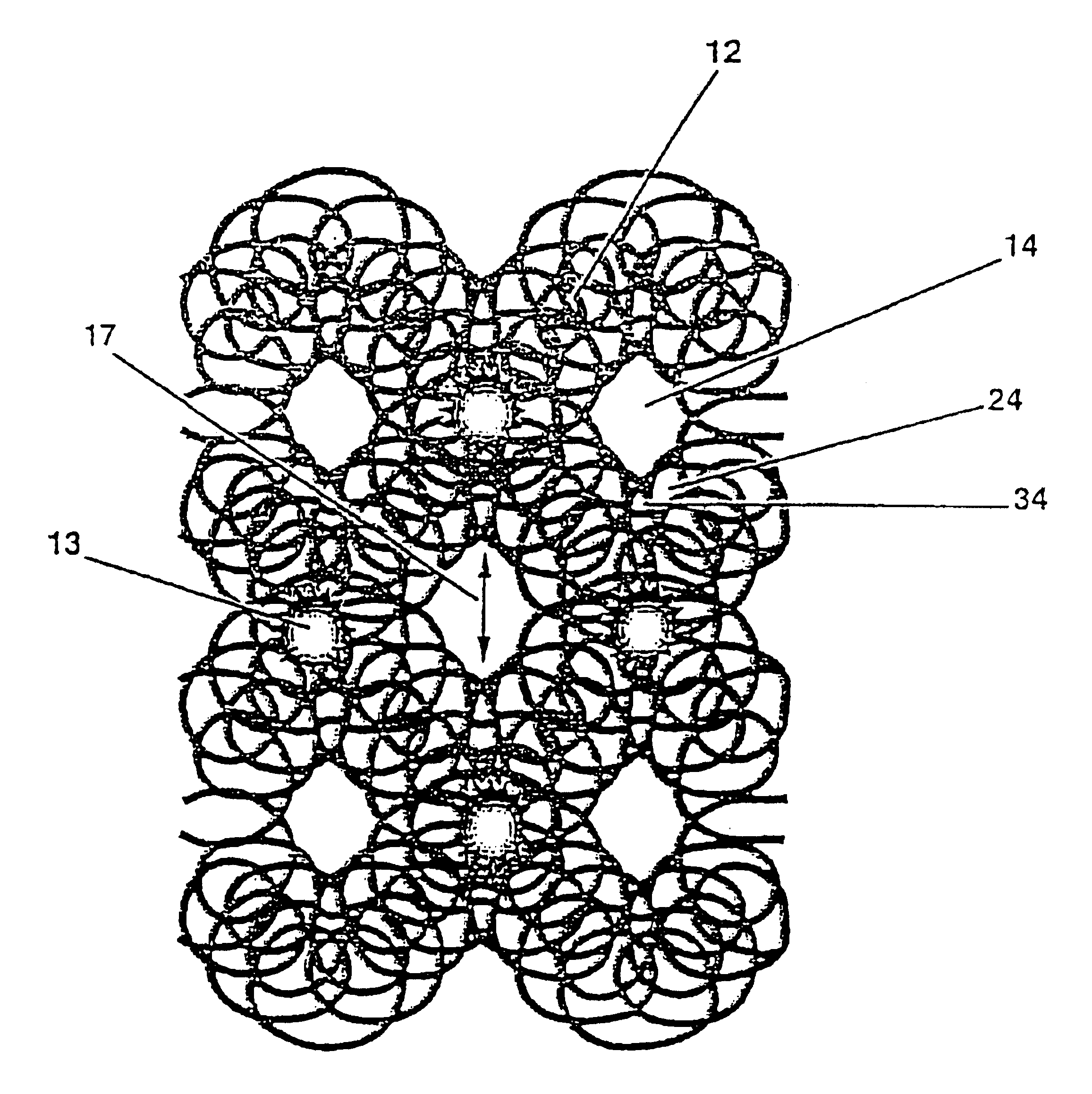

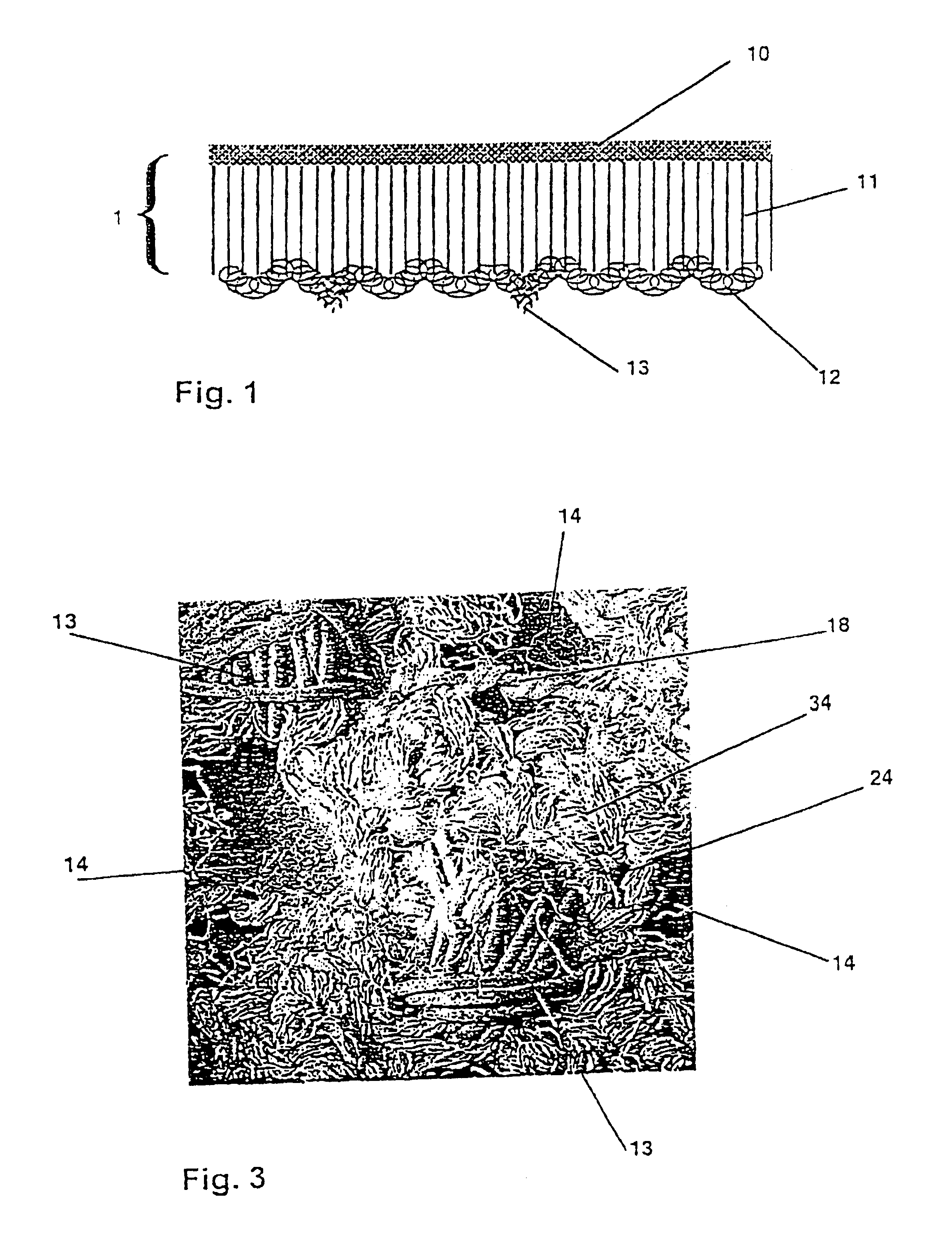

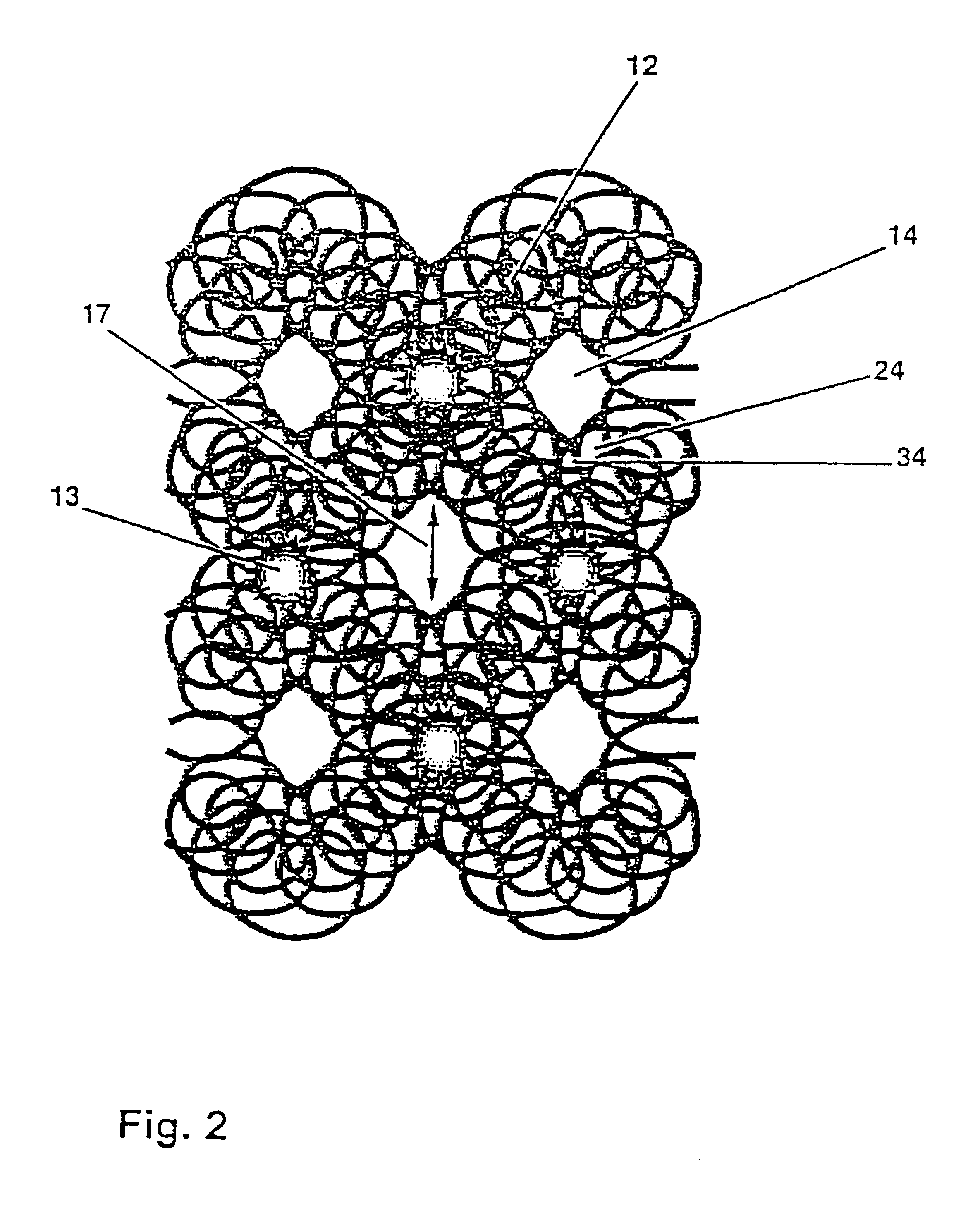

Embodiment Construction

[0028]A spacer layer 11 with high shear force takeup consisting of gel-modified yarns permits absorption and desorption and the mechanical binding of the compress material. The shear force takeup permits the distribution of local pressure loads, that is to say it has a cushion function and permits stress distribution, which leads to uniform loading of the wound surface and thus avoids negative local stresses. Lastly, the compress 1 has an embroidered layer 12. The fabric 11 is designed as a spacer in relation to the antibacterial layer 10 and as a material which takes up exudate. On this fabric 11, which is advantageously formed as a knit, lies the separately produced embroidered layer 12 which is preferably connected at its side edges to the compress 1, for example by ultrasonic welding. Reference number 13 denotes stimulation points which are formed in the layer 12, particularly in the embroidery technique. In the form represented, they form flat to semi-round protuberances, stimu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com