Raw state grain drying apparatus

A drying device and original ecological technology, which is applied in the direction of drying solid materials, heating to dry solid materials, drying, etc., can solve the problems of poor grain quality after drying, high operating costs, and small precipitation, and achieve easy operation and overall The effect of reasonable structure matching and low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

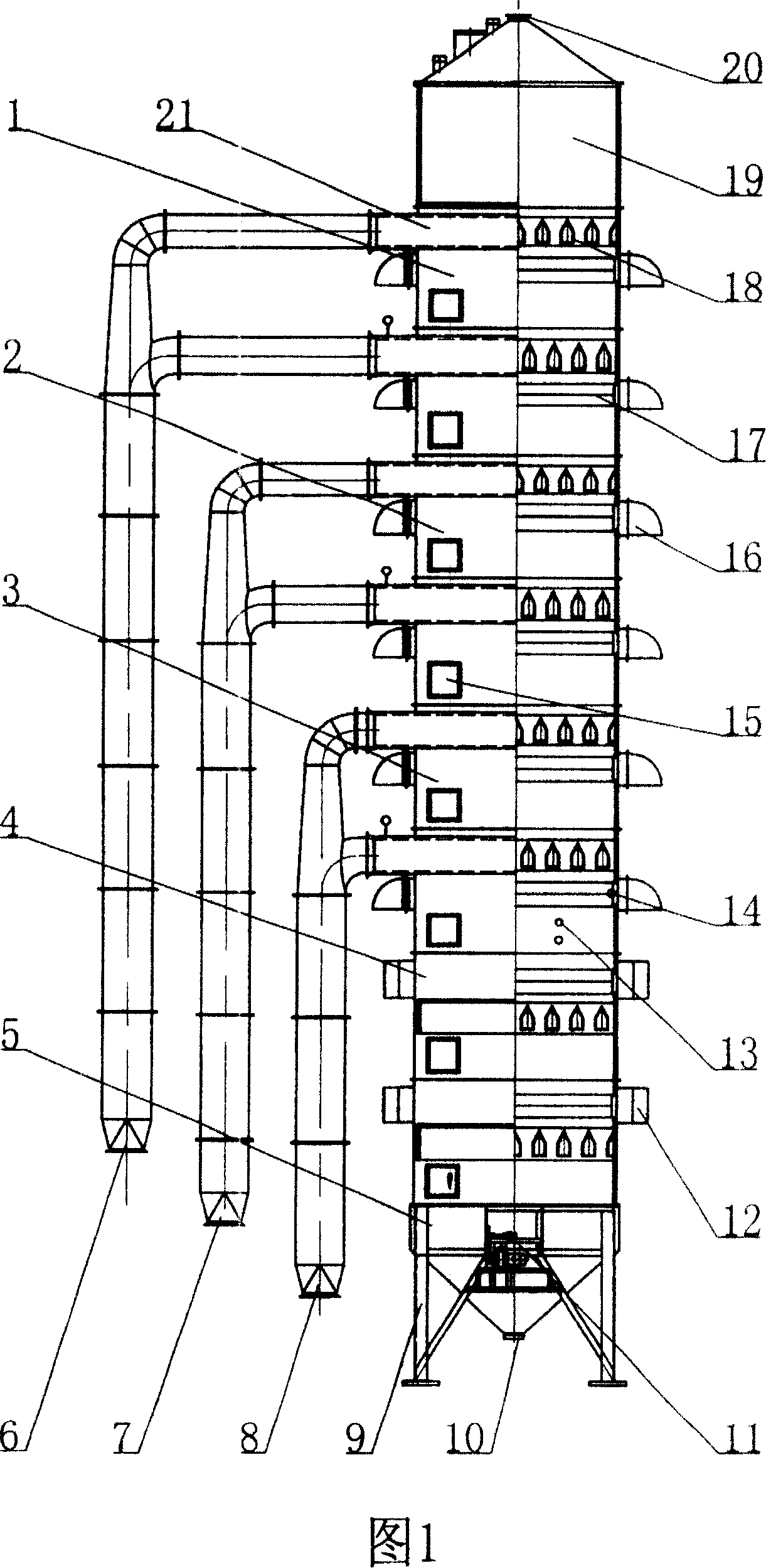

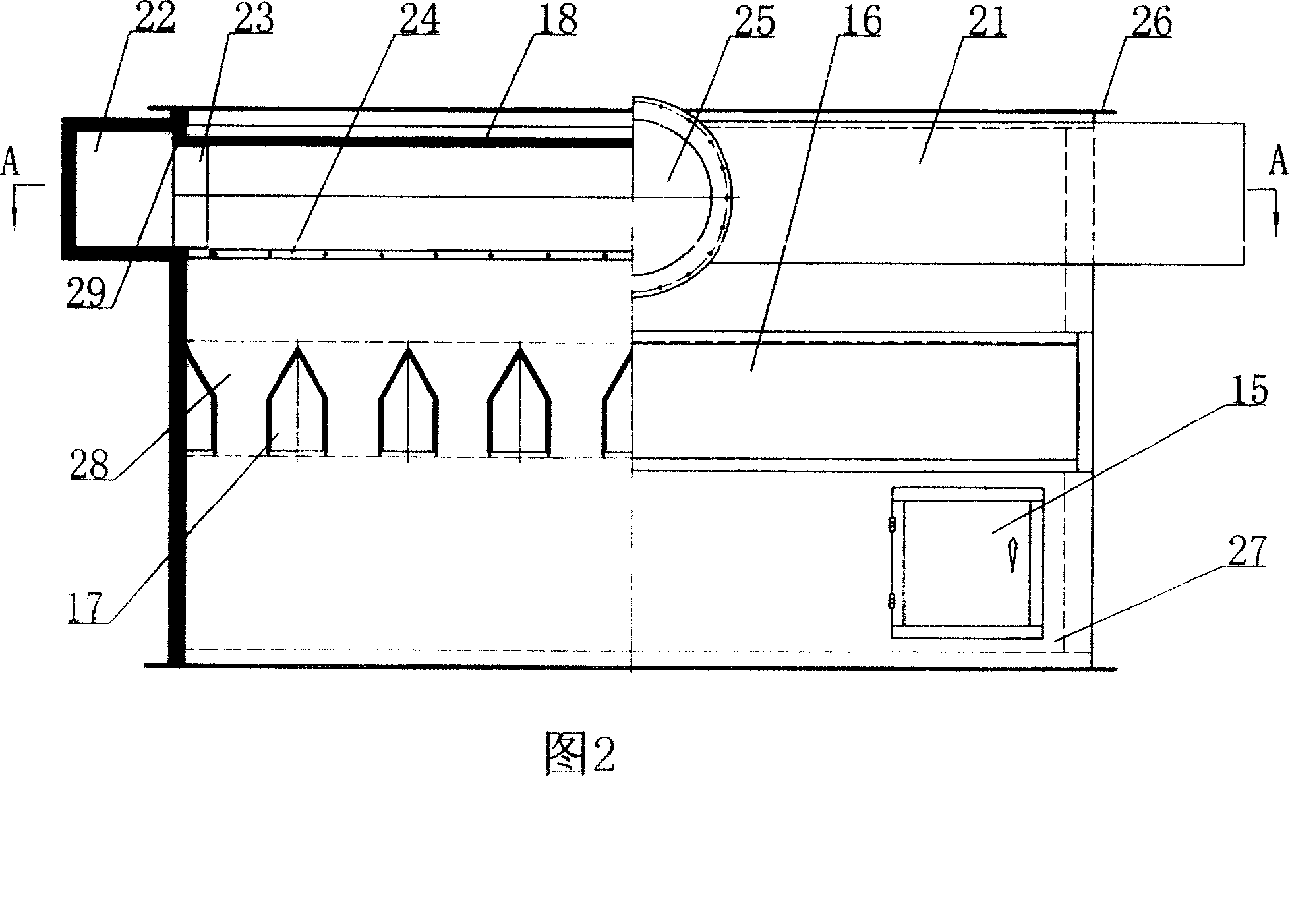

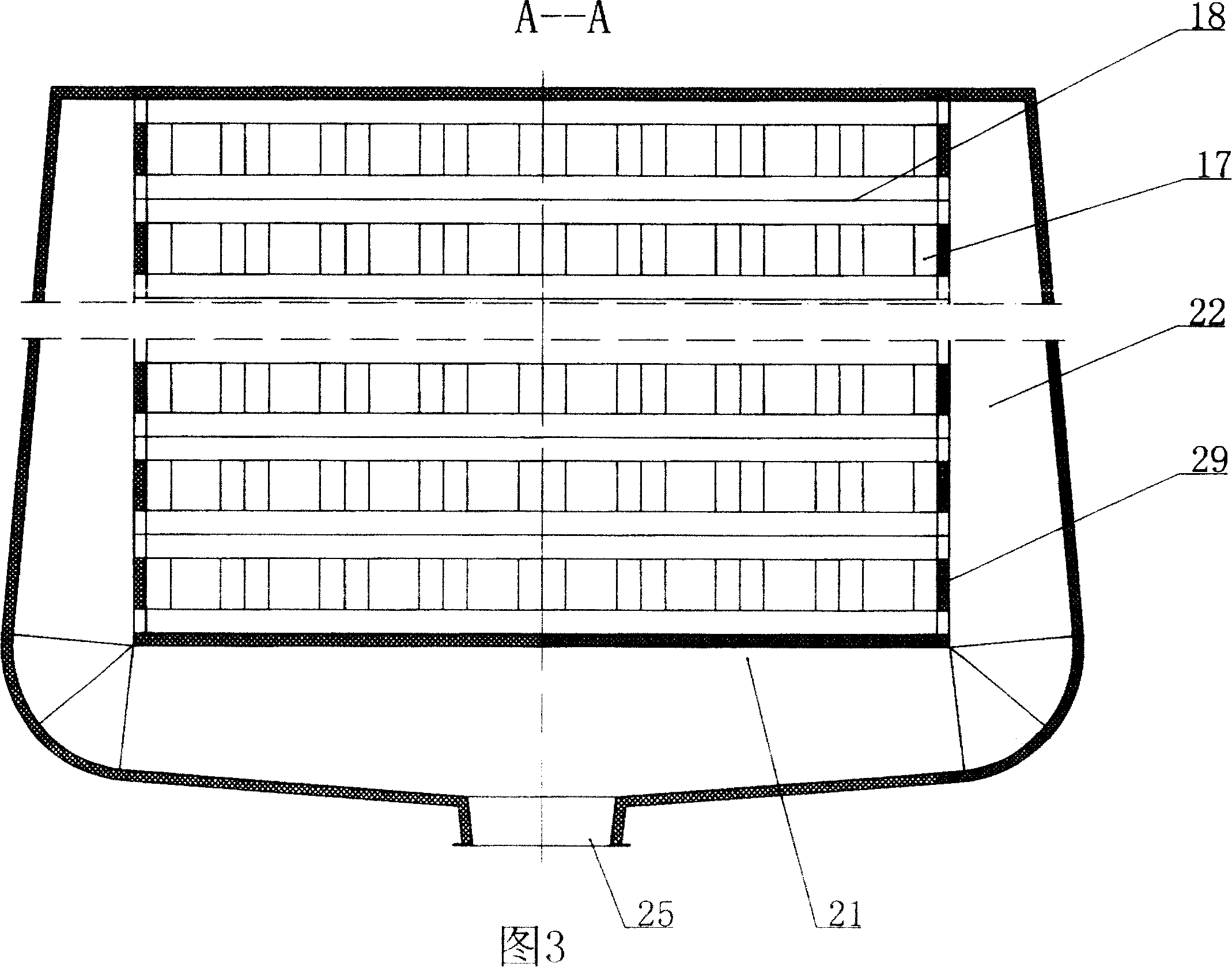

[0023] The specific structure and working process of the present invention will be described in detail according to Fig. 1-7. The device adopts a combined structure, including an upper grain storage bin 19, a lower grain row bin 5, and various sections of the body 27 with polygonal boxes assembled therebetween and a control device composed of a conventional heating device, a detection device, and a control circuit. The conventional heating device includes general equipment such as hot blast pipelines, heat exchangers, and hot blast stoves. High, medium and low temperature hot air inlets 6, 7, 8 enter the body 27 to provide high temperature hot air, medium temperature hot air and low temperature hot air to complete the drying of grain. The detection device includes the high and low material level devices that are commonly used in the upper grain storage bin 19 for automatic control of feeding, which are commonly used in general grain dryers. Signals are sent through the positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com