Ti and Cr contained microalloy building steel wire rod and LF production method thereof

A production method and microalloying technology, applied in the field of iron and steel metallurgy, can solve the problems of low nitrogen content and few types of vanadium nitride alloys, and achieve the effects of high nitrogen yield, low cost, and stable nitrogen yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

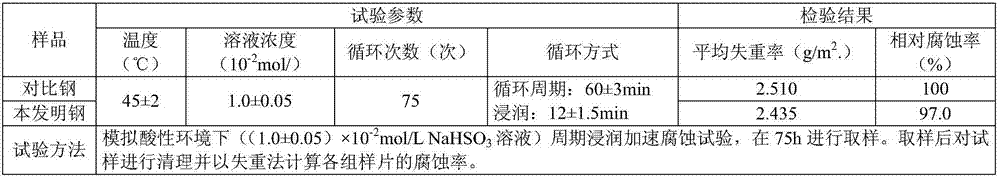

Embodiment 1

[0047] A steel plant adopts the technology of the present invention to produce ribbed steel bars for construction in the converter process with a nominal capacity of 120 tons (actual steel output is within the range of 120-140 tons). The production process is converter smelting → blowing inert gas after the furnace → LF furnace Heating → 6-machine 6-strand billet continuous casting machine casting into 150mm×150mm billet → billet heating → high-speed wire rolling into Ribbed steel bars.

[0048] Firstly, 120 tons of molten iron and 20 tons of scrap steel are added into the converter, and the S content of the added molten iron is less than 0.060%. After the molten iron and steel scrap are added to the converter, the molten iron and steel scrap are initially smelted into molten steel by using the function of the converter to remove C by blowing oxygen. When the composition of the molten steel is initially smelted to 0.06% C, 0.021% P, and 0.025% S, the temperature is 1659°C Wh...

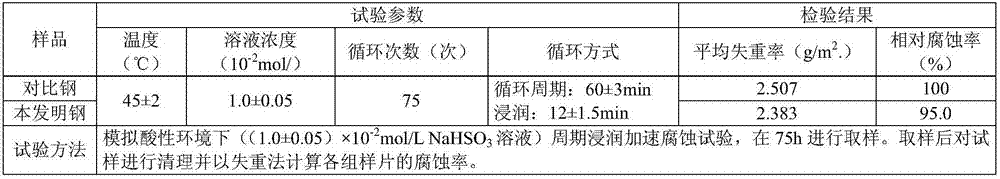

Embodiment 2

[0062] A steel plant adopts the technology of the present invention to produce ribbed steel bars for construction in the converter process with a nominal capacity of 120 tons (actual steel output is within the range of 120-140 tons). The production process is converter smelting → blowing inert gas after the furnace → LF furnace Heating → 6-machine 6-strand billet continuous casting machine casting into 150mm×150mm billet → billet heating → high-speed wire rolling into Ribbed steel bars.

[0063] Firstly, 120 tons of molten iron and 20 tons of scrap steel are added into the converter, and the S content of the added molten iron is less than 0.060%. After the molten iron and steel scrap are added to the converter, the molten iron and steel scrap are initially smelted into molten steel by using the function of the converter to blow oxygen to remove C. When the composition of the molten steel is initially smelted to 0.11% C, 0.020% P, and 0.025% S, the temperature is 1656°C When ...

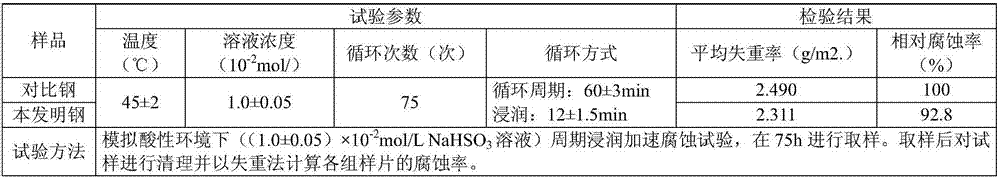

Embodiment 3

[0077] A steel plant adopts the technology of the present invention to produce ribbed steel bars for construction in the converter process with a nominal capacity of 120 tons (actual steel output is within the range of 120-140 tons). The production process is converter smelting → blowing inert gas after the furnace → LF furnace Heating → 6-machine 6-strand billet continuous casting machine casting into 200mm×200mm billet → billet heating → high-speed wire rolling into Ribbed steel bars.

[0078] Firstly, 120 tons of molten iron and 20 tons of scrap steel are added into the converter, and the S content of the added molten iron is less than 0.060%. After the molten iron and steel scrap are added to the converter, the molten iron and steel scrap are initially smelted into molten steel by using the function of the converter to remove C by blowing oxygen. When the composition of the molten steel is initially smelted to 0.11% C, 0.025% P, and 0.022% S, the temperature is 1677°C Wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com