Gearing reducer made of magnesium alloy for electric children vehicle, and art for commercialized prodn. of same

A technology for gear reduction boxes and electric baby carriages, which is applied to vehicle gearboxes, vehicle parts, wheel transmissions, etc., and can solve the problems of electric baby carriages that cannot be used normally, reduction boxes that cannot work normally, and high mold manufacturing costs, and achieve simple structure , Saving heating energy consumption, the effect of simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

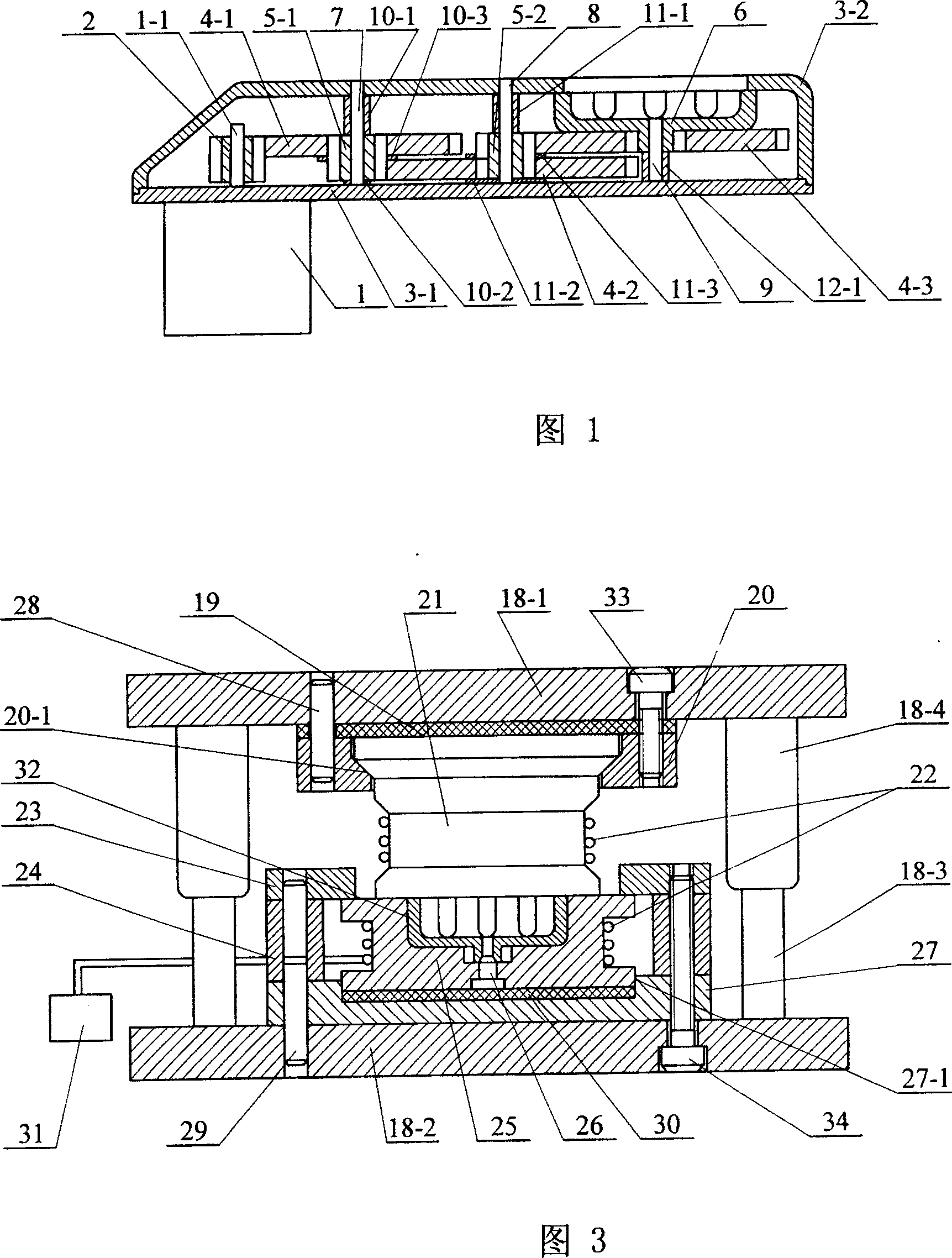

[0006] Specific Embodiment 1: This embodiment is described in conjunction with FIG. 1 . The electric stroller magnesium alloy gear reduction box of this embodiment consists of a housing composed of a base 3-1 and an outer cover 3-2, a motor 1, a main transmission gear 2, a thin gear, The thick gear, the gear shaft 6, the first shaft 7, the second shaft 8, the third shaft 9, the first positioning device, the second positioning device, and the third positioning device; the thin gear is composed of the first thin gear 4- 1. The second thin gear 4-2 and the third thin gear 4-3; the thick gear is composed of the first thick gear 5-1 and the second thick gear 5-2; the motor 1 is fixed on the base of the housing 3-1 on the outer panel, the output shaft 1-1 of the motor 1 is installed in the housing, the output shaft 1-1 of the motor 1 is equipped with the main transmission gear 2, the main transmission gear 2 and the outer surface of the first thin gear 4-1 The ring gear meshes, the ...

specific Embodiment approach 2

[0008] Specific embodiment two: This embodiment is described in conjunction with Fig. 1. The first positioning device of this embodiment is composed of a first positioning sleeve 10-1, a first positioning pad 10-2, and a second positioning pad 10-3; The first positioning sleeve 10-1 is housed on the first shaft 7 between the outer cover 3-2 and the first thick gear 5-1, and the first shaft between the base 3-1 of the housing and the first thick gear 5-1 7 is equipped with a first positioning pad 10-2, and the first thick gear 5-1 between the first thin gear 4-1 and the second thin gear 4-2 is equipped with a second positioning pad 10-3. Using the sawn metal tube as the first positioning sleeve 10-1 and cooperating with the first positioning pad 10-2 and the second positioning pad 10-3 (using standard washers) can realize the fast positioning of the first thick gear 5-1. Axial positioning. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0009] Specific embodiment three: This embodiment is described in conjunction with FIG. 1. The second positioning device of this embodiment is composed of a second positioning sleeve 11-1, a third positioning pad 11-2, and a fourth positioning pad 11-3; The second positioning sleeve 11-1 is housed on the second shaft 8 between the outer cover 3-2 and the second thick gear 5-2, and the second shaft between the base 3-1 of the housing and the second thick gear 5-2 The third positioning pad 11-2 is housed on 8, and the fourth positioning pad 11-3 is housed on the second thick gear 5-2 between the second thin gear 4-2 and the third thin gear 4-3. Adopt the sawn metal tube as the second positioning sleeve 11-1 and cooperate with the third positioning pad 11-2 and the fourth positioning pad 11-3 (using standard washers) to realize the rapid operation of the second thick gear 5-2. Axial positioning. Other components and connections are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com