Patents

Literature

31results about How to "High and stable nitrogen yield" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Micro-alloy building steel bar containing V, Nb and Cr and LF production method of micro-alloy building steel bar

The invention belongs to the field of steel and iron metallurgy and particularly relates to a micro-alloy building steel bar containing V, Nb and Cr and an LF production method of the micro-alloy building steel bar to solve the problem that a selected vanadium nitride alloy for preparing nitrogen-containing alloy steel is low in nitrogen content and few in variety. The micro-alloy building steel bar comprises the components of, by weight, 0.15-0.30% of C, 0.30-1.00% of Si, 0.60-1.30% of Mn, 0.0060-0.0180% of N, 0.040% or the less of P, 0.040% or the less of S, 0.010-0.100% of V, 0.010-0.030% of Nb, 0.10-0.60% of Cr and the balance Fe and inevitable impurities. The key of the preparation method is that after refining in an LF, an N-containing core-spun yarn is fed, and N is adjusted to theappropriate level. According to the LF production method, operation is easy, the nitrogen yielding rate is high and stable, the production cost can further be effectively reduced, and thus the micro-alloy building steel bar and the LF production method are worthy of being used and popularized.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Ti-contained microalloy building steel bar and production method thereof

InactiveCN107964630AHigh strengthHigh Nitrogen YieldProcess efficiency improvementVanadium nitrideMetallurgy

The invention belongs to the field of steel metallurgy, in particular to a Ti-contained microalloy building steel bar and a production method of the Ti-contained microalloy building steel bar. The Ti-contained microalloy building steel bar and the production method of the Ti-contained microalloy building steel bar aim to solve the problems that in the prior art, the selected vanadium nitride alloyused for preparing nitrogen-contained alloy steel is low in nitrogen content, less in type and the like. The Ti-contained microalloy building steel bar comprises, by weight, 0.15%-0.30% of C, 0.30%-1.00% of Si, 0.60%-1.30% of Mn, 0.0060%-0.0180% of N, not larger than 0.040% of P, not larger than 0.040% of S, 0.010%-0.050% of Ti and the balance Fe and inevitable impurities. The key of the preparation method of the Ti-contained microalloy building steel bar is that N-contained core-spun wires are fed at a furnace rear small platform, and the content of N is adjusted to be the appropriate level.The production method of the Ti-contained microalloy building steel bar is easy to operate, the nitrogen yield is high and stable, the production cost can also be effectively reduced, and the Ti-contained microalloy building steel bar and the production method of the Ti-contained microalloy building steel bar are worthy of application and popularization.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Micro-alloy building steel bar containing Ti and Cr and production method of micro-alloy building steel bar

InactiveCN107747058AHigh strengthHigh Nitrogen YieldProcess efficiency improvementVanadium nitrideSteel bar

The invention belongs to the field of ferrous metallurgy, and particularly relates to a micro-alloy building steel bar containing Ti and Cr and a production method of the micro-alloy building steel bar. The micro-alloy building steel bar containing Ti and Cr and the production method of the micro-alloy building steel bar aim to solve the problems that the nitrogen content of an existing vanadium nitride alloy which is selected and used for preparing nitrogen-containing alloy steel is low, and the variety is small. The micro-alloy building steel bar comprises the compositions of, by weight, 0.15-0.30% of C, 0.30-1.00% of Si, 0.60-1.30% of Mn, 0.0060-0.0180% of N, less than or equal to 0.040% of P, less than or equal to 0.040% of S, 0.010-0.050% of Ti, 0.10-0.60% of Cr and the balance Fe andunavoidable impurities. The key point of the preparation method of the micro-alloy building steel bar lies in that a cored wire containing N is fed into a small platform behind a furnace, and the content of N is adjusted to be at an appropriate level. According to the production method of the micro-alloy building steel bar, operation is simple, the nitrogen yielding rate is high and stable, the production cost can further be effectively reduced, and the production method is worth being applied and popularized.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

V-containing micro-alloy building steel bar and LF production method thereof

The invention belongs to the field of iron and steel metallurgy and particularly relates to a V-containing micro-alloy building steel bar and an LF production method thereof. The V-containing micro-alloy building steel bar and the LF production method thereof are provided in order to solve the problems that a vanadium nitride alloy selected for preparing nitrogen-containing alloy steel in the prior art is low in nitrogen content, small in variety and the like. The V-containing micro-alloy building steel bar comprises the components of, by weight, 0.15%-0.30% of C, 0.30%-1.00% of Si, 0.60%-1.30% of Mn, 0.0060%-0.0180% of N, no more than 0.040% of P, no more than 0.040% of S, 0.010%-0.160% of V and the balance Fe and inevitable impurities. The key point of the preparation method of the V-containing micro-alloy building steel bar is that after LF refining, core-spun yarn is fed in a steel ladle for adjusting the N content to the appropriate level. The method is easy to operate, the nitrogen yield is high and stable, the production cost can be further reduced effectively, and thus the V-containing micro-alloy building steel bar is worth using and popularizing.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Nb-containing microalloy building steel wire rod and production method thereof

The invention belongs to the field of ferrous metallurgy and particularly relates to a Nb-containing microalloy building steel wire rod and a production method thereof. Specific to the problems of lownitrogen content and less variety of the vanadium nitride alloy selected in existing preparation of nitrogen-containing alloy steel, the invention provides a Nb-containing microalloy building steel wire rod and a production method thereof. The steel wire rod comprises the components in percent by weight: 0.15-0.30% of C, 0.30-1.00% of Si, 0.60-1.30% of Mn, 0.0060-0.0180% of N, smaller than or equal to 0.040% of P, smaller than or equal to 0.040% of S, 0.010-0.050% of Nb and the balance of Fe and inevitable impurities. The key of the preparation method is to feed N-containing core-coated wireson a small platform behind a furnace to adjust the N to a proper level. The production method is simple to operate, high in N yield and stable, can effectively reduce the production cost and is worthy of popularization.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

V-containing microalloy building steel bar and production method thereof

InactiveCN107974619AHigh strengthHigh Nitrogen YieldProcess efficiency improvementYarnVanadium nitride

The invention belongs to the field of iron and steel metallurgy, and particularly relates to a V-containing microalloy building steel bar and a production method thereof. According to the V-containingmicroalloy building steel bar and the production method thereof, the problems that a vanadium nitride alloy selected by an existing prepared nitrogen-containing alloy steel is low in nitrogen content, few in kind and the like are solved. The bar comprises the compositions of, by weight, 0.15-0.30% of C, 0.30-1.00% of Si, 0.60-1.30% of Mn, 0.0060-0.0180% of N, no more than 0.040% of P, no more than 0.040% of S, 0.010-0.160% of V, and the balance Fe and unavoidable impurities. The preparation method is characterized in that N-containing core-spun yarn is fed into an after-furnace small platform, and N is adjusted to the appropriate level. The method is simple in operation, the nitrogen recovery rate is high, and stability is achieved; and the production cost can further be effectively reduced, and the method is worth using and popularizing.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Microalloy building steel bar containing V and Ti and production method thereof

The invention belongs to the field of iron and steel metallurgy and particularly relates to a microalloy building steel bar containing V and Ti and a production method thereof. The microalloy buildingsteel bar containing V and Ti and the production method thereof are provided aiming at the problems of low nitrogen content, few types and the like of a vanadium nitride alloy which is adopted for preparing nitrogen-containing alloy steel in the prior art. The microalloy building steel bar comprises the components of, by weight, 0.15%-0.30% of C, 0.30%-1.00% of Si, 0.60%-1.30% of Mn, 0.0060%-0.0180% of N, no more than 0.040% of P, no more than 0.040% of S, 0.010%-0.100% of V, 0.010%-0.030% of Ti and the balance Fe and inevitable impurities. The key step of the preparation method of the microalloy building steel bar containing V and Ti is that N-containing cored wires are fed in a small platform behind a furnace, and the N content is adjusted to the appropriate level. The production methodis easy to operate, the nitrogen yield is high and stable, the production cost can be further reduced effectively, and thus the production method is worth applying and popularizing.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Nb-containing micro-alloy constructional steel bar and LF (Low-Frequency) furnace production method thereof

The invention belongs to the field of steel and iron metallurgy and particularly relates to an Nb-containing micro-alloy constructional steel bar and an LF furnace production method thereof. Aiming atthe problems about low nitrogen content and few types of vanadium nitride used by an existing method for preparing nitrogen-containing alloy steel, the invention provides the Nb-containing micro-alloy constructional steel bar and the LF furnace production method thereof. The bar comprises the following components in percentage by weight: 0.15 to 0.30 percent of C, 0.30 to 1.00 percent of Si, 0.60to 1.30 percent of Mn, 0.0060 to 0.0180 percent of N, smaller than or equal to 0.040 percent of P, smaller than or equal to 0.040 percent of S, 0.010 to 0.050 percent of Nb and the balance of Fe andinevitable impurities. The key points of a preparation method of the Nb-containing micro-alloy constructional steel bar are that an N-containing core-spun yarn is fed into the LF furnace after refining is ended, and the content of N is regulated to a suitable level. The method provided by the invention is simple to operate, high and stable in nitrogen yield, also capable of effectively lowering the production cost and worthy of popularization and application.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Ti-containing microalloy constructional steel bar material and LF furnace production method thereof

The invention belongs to the field of steel metallurgy and particularly relates to a Ti-containing microalloy constructional steel bar material and a LF furnace production method thereof. The Ti-containing microalloy constructional steel bar material and the LF furnace production method thereof aim at solving the problems that at present, vanadium nitride alloys selected for producing nitrogen-containing alloy steel are low in nitrogen content, small in number of varieties and the like. The bar material comprises, by weight percentage, 0.15-0.30% of C, 0.30-1.00% of Si, 0.60-1.30% of Mn, 0.0060-0.0180% of N, less than or equal to 0.040% of P, less than or equal to 0.040% of S, 0.010-0.050% of Ti and the balance Fe and inevitable impurities. According to the production method of the Ti-containing microalloy constructional steel bar material, the key point lies in that a N-containing core-spun yarn is fed into a LF furnace after refining is completed, and the N content is adjusted to theproper level. The method is easy to operate, high in nitrogen yield, stable, capable of effectively lowering production cost and worthy of being applied and popularized.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

V and Nb-contained microalloy construction steel rod and LF furnace preparation method thereof

The invention belongs to the field of steel and iron metallurgy, and in particular, relates to a V and Nb-contained microalloy construction steel rod and a LF furnace preparation method thereof. Aiming at the problems of low nitrogen content and few types of vanadium nitride alloys selected for traditional preparation of nitrogen-contained alloy steel, the invention provides the V and Nb-containedmicroalloy construction steel rod and the LF furnace preparation method thereof. The rod comprises the following components in percentage by weight: 0.15-0.30% of C, 0.30-1.00% of Si, 0.60-1.30% of Mn, 0.0060-0.0180% of N, P not more than 0.040%, S not more than 0.040%, 0.010-0.100% of V, 0.010-0.030% of Nb, and the balance of Fe and inevitable impurities. The preparation method is characterizedin that N-contained core-spun yarns are fed after refining in a LF furnace and N is adjusted to a proper level. The method is simple in operation; the nitrogen yield is high and stable; the productioncost can be effectively reduced; and the method deserves popularization and application.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

V, Nb and Cr contained microalloy building steel wire rod and LF production method thereof

The invention belongs to the field of ferrous metallurgy, and particularly relates to a V, Nb and Cr contained microalloy building steel wire rod and an LF production method thereof. In order to solvethe problems that an existing vanadium nitride alloy for preparing nitrogen containing alloyed steel is low in nitrogen content and little in kind, the invention provides the V, Nb and Cr contained microalloy building steel wire rod and the LF production method therefore. The steel wire rod comprises, by weight percent, 0.15 to 0.30% of C, 0.30 to 1.00% of Si, 0.60 to 1.30% of Mn, 0.0060 to 0.0180% of N, not larger than 0.040% of P, not larger than 0.040% of S, 0.010 to 0.100% of V, 0.010 to 0.030% of Nb, 0.10 to 0.60% of Cr and the balance Fe and inevitable impurities. The preparing method is characterized in that an N contained cored wire is fed into an LF, and the N is adjusted to the proper level. The method is easy to operate, the nitrogen yield is high and stable, production cost can be effectively reduced, and the steel wire rod is worth of use and popularization.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

V and Cr containing microalloy building steel wire rod and production method thereof

The invention belongs to the field of ferrous metallurgy, and particularly relates to a V and Cr containing microalloy building steel wire rod and a production method thereof. The V and Cr containingmicroalloy building steel wire rod and the production method thereof are provided according to the problems that vanadium nitride alloys selected for preparing nitrogen containing alloy steel in the prior art are low in nitrogen content, few in kind and the like. The steel wire rod comprises, by weight percent, 0.15%-0.30% of C, 0.30%-1.00% of Si, 0.60%-1.30% of Mn, 0.0060%-0.0180% of N, not larger than 0.040% of P, not larger than 0.040% of S, 0.010%-0.160% of V, 0.10%-0.60% of Cr and the balance Fe and inevitable impurities. The preparation method of the steel wire rod is characterized in that an N containing cored wire is fed into a furnace rear small platform, and N is adjusted to the proper level. The method is simple in operation, the nitrogen yield is high and stable, the productioncost can be effectively reduced, and the method is worthy of use and popularization.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Building steel bar containing V, Ti and Cr microalloys as well as LF (ladle furnace) production method of building steel bar

The invention belongs to the field of iron and steel metallurgy, and particularly relates to a building steel bar containing V, Ti and Cr microalloys as well as an LF (ladle furnace) production methodof the building steel bar. In order to solve the problems that vanadium nitride alloys selected for the preparation of nitrogen alloy steel are low in nitrogen content, and the types of the vanadiumnitride alloys are less, the building steel bar and the LF production method are provided. The building steel bar comprises the following components in percentage by weight: 0.15-0.30% of C, 0.30-1.00% of Si, 0.60-1.30% of Mn, 0.0060-0.0180% of N, not more than 0.040% of P, not more than 0.040% of S, 0.010-0.100% of V, 0.010-0.030% of Ti, 0.10-060% of Cr, and the balance Fe and inevitable impurities. The key of a method for preparing the building steel bar is to feed a nitrogen-containing cored wire into a steel ladle after LF refining so as to adjust the nitrogen content to an appropriate level; the LF production method is simple to operate; the nitrogen yield is high and stable; furthermore, the production cost can be effectively reduced; and the building steel bar and the LF productionmethod are worthy of popularization and utilization.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

V, Nb and Ti-contained microalloy construction steel rod and preparation method thereof

The invention belongs to the field of steel and iron metallurgy, and in particular, relates to a V, Nb and Ti-contained microalloy construction steel rod and a preparation method thereof. Aiming at the problems of low nitrogen content and few types of vanadium nitride alloys selected for traditional preparation of nitrogen-contained alloy steel, the invention provides the V, Nb and Ti-contained microalloy construction steel rod and the preparation method thereof. The rod comprises the following components in percentage by weight: 0.15-0.30% of C, 0.30-1.00% of Si, 0.60-1.30% of Mn, 0.0060-0.0180% of N, P not more than 0.040%, S not more than 0.040%, 0.010-0.080% of V, 0.010-0.030% of Nb, 0.010-0.030% of Ti, and the balance of Fe and inevitable impurities. The preparation method is characterized in that N-contained core-spun yarns are fed in a small platform after a furnace and N is adjusted to a proper level. The method is simple in operation; the nitrogen yield is high and stable; theproduction cost can be effectively reduced; and the method deserves popularization and application.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Ti and Cr contained microalloy building steel wire rod and LF production method thereof

The invention belongs to the field of ferrous metallurgy, and particularly relates to a Ti and Cr contained microalloy building steel wire rod and an LF production method thereof. In order to solve the problems that an existing vanadium nitride alloy for preparing nitrogen containing alloyed steel is low in nitrogen content and little in kind, the invention provides the Ti and Cr contained microalloy building steel wire rod and the LF production method therefore. The steel wire rod comprises, by weight percent, 0.15 to 0.30% of C, 0.30 to 1.00% of Si, 0.60 to 1.30% of Mn, 0.0060 to 0.0180% ofN, not larger than 0.040% of P, not larger than 0.040% of S, 0.010 to 0.050% of Ti, 0.10 to 0.60% of Cr and the balance Fe and inevitable impurities. The preparing method is characterized in that an Ncontained cored wire is fed into an LF, and the N is adjusted to the proper level. The method is easy to operate, the nitrogen yield is high and stable, production cost can be effectively reduced, and the steel wire rod is worth of use and popularization.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Microalloy constructional steel coil rod containing V, Nb and Ti and LF furnace production method of microalloy constructional steel coil rod

The invention belongs to the field of steel metallurgy and particularly relates to a microalloy constructional steel coil rod containing V, Nb and Ti and an LF furnace production method of the microalloy constructional steel coil rod. The microalloy constructional steel coil rod containing V, Nb and Ti and the LF furnace production method of the microalloy constructional steel coil rod aim at solving the problems that at present, vanadium nitride alloys selected for producing nitrogen-containing alloy steel are low in nitrogen content, small in number of varieties and the like. The coil rod comprises, by weight percentage, 0.15-0.30% of C, 0.30-1.00% of Si, 0.60-1.30% of Mn, 0.0060-0.0180% of N, less than or equal to 0.040% of P, less than or equal to 0.040% of S, 0.010-0.080% of V, 0.010-0.030% of Nb, 0.010-0.030% of Ti and the balance Fe and inevitable impurities. According to the production method of the microalloy constructional steel coil rod, the key point lies in that a N-containing core-spun yarn is fed into a LF furnace, and the N content is adjusted to the proper level. The method is easy to operate, high in nitrogen yield, stable, capable of effectively lowering production cost and worthy of being applied and popularized.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

V and Cr-contained microalloy construction steel rod and preparation method thereof

The invention belongs to the field of steel and iron metallurgy, and in particular, relates to a V and Cr-contained microalloy construction steel rod and a preparation method thereof. Aiming at the problems of low nitrogen content and few types of vanadium nitride alloys selected for traditional preparation of nitrogen-contained alloy steel, the invention provides the V and Cr-contained microalloyconstruction steel rod and the preparation method thereof. The rod comprises the following components in percentage by weight: 0.15-0.30% of C, 0.30-1.00% of Si, 0.60-1.30% of Mn, 0.0060-0.0180% of N, P not more than 0.040%, S not more than 0.040%, 0.010-0.160% of V, 0.10-0.60% of Cr, and the balance of Fe and inevitable impurities. The preparation method is characterized in that N-contained core-spun yarns are fed in a small platform after a furnace and N is adjusted to a proper level. The method is simple in operation; the nitrogen yield is high and stable; the production cost can be effectively reduced; and the method deserves popularization and application.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Microalloy building steel wire rod containing V, Ti and Cr and production method of microalloy building steel wire rod

The invention belongs to the field of steel metallurgy and particularly relates to a microalloy building steel wire rod containing V, Ti and Cr and a production method of the microalloy building steelwire rod. The microalloy building steel wire rod containing V, Ti and Cr and the production method of the microalloy building steel wire rod are provided for solving the problems that vanadium nitride alloys are adopted for preparing nitrogen-containing alloy steel at present, the nitrogen content is low, and kinds are few. The steel wire rod includes, by weight, 0.15%-0.30% of C, 0.30%-1.00% ofSi, 0.60%-1.30% of Mn, 0.0060%-0.0180% of N, smaller than or equal to 0.040% of P, smaller than or equal to 0.040% of S, 0.010%-0.100% of V, 0.010%-0.030% of Ti, 0.10%-0.60% of Cr and the balance Fe and inevitable impurities. The preparing method of the microalloy building steel wire rod containing V, Ti and Cr is characterized in that N-containing core spun yarn is fed into a small platform behind a furnace, and N is adjusted to the proper level. The method is easy to operate, the nitrogen yield is high and stable, the production cost can also be effectively reduced, and the method is worthyof application and popularization.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Microalloy building steel wire rod containing V, Nb, Ti and Cr and production method of microalloy building steel wire rod

The invention belongs to the field of steel metallurgy and particularly relates to a microalloy building steel wire rod containing V, Nb, Ti and Cr and a production method of the microalloy building steel wire rod. The microalloy building steel wire rod containing V, Nb, Ti and Cr and the production method of the microalloy building steel wire rod are provided for solving the problems that vanadium nitride alloys are adopted for preparing nitrogen-containing alloy steel at present, the nitrogen content is low, and kinds are few. The steel wire rod includes, by weight, 0.15%-0.30% of C, 0.30%-1.00% of Si, 0.60%-1.30% of Mn, 0.0060%-0.0180% of N, smaller than or equal to 0.040% of P, smaller than or equal to 0.040% of S, 0.010%-0.080% of V, 0.010%-0.030% of Nb, 0.010%-0.030% of Ti, 0.10%-0.60% of Cr and the balance Fe and inevitable impurities. The preparing method of the microalloy building steel wire rod containing V, Nb, Ti and Cr is characterized in that N-containing core spun yarn is fed into a small platform behind a furnace, and N is adjusted to the proper level. The method is easy to operate, the nitrogen yield is high and stable, the production cost can also be effectively reduced, and the method is worthy of application and popularization.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

V and Cr-contained microalloy construction steel rod and LF furnace preparation method thereof

The invention belongs to the field of steel and iron metallurgy, and in particular, relates to a V and Cr-contained microalloy construction steel rod and a LF furnace preparation method thereof. Aiming at the problems of low nitrogen content and few types of vanadium nitride alloys selected for traditional preparation of nitrogen-contained alloy steel, the invention provides the V and Cr-containedmicroalloy construction steel rod and the LF furnace preparation method thereof. The rod comprises the following components in percentage by weight: 0.15-0.30% of C, 0.30-1.00% of Si, 0.60-1.30% of Mn, 0.0060-0.0180% of N, P not more than 0.040%, S not more than 0.040%, 0.010-0.160% of V, 0.10-0.60% of Cr, and the balance of Fe and inevitable impurities. The preparation method is characterized inthat N-contained core-spun yarns are fed after refining in a LF furnace and N is adjusted to a proper level. The method is simple in operation; the nitrogen yield is high and stable; the production cost can be effectively reduced; and the method deserves popularization and application.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Microalloyed building steel wire rod containing V and production method thereof

The invention belongs to the field of iron and steel metallurgy, and particularly relates to a microalloyed building steel wire rod containing V and a production method thereof. The microalloyed building steel wire rod containing V and the production method of the microalloyed building steel wire rod aim to solve the problems that the nitrogen content of an existing vanadium nitride alloy which isselected and used for preparing nitrogen-containing alloy steel is low, and the variety is small. The composition of the steel wire rod comprises, by weight, 0.15-0.30% of C, 0.30-1.00% of Si, 0.60-1.30% of Mn, 0.0060-0.0180% of N, no more than 0.040% of P, no more than 0.040% of S, 0.010-0.160% of V and the balance being Fe and unavoidable impurities. The key point of the preparation method of the microalloyed building steel wire rod lies in that a cored wire containing N is fed into a small platform behind a furnace, and the content of N is adjusted to be at an appropriate level. Accordingto the production method of the microalloyed building steel wire rod, operation is simple, the nitrogen yielding rate is high and stable, the production cost can further be effectively reduced, and the production method is worth being applied and popularized.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Micro-alloy building steel bar containing V, Nb, Ti and Cr and LF production method of micro-alloy building steel bar

The invention belongs to the field of steel and iron metallurgy and particularly relates to a micro-alloy building steel bar containing V, Nb, Ti and Cr and an LF production method of the micro-alloybuilding steel bar to solve the problem that a selected vanadium nitride alloy for preparing nitrogen-containing alloy steel is low in nitrogen content and few in variety. The micro-alloy building steel bar comprises the components of, by weight, 0.15-0.30% of C, 0.30-1.00% of Si, 0.60-1.30% of Mn, 0.0060-0.0180% of N, 0.040% or the less of P, 0.040% or the less of S, 0.010-0.080% of V, 0.010-0.030% of Nb, 0.010-0.030% of Ti, 0.10-0.60% of Cr and the balance Fe and inevitable impurities. The key of the preparation method is that after refining in an LF, an N-containing core-spun yarn is fed, and N is adjusted to the appropriate level. According to the LF production method, operation is easy, the nitrogen yielding rate is high and stable, the production cost can further be effectively reduced, and thus the micro-alloy building steel bar and the LF production method are worthy of being used and popularized.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Construction steel wire rod containing Ti microalloy and a ladle furnace (LF) production method thereof

InactiveCN107955916AHigh strengthImprove performanceProcess efficiency improvementWire rodVanadium nitride

The invention belongs to the field of ferrous metallurgy, and particularly relates to a construction steel wire rod containing Ti microalloy and a ladle furnace (LF) production method thereof. Aimingat solving the problems that vanadium nitride adopted for preparing nitrogen-contained alloy steel in the prior art is low in nitrogen content and small in variety, the invention provides the construction steel wire rod containing the Ti microalloy and the LF production method thereof. The steel wire rod comprises, by weight, 0.15-0.30% of C, 0.30-1.00% of Si, 0.60-1.30% of Mn, 0.0060-0.0180% of N, 0-0.040% of P, 0-0.040% of S, 0.010-0.050% of Ti, and the balance Fe and inevitable impurities. The preparation method is characterized in that N-contained core-spun wires are fed after LF refining,and N is adjusted to the proper level. The method is easy to implement, the nitrogen yield is high and stable, the production cost can be effectively reduced, and the method is worthy of applicationand popularization.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Ti and Cr contained microalloy construction steel wire rod and production method thereof

The invention belongs to the field of steel and iron metallurgy, and in particular, relates to a Ti and Cr contained microalloy construction steel wire rod and a production method thereof. Aiming at the problems of low nitrogen content and few types of vanadium nitride alloys selected by traditional nitrogen-contained alloy steel, the invention provides the Ti and Cr contained microalloy construction steel wire rod and the production method thereof. The wire rod comprises the following components in percentage by weight: 0.15-0.30% of C, 0.30-1.00% of Si, 0.60-1.30% of Mn, 0.0060-0.0180% of N,P not more than 0.040%, S not more than 0.040%, 0.010-0.050% of Ti, 0.10-0.60% of Cr, and the balance of Fe and inevitable impurities. The key point of the preparation method is that N-contained corespun yarns are fed in a small platform after a furnace; and N is adjusted to a proper level. The method is simple in operation, is high and stable in nitrogen yield, can effectively reduce the production cost, and deserves popularization and application.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

V, Nb, Ti and Cr-contained microalloy construction steel rod and preparation method thereof

The invention belongs to the field of steel and iron metallurgy, and in particular, relates to a V, Nb, Ti and Cr-contained microalloy construction steel rod and a preparation method thereof. Aiming at the problems of low nitrogen content and few types of vanadium nitride alloys selected for traditional preparation of nitrogen-contained alloy steel, the invention provides the V, Nb, Ti and Cr-contained microalloy construction steel rod and the preparation method thereof. The rod comprises the following components in percentage by weight: 0.15-0.30% of C, 0.30-1.00% of Si, 0.60-1.30% of Mn, 0.0060-0.0180% of N, P not more than 0.040%, S not more than 0.040%, 0.010-0.080% of V, 0.010-0.030% of Nb, 0.010-0.030% of Ti, 0.10-0.60% of Cr, and the balance of Fe and inevitable impurities. The preparation method is characterized in that N-contained core-spun yarns are fed in a small platform after a furnace and N is adjusted to a proper level. The method is simple in operation; the nitrogen yield is high and stable; the production cost can be effectively reduced; and the method deserves popularization and application.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

V-containing microalloy building steel wire rod and LF furnace production method thereof

The invention belongs to the field of steel metallurgy and particularly relates to a V-containing microalloy building steel wire rod and an LF furnace production method of the V-containing microalloybuilding steel wire rod. The V-containing microalloy building steel wire rod and the LF furnace production method of the V-containing microalloy building steel wire rod are provided for solving the problems that vanadium nitride alloys are adopted for preparing nitrogen-containing alloy steel at present, the nitrogen content is low, and kinds are few. The steel wire rod includes, by weight, 0.15%-0.30% of C, 0.30%-1.00% of Si, 0.60%-1.30% of Mn, 0.0060%-0.0180% of N, smaller than or equal to 0.040% of P, smaller than or equal to 0.040% of S, 0.010%-0.160% of V and the balance Fe and inevitableimpurities. The preparing method of the V-containing microalloy building steel wire rod is characterized in that N-containing core spun yarn is fed into a LF furnace, and N is adjusted to the properlevel. The method is easy to operate, the nitrogen yield is high and stable, the production cost can also be effectively reduced, and the method is worthy of application and popularization.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Micro-alloy building steel bar containing V, Nb and Cr and production method of micro-alloy building steel bar

The invention belongs to the field of steel and iron metallurgy and particularly relates to a micro-alloy building steel bar containing V, Nb and Cr and a production method of the micro-alloy buildingsteel bar to solve the problem that a selected vanadium nitride alloy for preparing nitrogen-containing alloy steel is low in nitrogen content and few in variety. The micro-alloy building steel bar comprises the components of, by weight, 0.15-0.30% of C, 0.30-1.00% of Si, 0.60-1.30% of Mn, 0.0060-0.0180% of N, 0.040% or the less of P, 0.040% or the less of S, 0.010-0.100% of V, 0.010-0.030% of Nb, 0.10-0.60% of Cr and the balance Fe and inevitable impurities. The key of the preparation method is that an N-containing core-spun yarn is fed on a small platform behind a furnace, and N is adjustedto the appropriate level. According to the production method, operation is easy, the nitrogen yielding rate is high and stable, the production cost can further be effectively reduced, and thus the micro-alloy building steel bar and the LF production method are worthy of being used and popularized.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

V and Ti containing micro-alloyed building steel wire rod and production method thereof

The invention belongs to the field of ferrous metallurgy, in particular to a V and Ti containing micro-alloyed building steel wire rod and a production method thereof. In order to solve the problems such as low nitrogen content and fewer types of a vanadium nitride alloy for preparing nitrogen-containing alloy steel, the invention provides the V and Ti containing micro-alloyed building steel wirerod and the production method thereof. The wire rod consists of the following components in percentage by weight: 0.15-0.30% of C, 0.30-1.00% of Si, 0.60-1.30% of Mn, 0.0060-0.0180% of N, less than orequal to 0.040% of P, less than or equal to 0.040% of S, 0.010-0.100% of V, 0.010%-0.030% of Ti and the balance of Fe and inevitable impurities. The key point of the production method is that an N-containing core-spun yarn is fed into a small platform behind a furnace to regulate N to proper level. The production method is simple to operate, is high and stable in nitrogen yield, further can effectively reduce the production cost, and is worthy of being popularized and used.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Containing nb, cr microalloy construction steel wire rod and its lf furnace production method

The invention belongs to the field of ferrous metallurgy, and particularly relates to an Nb and Cr containing microalloy building steel wire rod and an LF furnace production method thereof. The Nb andCr containing microalloy building steel wire rod and the LF furnace production method thereof are provided according to the problems that vanadium nitride alloys selected for preparing nitrogen containing alloy steel in the prior art are low in nitrogen content, few in kind and the like. The steel wire rod comprises, by weight percent, 0.15%-0.30% of C, 0.30%-1.00% of Si, 0.60%-1.30% of Mn, 0.0060%-0.0180% of N, not larger than 0.040% of P, not larger than 0.040% of S, 0.010%-0.050% of Nb, 0.10%-0.60% of Cr and the balance Fe and inevitable impurities. The preparation method of the steel wirerod is characterized in that an N containing cored wire is fed into an LF furnace, and N is adjusted to the proper level. The method is simple in operation, the nitrogen yield is high and stable, theproduction cost can be effectively reduced, and the method is worthy of use and popularization.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

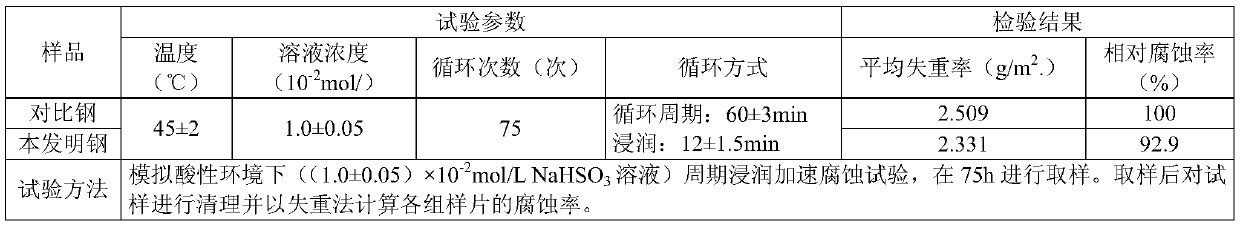

A kind of stainless steel material and its manufacturing method

ActiveCN103374685BNo allergiesHigh strengthElectric furnaceMilling equipment detailsSolid nitrogenAustenite

Disclosed is a stainless steel material and a manufacturing method therefor. The stainless steel material is a Cr-Mn-N austenitic stainless steel where nickel is replaced by nitrogen. The manufacturing method comprises: a smelting method, a blank stamping method and a machining method. The smelting method mainly consists in the smelting of high nitrogen steel by means of two methods of a solid nitrogen-containing material and gaseous nitrogen for alloying and increasing a nitrogen content. The blank stamping method mainly consists in repeated cycles of blank stamping, thermal treatment, solid solution treatment; the control of heat-preserving temperature and duration, and the selection of moulds mainly takes the hardness and impact toughness values into consideration. The machining mainly comprises the control of the suitable processing parameters for milling and turning operations. The smelting method for the stainless steel material is suitable for the batchwise smelting of high nitrogen steel having a nitrogen content of 0.4 wt%-0.75 wt%; the blank stamping method inhibits the cold-work hardening phenomenon during the processing of high nitrogen steels, and facilitates the stamping of the blank; and the machining method overcomes the problem of high processing difficulty due to the great hardness of high nitrogen steel.

Owner:CENT IRON & STEEL RES INST +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com