Bamboo-wood composite section bar production method

A composite profile and manufacturing method technology, applied in the direction of manufacturing tools, wood layer products, wood processing utensils, etc., can solve the problems of bamboo fiber structure damage, reducing the utilization rate of raw materials, tight supply of raw materials, etc., to achieve high utilization rate and price. Inexpensive, small glue surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

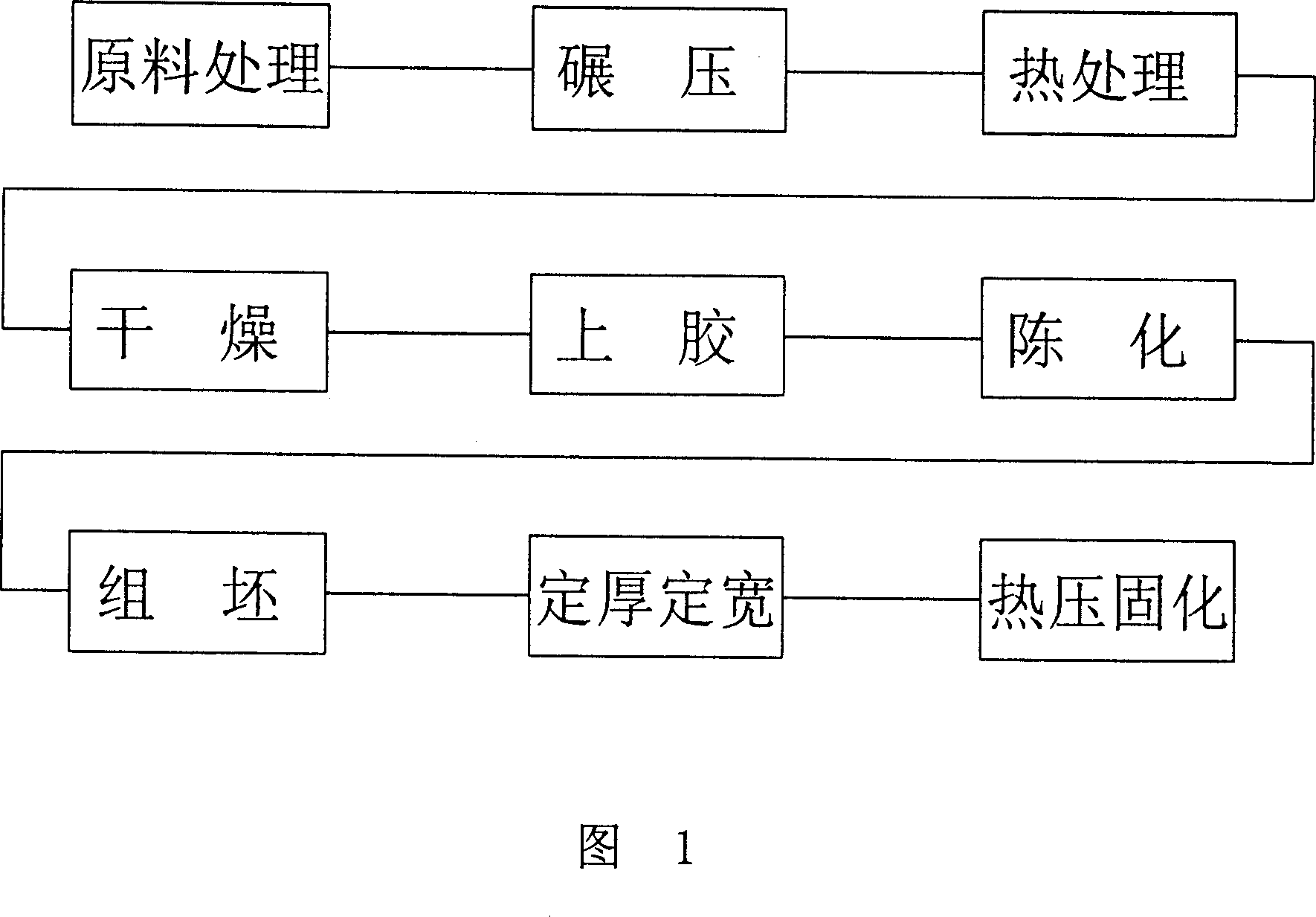

[0013] As shown in the figure, the manufacturing process of bamboo-wood composite profiles is as follows:

[0014] Raw material processing: Saw the bamboo and wood according to the specifications, then remove the green of the bamboo and peel the wood.

[0015] Rolling: Press the raw materials into blanks with unequal cracks, the thickness is 2-5mm, the width is 2-30mm, and the length is optional.

[0016] Blank heat treatment, drying, gluing, and aging: Heat treatment is to soak the blank in a hot water pool or pass it through steam to achieve the purpose of softening, anticorrosion, and mildew resistance. When drying, the moisture content is controlled at 8-10%. The rubber material is modified phenolic glue, and the glue content of the blank is controlled at 3.5-4.5%. Aging means that the glued raw materials are left for a period of time to make the glue more uniform in the material.

[0017] Blank assembly: Bamboo-wood composite integrated blank assembly, the upper and lowe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com