Welding process and welding electric power unit

A welding method and technology of a power supply device, applied in welding equipment, arc welding equipment, manufacturing tools, etc., capable of solving problems such as defects in welding parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

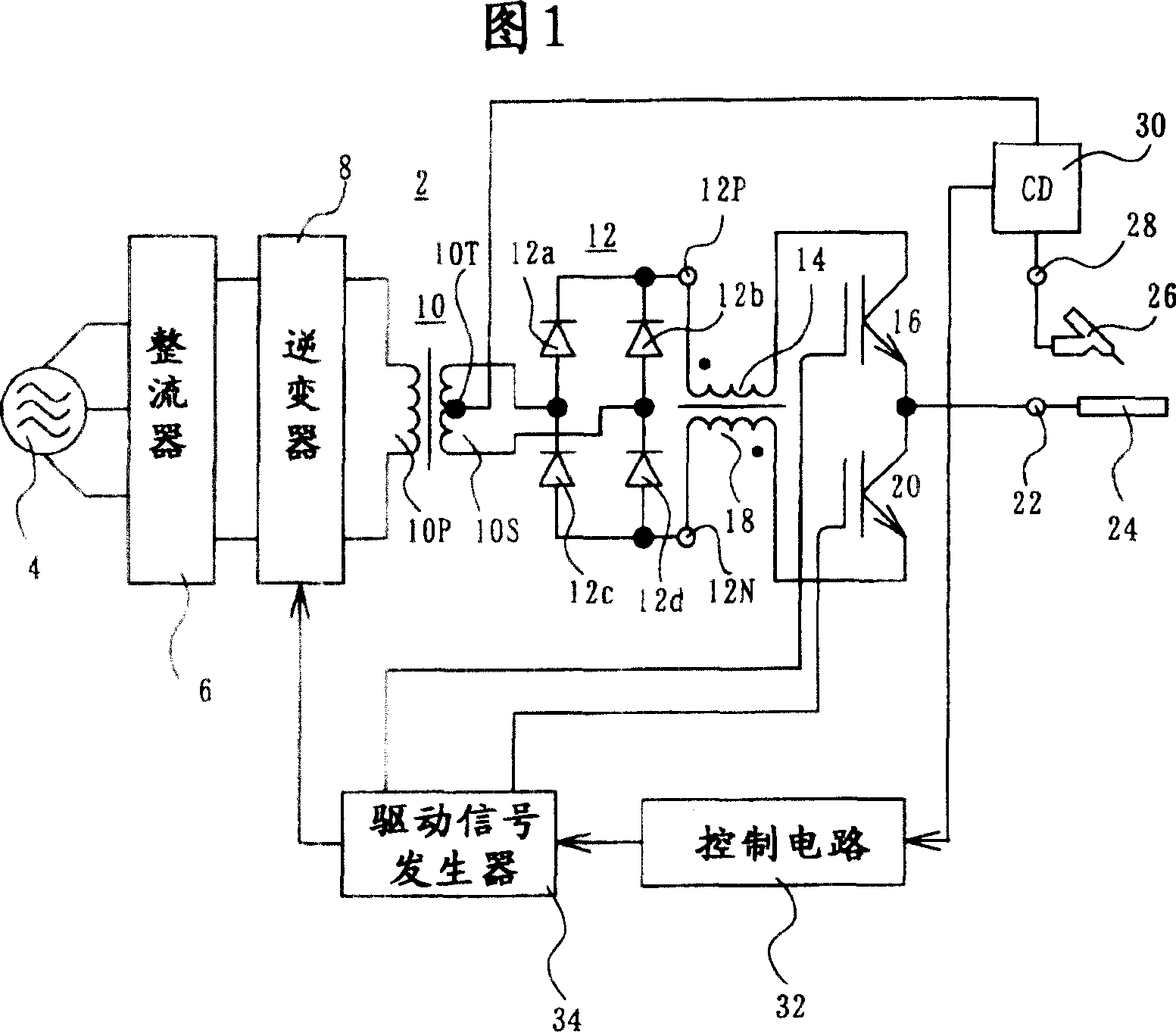

[0019] FIG. 1 shows a welding power supply device according to an embodiment of the present invention, which can be used for tungsten inert gas (arc) welding (TIG), and includes a DC power supply 2 .

[0020] The DC power supply 2 includes a rectification circuit 6 for rectifying the AC voltage output from, for example, the commercial AC power supply 4 . The rectified output of the rectification circuit 6 is supplied to a DC-to-high frequency conversion device, such as an inverter 8, through which it is converted into a high frequency voltage.

[0021] The high-frequency voltage is then supplied to the primary coil 10P of the transformer 10 . The secondary winding 10S of the transformer 10 has a center tap 10T. The high-frequency voltage induced in the secondary coil is rectified in a rectification circuit 12 . The rectification circuit 12 includes diodes 12a, 12b, 12c and 12d. The anode of the diode 12a is connected to one terminal of the secondary coil 10S, and the anode ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com