Method for separating condensed liquid in gas mixture by low pressure common cooling process

A technology for separating gas and condensate, which is applied in refrigeration and liquefaction, liquefaction, solidification, etc., can solve the problems of complex structure, large footprint, and bulky equipment, achieve high separation accuracy, save floor space, and equipment little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

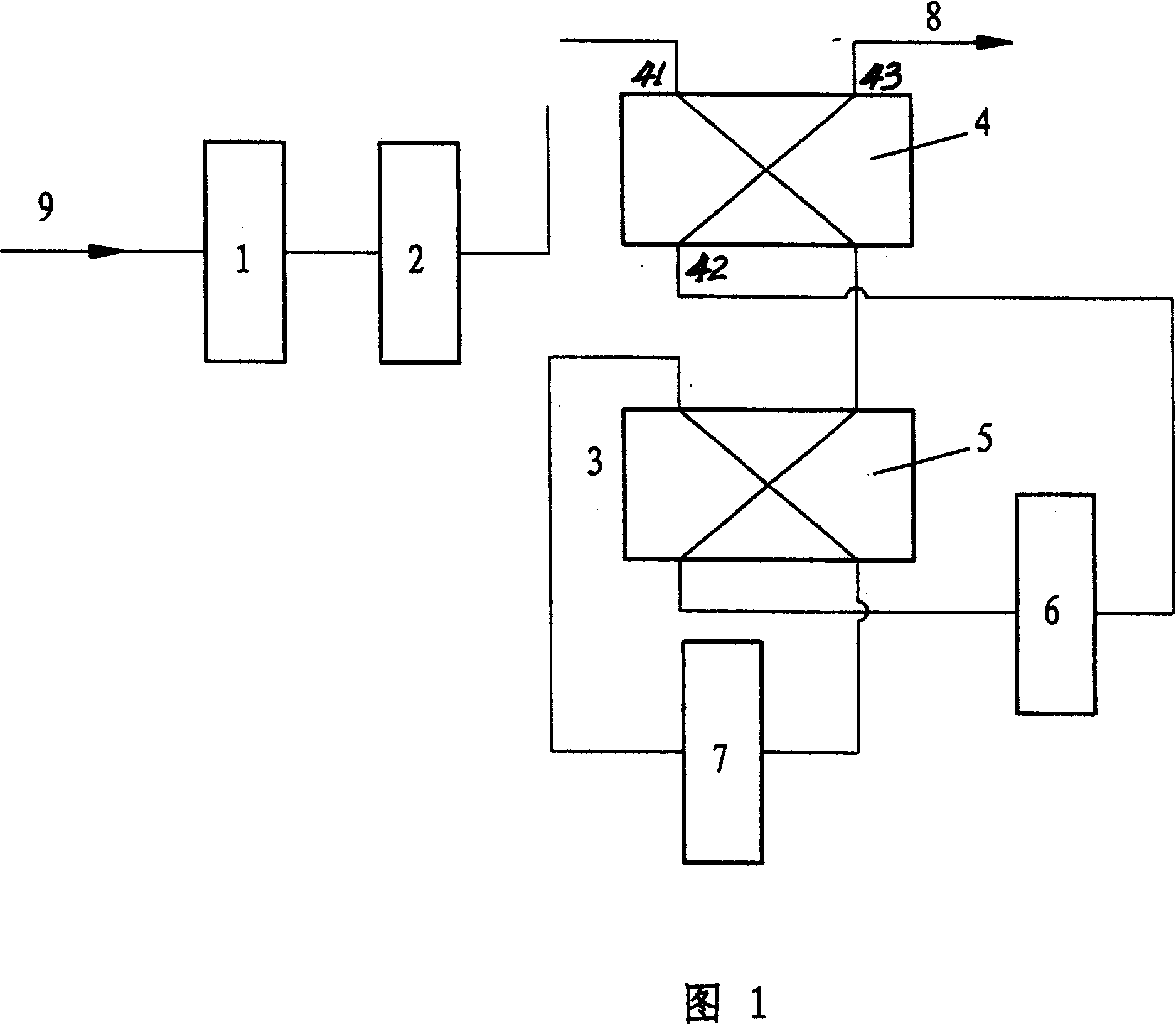

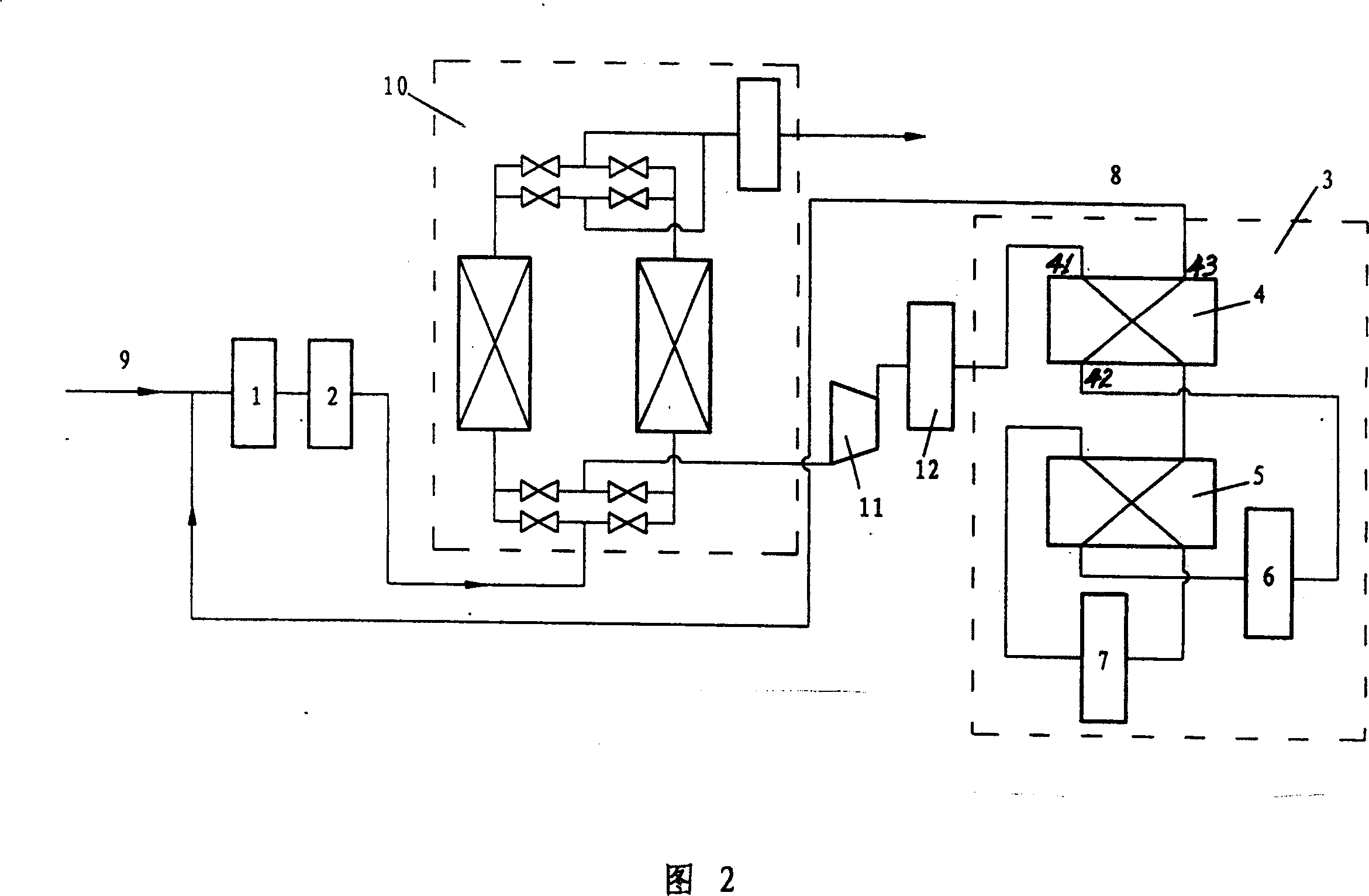

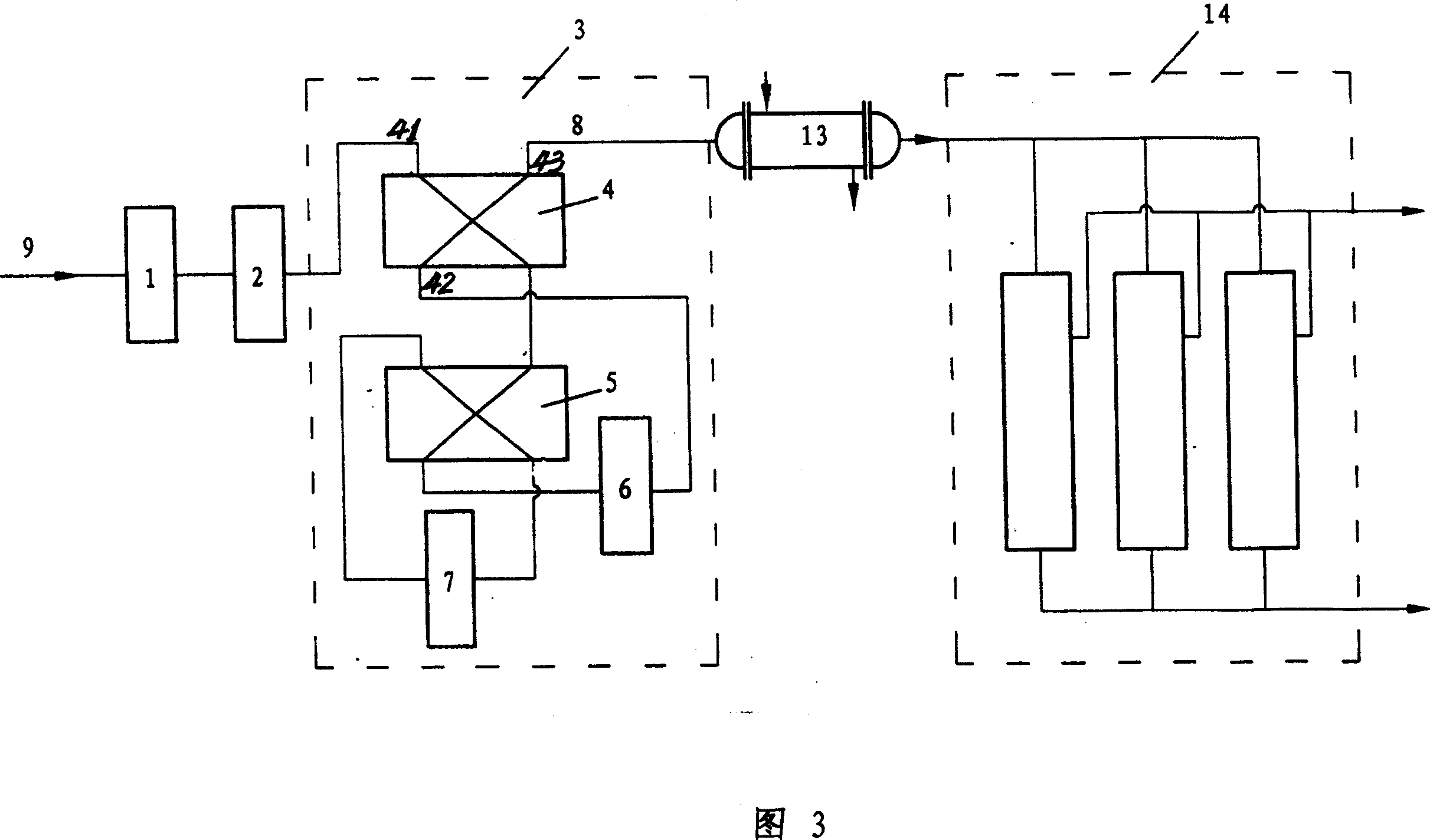

[0034] Referring to Fig. 1 is the basic type of the present invention, which is applicable to various working conditions that require condensation and separation, such as natural gas dehydration and condensate recovery, organic vapor condensation recovery, pretreatment before membrane separation devices, etc. The method includes

[0035] 1). Separation, the gas to be treated enters the separator 1 through the inlet pipe 9 for rough separation, and the solid and liquid impurities of large particles in the gas are separated;

[0036] 2). Re-separation, the gas after rough separation is filtered through the pre-filter 2, and the solid impurities and free condensate are separated;

[0037] 3). Heat exchange cooling, the separated and filtered gas enters the precooling / heater 4 in the refrigerator 3, and is cooled by heat exchange with the cold air from the evaporator 5; the compressor 7 in the refrigerator 3 is Refrigeration Compressors;

[0038] 4).Condensation and liquefaction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com