Waterproof and thermal insulating roof structure for bungalow and construction process thereof

A technology for bungalows and waterproof layers, which is applied to roof insulation materials, building roofs, roof coverings, etc. It can solve the problems of disconnection between waterproof and heat insulation technology, easy leakage at joints, poor waterproof and heat insulation integrity, etc., and achieve sun protection Outstanding heat insulation effect, low cost, good waterproof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

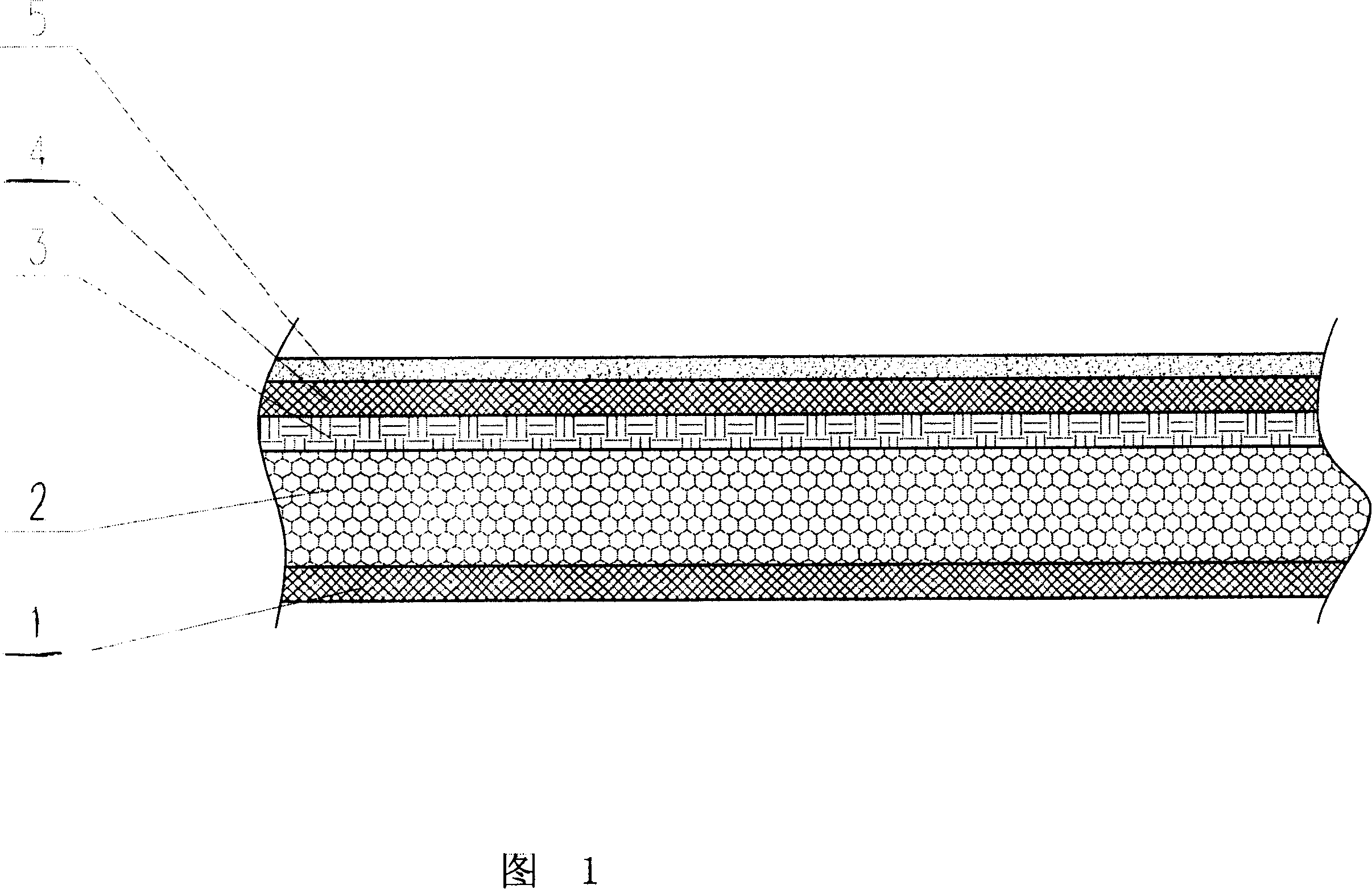

[0043] Referring to Fig. 1, a kind of flat roof waterproof heat-insulation roof structure provided by the present embodiment is to be provided with waterproof layer 1, insulation layer 2, grid glass fiber cloth layer 3, cover layer successively on the roof surface of building structure 4 and surface spray layer 5. Wherein waterproof layer 1 is similar to existing waterproof layer, and its thickness is 0.5-1.0mm; Described thermal insulation layer 2 is mixed by 107 glue, double fly powder, gray calcium powder, white cement and perlite, and its thickness is 4-1.0 mm. 6mm; the overcoat layer 4 is mixed with 107 glue, double fly powder, gray calcium powder and white cement, and its thickness is 0.5-1mm in total; the surface spray layer 5 is an organic silicon water-repellent layer, which The thickness is 0.01-0.02mm.

[0044] The construction technology of a flat roof waterproof and heat-insulating roof provided by the present invention comprises the following steps:

[0045] a....

Embodiment 2

[0053] The waterproof and heat-insulated roof structure of the flat roof provided in this embodiment is to be provided with a waterproof layer 1, an insulation layer 2, a mesh glass fiber cloth layer 3, an overlay layer 4 and a surface spray layer 5 in sequence on the roof surface of the building structure. ,As shown in Figure 1. Wherein waterproof layer 1 is similar to existing waterproof layer, and its thickness is 0.7-0.9mm; Described thermal insulation layer 2 is mixed by 107 glue, double fly powder, gray calcium powder, white cement and perlite, and its thickness is 5-0mm. 10mm; the overcoat layer 4 is formed by mixing 107 glue, double fly powder, lime calcium powder and white cement, and its thickness is 0.6-0.8mm in total; the surface spray layer 5 is a silicone water-repellent layer, Its thickness is 0.015-0.018mm.

[0054] The construction technology of a flat roof waterproof and heat-insulating roof provided by the present invention comprises the following steps:

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com