Liquid-crystal displaying device and producing method thereof

A technology of liquid crystal display and manufacturing method, applied in instruments, nonlinear optics, optics and other directions, can solve the problems of damage to the multilayer film structure, time-consuming and labor-intensive, etc., so as to shorten the time course of the operation, reduce the cost, and avoid errors. effect of possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

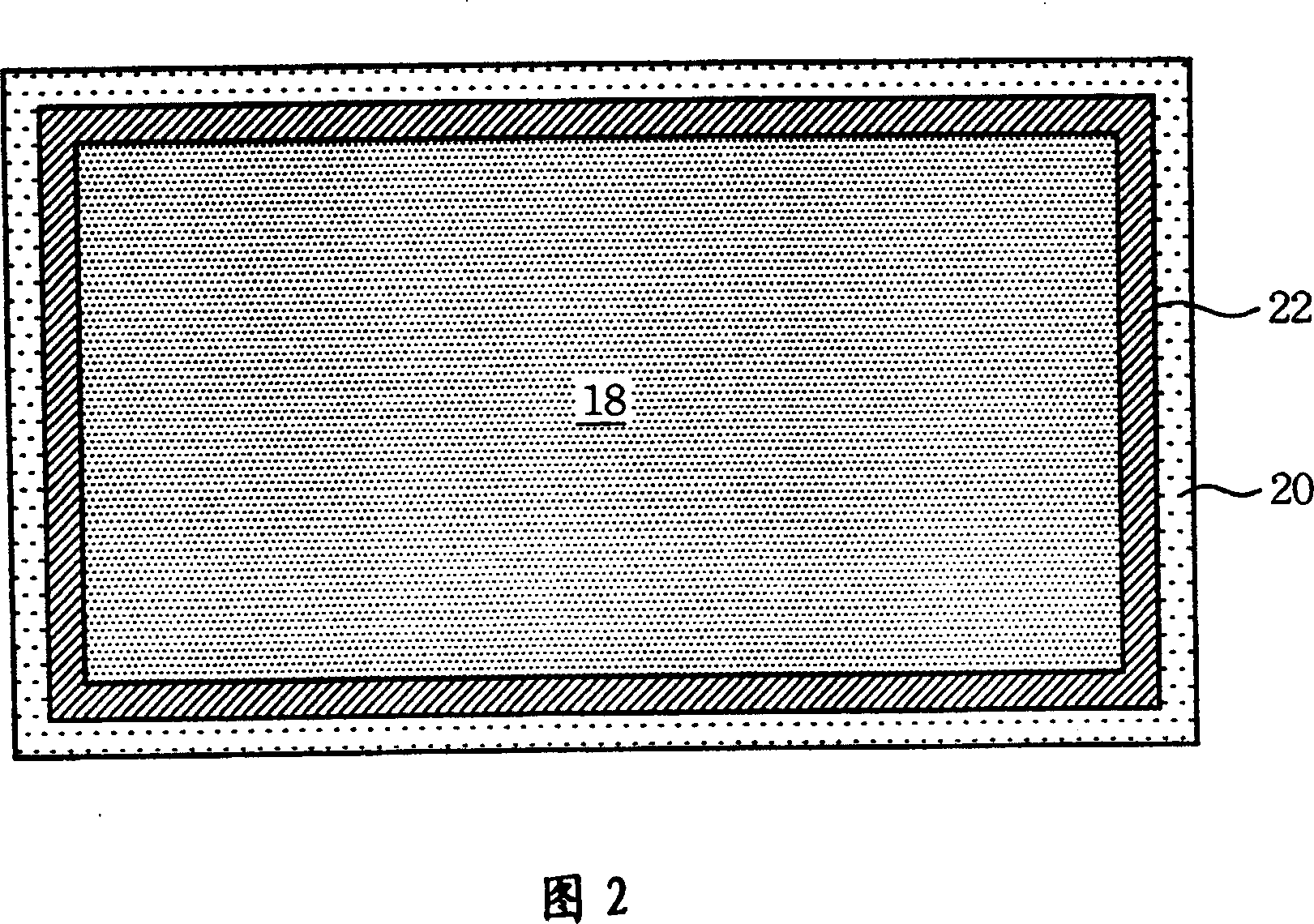

[0034] As shown in FIG. 6, the liquid crystal display of the present invention forms a light-shielding material 60 in a specific area around the lower and upper polarizers 28, 30, so that only the lower and upper polarizers 29, 30 need to be bonded to the liquid crystal panel during the assembly operation. 23, the effect of preventing light leakage can be achieved, and thereby the utilization rate of the light source of the present invention can be improved.

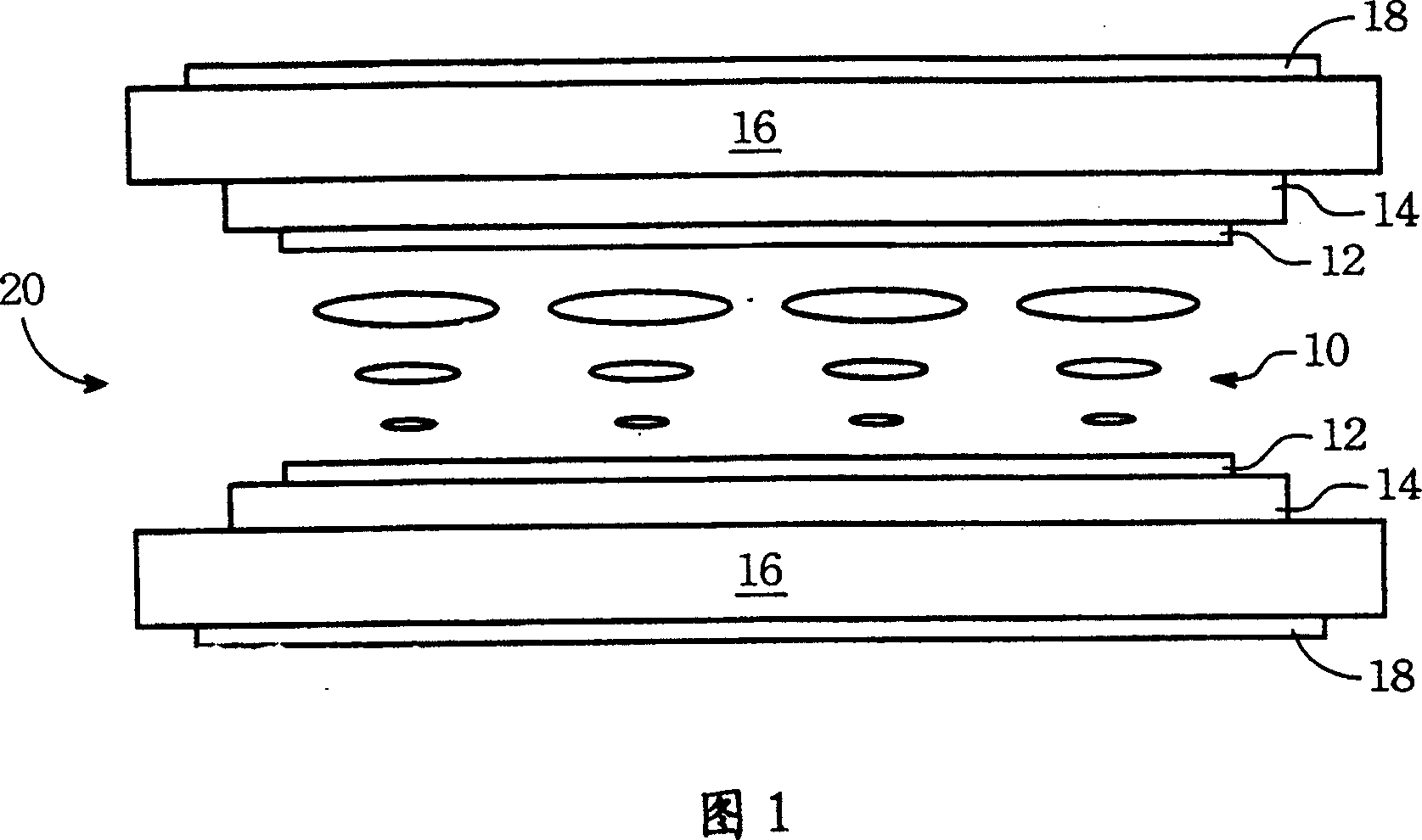

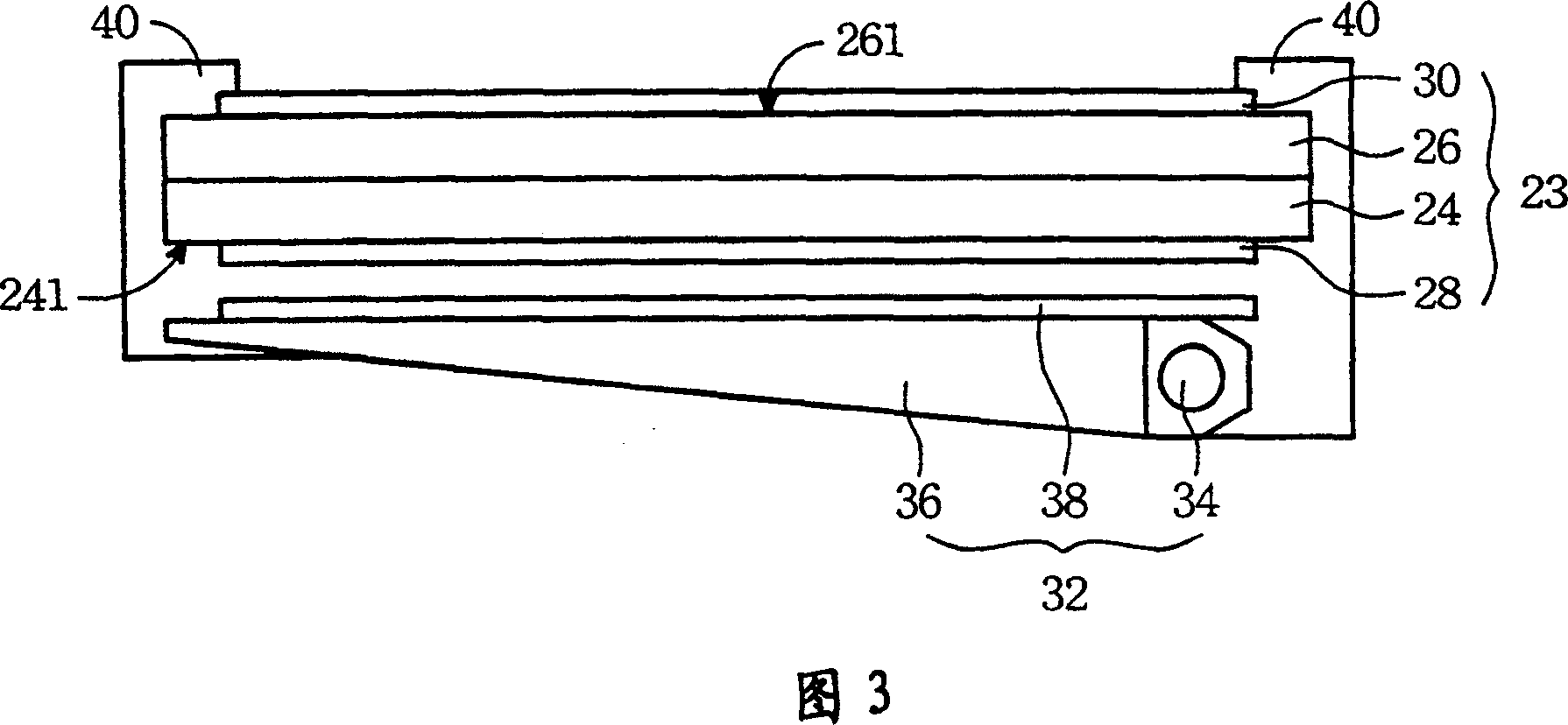

[0035] As shown in FIG. 3 , the liquid crystal display of the present invention includes a liquid crystal panel 23 , a lower polarizer 28 , an upper polarizer 30 , a backlight module 32 and an outer frame 40 located below the liquid crystal panel 23 as the light source of the liquid crystal display of the present invention.

[0036] As shown in FIG. 4 , the liquid crystal panel 23 includes a lower transparent substrate 24 , an upper transparent substrate 26 and a liquid crystal layer 25 .

[0037] The lower surface of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com