Shallow trench isolation structure making method

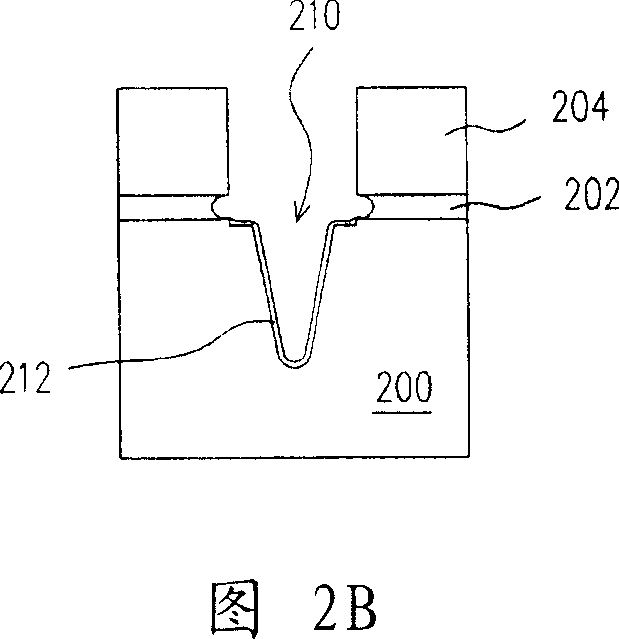

A technology of isolation structure and manufacturing method, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as component leakage current, liner 212 damage, shallow trench isolation structure 216 poor isolation function, etc., to achieve The effect of uniform thickness and avoiding leakage current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Next, the embodiments of the present invention will be described in detail, and the embodiments will be explained with the accompanying drawings. The depiction is in simplified form and not exact dimensions.

[0041] 3A to 3G are cross-sectional views of a manufacturing process of a preferred shallow trench isolation structure of the present invention.

[0042] Referring to FIG. 3A , the present invention provides a method for manufacturing a shallow trench isolation structure. Firstly, a substrate 300 is provided, and a pad layer 302 is formed on the substrate 300. The material of the pad layer 302 includes silicon dioxide, and the formation method is, for example, a thermal oxidation method. Of course, the material of the liner layer 302 may also be any other suitable material. Then, a silicon liner layer 304 is laid on the liner layer 302 . The material of the silicon liner layer 304 includes polysilicon, amorphous silicon, or single crystal silicon, and its forma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com