High light output quick attenuation flash ceramic and its preparing method

A technology of scintillation ceramics and high gloss applied in the field of scintillation ceramics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

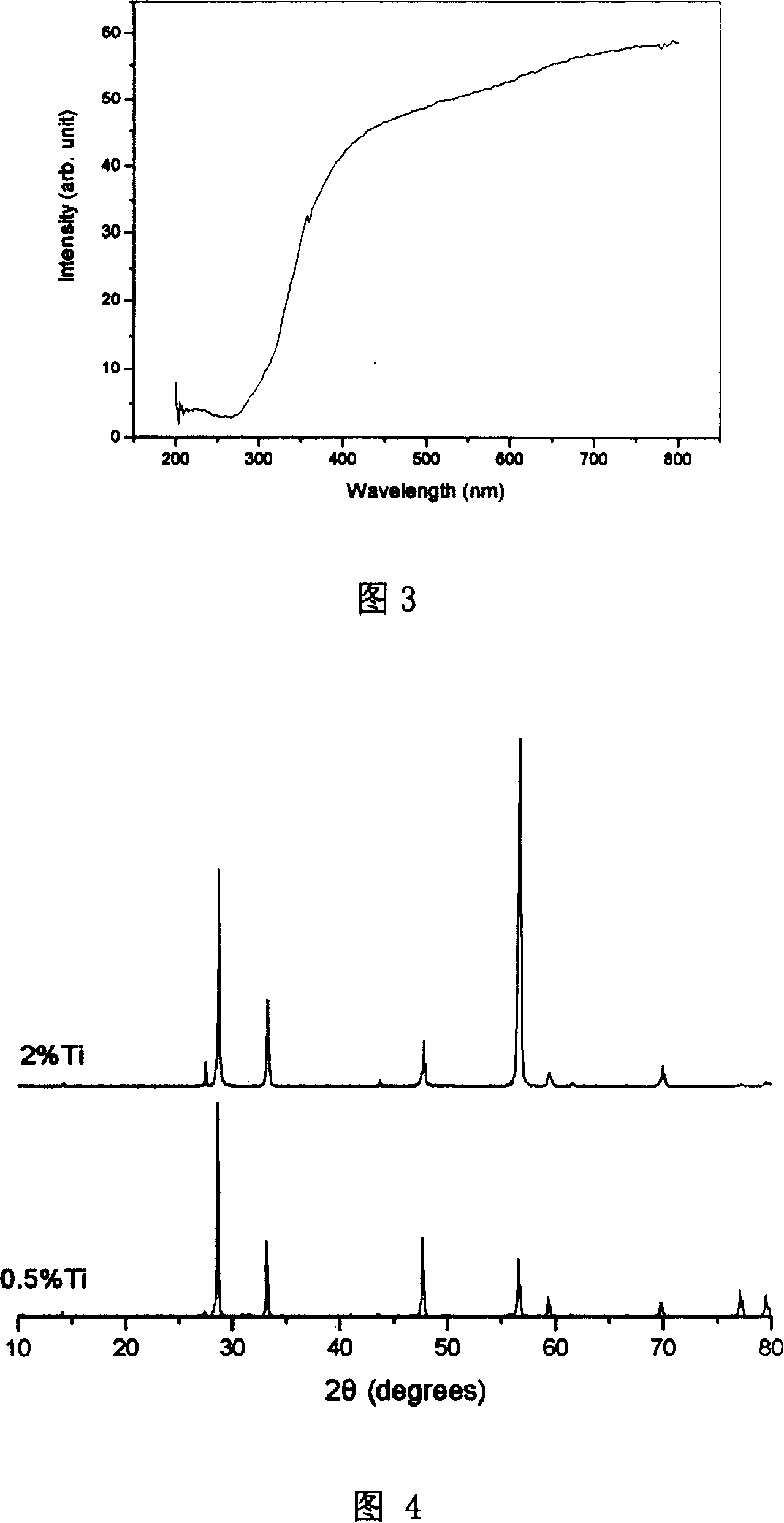

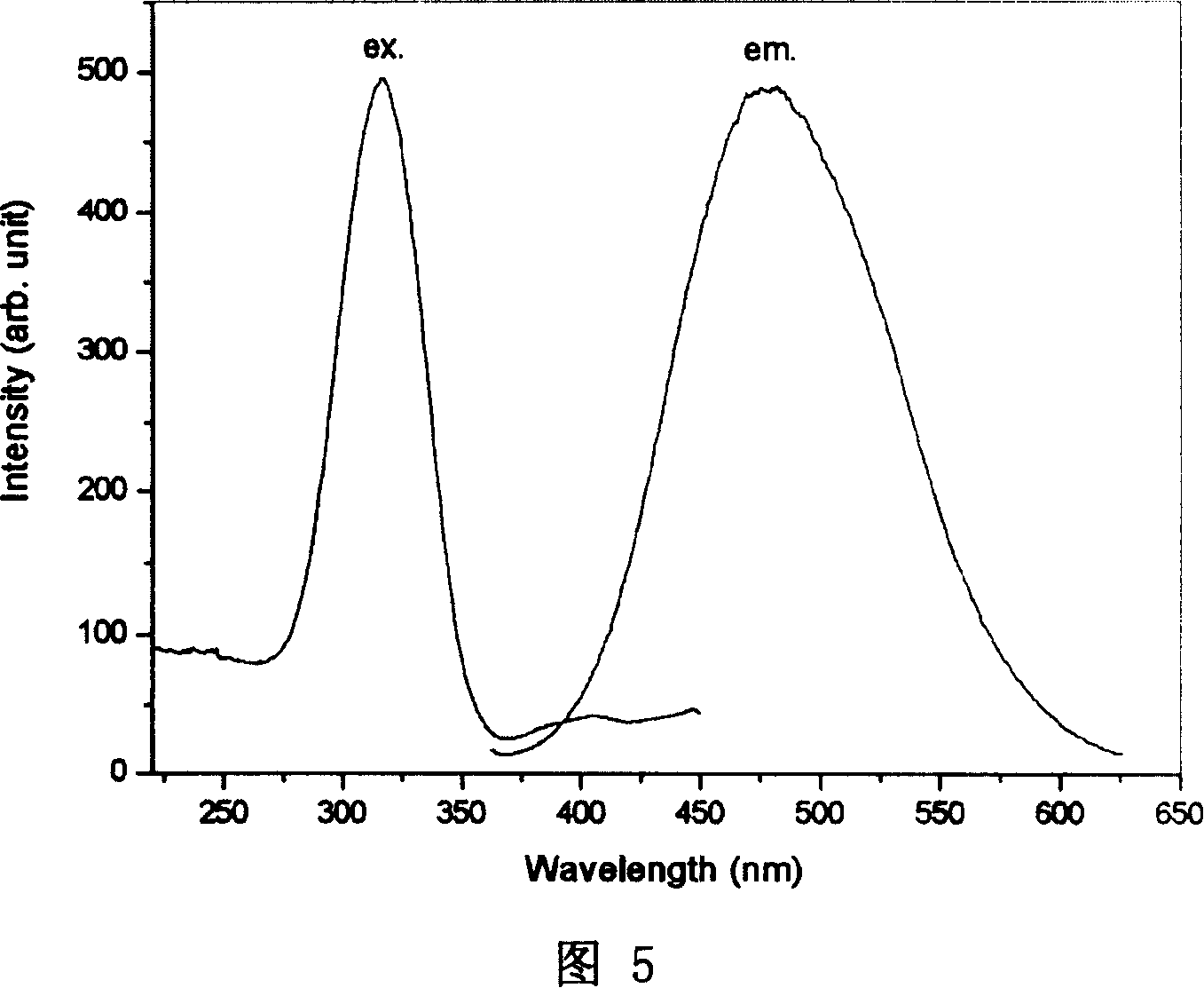

[0032] 0.0199 mol HfO(NO 3 ) 2 , 0.0001 mol TiO(NO 3 ) 2 , 0.02 mol La(NO 3 ) 3 The powder prepared by combustion reaction with 0.054 mol glycine was calcined at 800°C for 2 hours to remove residual carbon and organic matter. Calcined and combusted La 2 Hf 2 o 7 The powder is first subjected to isoaxial pressing, and then isostatically pressed at 180MPa. The products formed by isostatic pressing are kept in a hydrogen atmosphere at 1900°C for 6 hours. The sintered samples were annealed at 1150°C for 4 hours in an air atmosphere.

[0033] The composition and properties of the obtained transparent scintillation ceramics are as follows:

[0034] Composition: La 2 Hf 1.99 Ti 0.01 o 7

[0035] Relative density: >99.9%

[0036] Density (g / cm 3 ): >7.8

[0037] Crystal phase (X diffraction analysis): La 2 Hf 2 o 7

[0038] Porosity (%): <0.1

[0039] 400-800nm band maximum transmittance (%): >50

[0040] Light Output: Better than CaWO 4 scintillation crysta...

Embodiment 2

[0042] 0.0198 mol HfO(NO 3 ) 2 , 0.0002 mol TiO(NO 3 ) 2 , 0.02 mol La(NO 3 ) 3 The powder prepared by combustion reaction with 0.054 mol glycine was calcined at 800°C for 2 hours to remove residual carbon and organic matter. Calcined and combusted La 2 Hf 2 o 7The powder is first subjected to isoaxial pressing, and then isostatically pressed at 180MPa. The products formed by isostatic pressing are kept in a hydrogen atmosphere at 1900°C for 6 hours. The sintered samples were annealed at 1150°C for 4 hours in an air atmosphere.

[0043] The composition and properties of the obtained transparent scintillation ceramics are as follows:

[0044] Composition: La 2 f 1.98 Ti 0.02 o 7

[0045] Relative density: >99.9%

[0046] Density (g / cm 3 ): >7.8

[0047] Crystal phase (X diffraction analysis): La 2 f 2 o 7

[0048] Porosity (%): <0.1

[0049] 400-800nm band maximum transmittance (%): >50

[0050] Light Output: Better than CaWO 4 scintillation crystal ...

Embodiment 3

[0053] 0.0196 mol HfO(NO 3 ) 2 , 0.0004 mol TiO(NO 3 ) 2 , 0.02 mol La(NO 3 ) 3 The powder prepared by combustion reaction with 0.054 mol glycine was calcined at 800°C for 2 hours to remove residual carbon and organic matter. Calcined and combusted La 2 f 2 o 7 The powder is first subjected to isoaxial pressing, and then isostatically pressed at 180MPa. The products formed by isostatic pressing are kept in a hydrogen atmosphere at 1900°C for 9 hours. The sintered samples were annealed at 1200°C for 2 hours in an air atmosphere.

[0054] The composition and properties of the obtained transparent scintillation ceramics are as follows:

[0055] Composition: La 2 f 1.96 Ti 0.04 o 7

[0056] Relative density: >99.9%

[0057] Density (g / cm 3 ): >7.8

[0058] Crystal phase (X diffraction analysis): La 2 f 2 o 7

[0059] Porosity (%): <0.1

[0060] 400-800nm band maximum transmittance (%): >50

[0061] Light Output: Better than CaWO 4 scintillation crystal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com