High pressure automatic control power oil tank for reinforcing steel bar upsetting equipment

A high-pressure, dynamic technology, applied in the field of high-pressure automatic control power tank, can solve the problems of unstable output pressure, unstable heading quality, etc., and achieve the effect of reliable work, convenient operation process and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

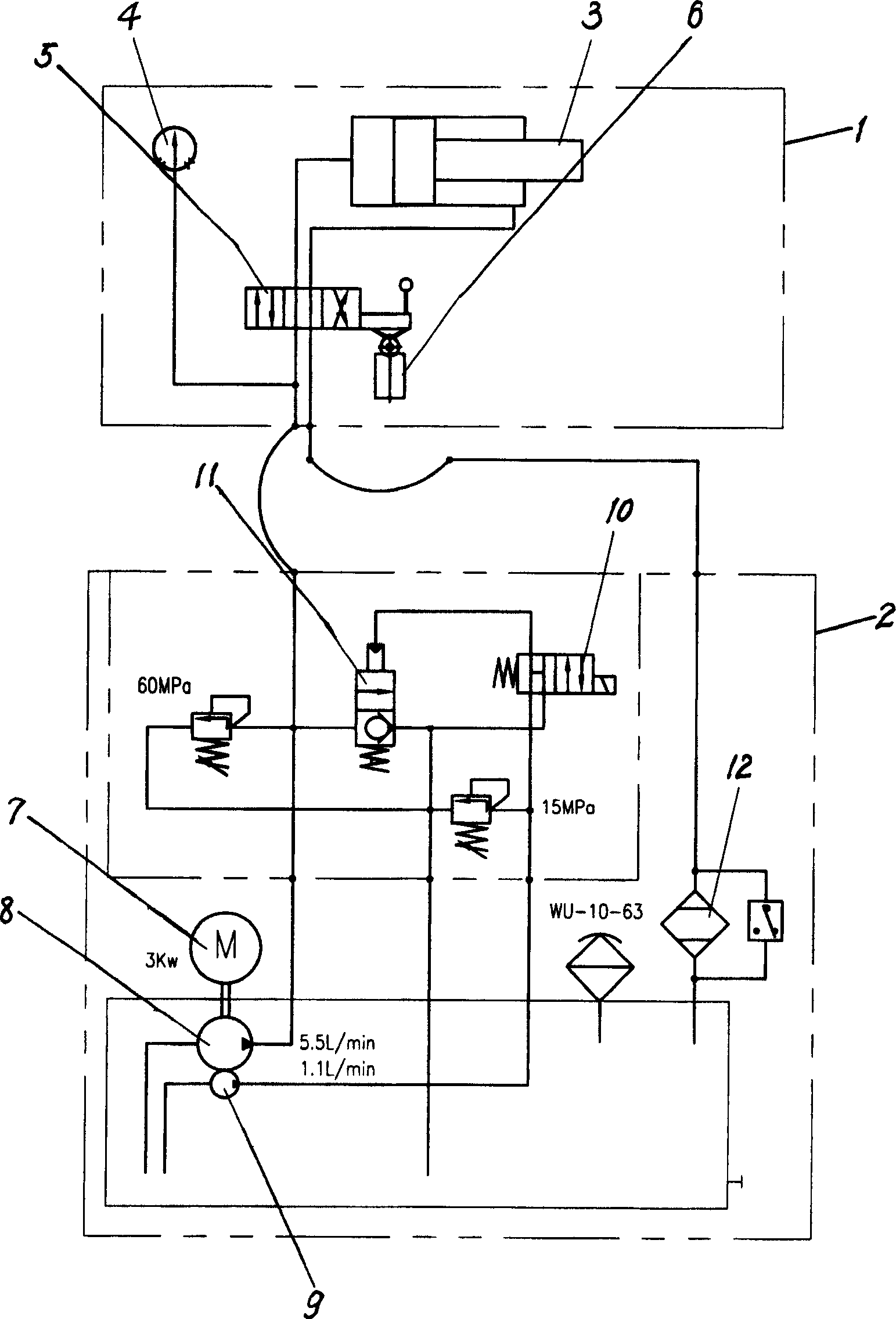

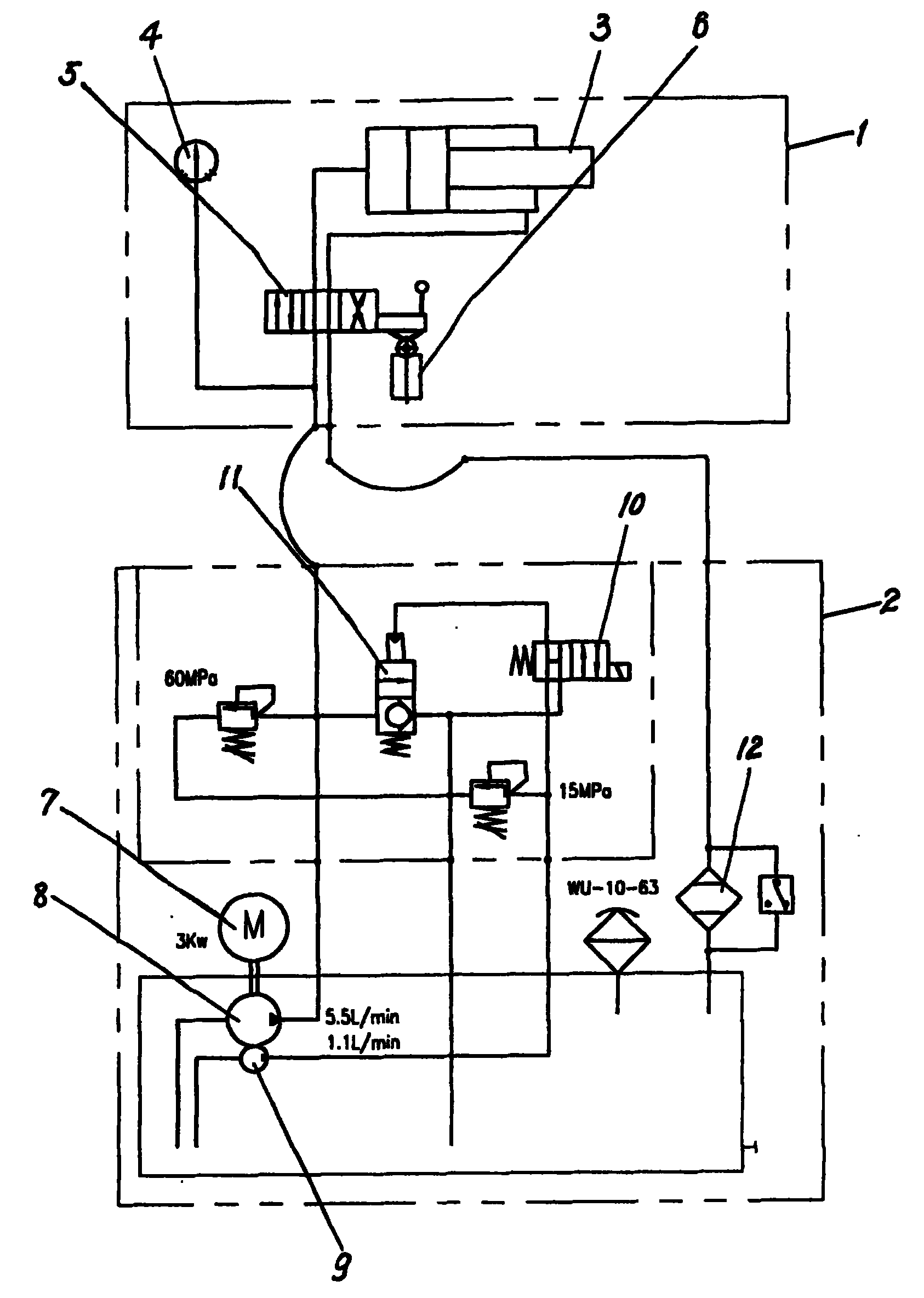

[0015] Referring to the accompanying drawings, the present invention is a high-pressure automatic control power oil tank for steel bar upsetting equipment, which includes a main engine 1 and a power oil tank 2, and the main engine 1 is equipped with a working device 3, a pressure gauge 4, a reversing valve 5 and a reset valve. Switch 6, motor 7, main pump 8, auxiliary pump 9, two-position solenoid valve 10 and hydraulic control check valve 11 are housed in power oil tank 2.

[0016] The pressure gauge 4 is a magnetic-assisted two-upper limit electric contact pressure gauge, and the pressure gauge 4 outputs a control signal. The reversing valve 5 is a three-position reversing valve, and the reversing valve 5 is connected with the main pump 8 . The two-position solenoid valve 10 and the hydraulic control check valve 11 are connected with the auxiliary pump 9 . The two-position solenoid valve 10 controls the oil circuit to drive the hydraulic control check valve 11 to realize sy...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap