Three-phase metering separator for oil, gas and water

An oil-water-gas separator technology, applied in the field of separators, can solve problems such as affecting the performance of three-phase separation, affecting the operation performance of equipment, and difficult to discharge sand, so as to ensure the smoothness of fluid flow, improve the smoothness of fluid flow, and avoid oil temperature lowering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

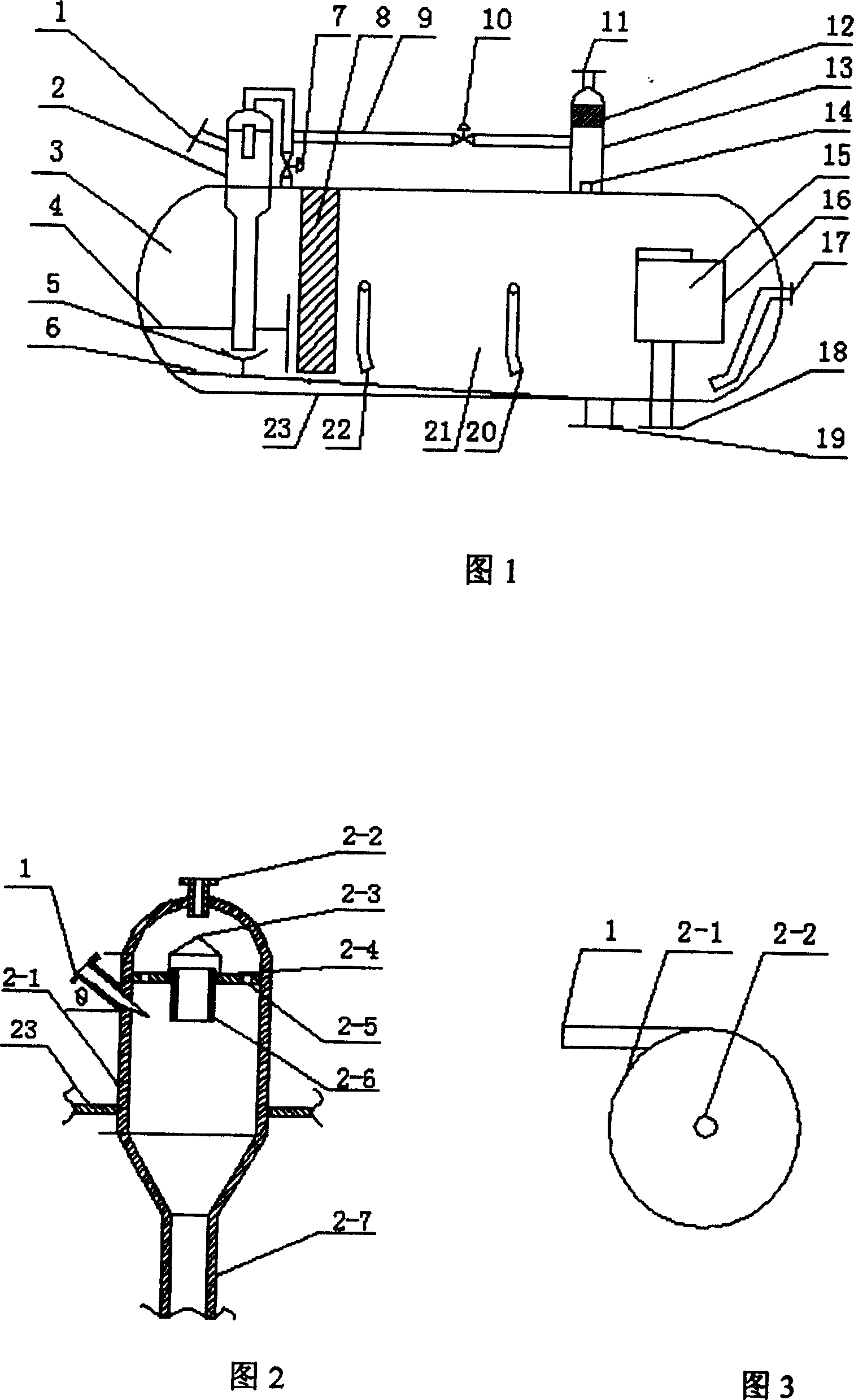

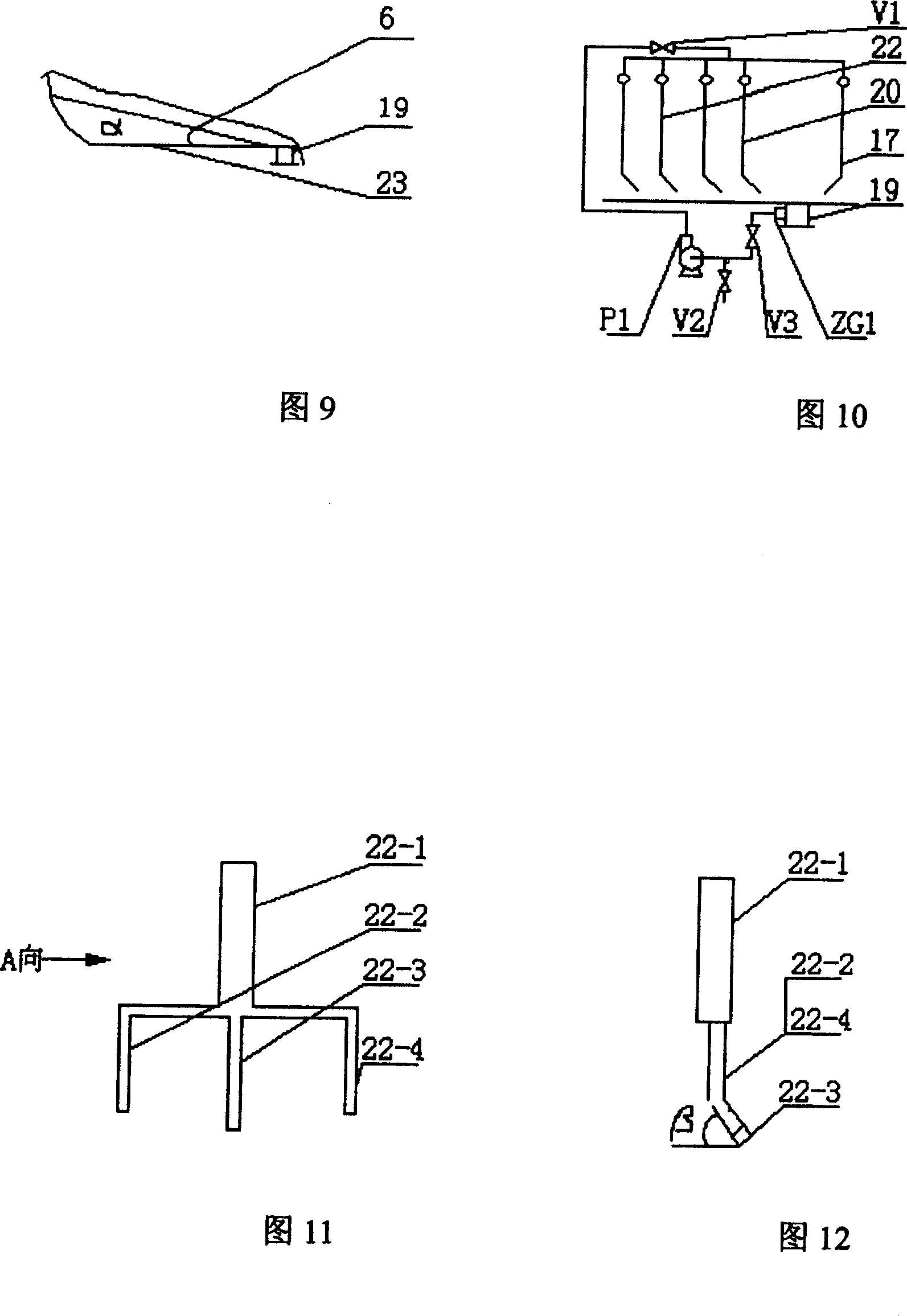

[0031] Oil-water-gas three-phase metering separator is composed of cyclone pre-degasser, energy dissipator, oil chamber, settling chamber, sand discharge system and other components.

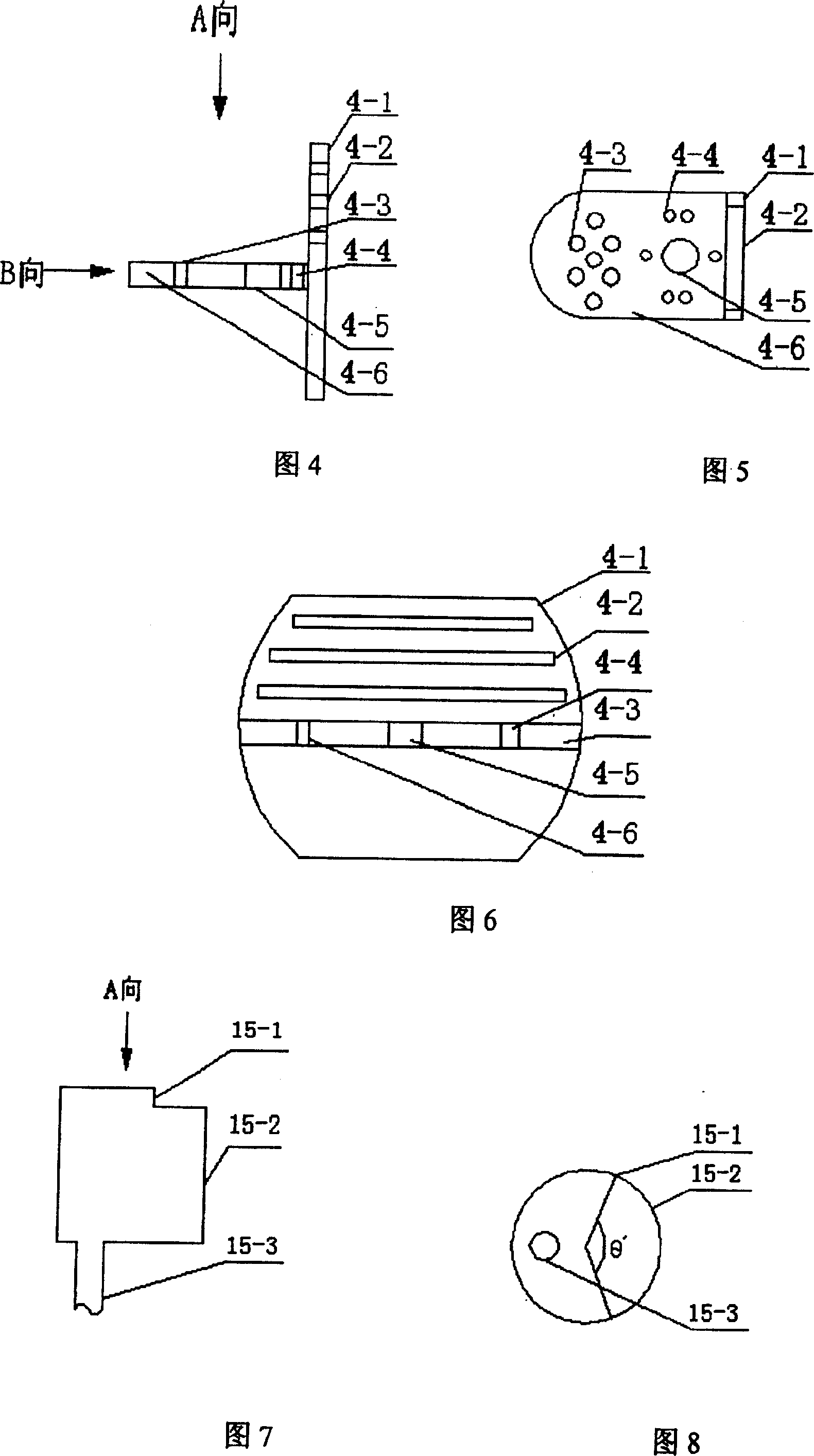

[0032] The separator used for three-phase metering of oil, water and gas includes a housing 23, a cyclone pre-degasser 2, an energy dissipator 4, an oil chamber 15, and a sand discharge system, wherein the body of the cyclone pre-degasser 2 has a main housing ( 2-1), the main shell is provided with a support plate (2-4), the periphery of the support plate is provided with a balance hole (2-5), the middle of the support plate is provided with a liquid retaining pipe (2-6), and the top of the liquid retaining pipe is provided with There is a fog catching cover (2-3), the upper end of the main shell is provided with a gas outlet connection pipe (2-2), the side wall of the main shell, and a tangential inlet pipe 1 is provided under the support plate, and the lower end of the main shell is provided wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com