Cross-beam punch

A technology for presses and upper beams, applied in forging presses, forging presses, manufacturing tools, etc., can solve problems such as unreliable lubrication monitoring of transmission systems, shutdown of peripheral equipment, and large power grid shocks, and achieves improved centralized monitoring and control capabilities. Machining accuracy, good use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing:

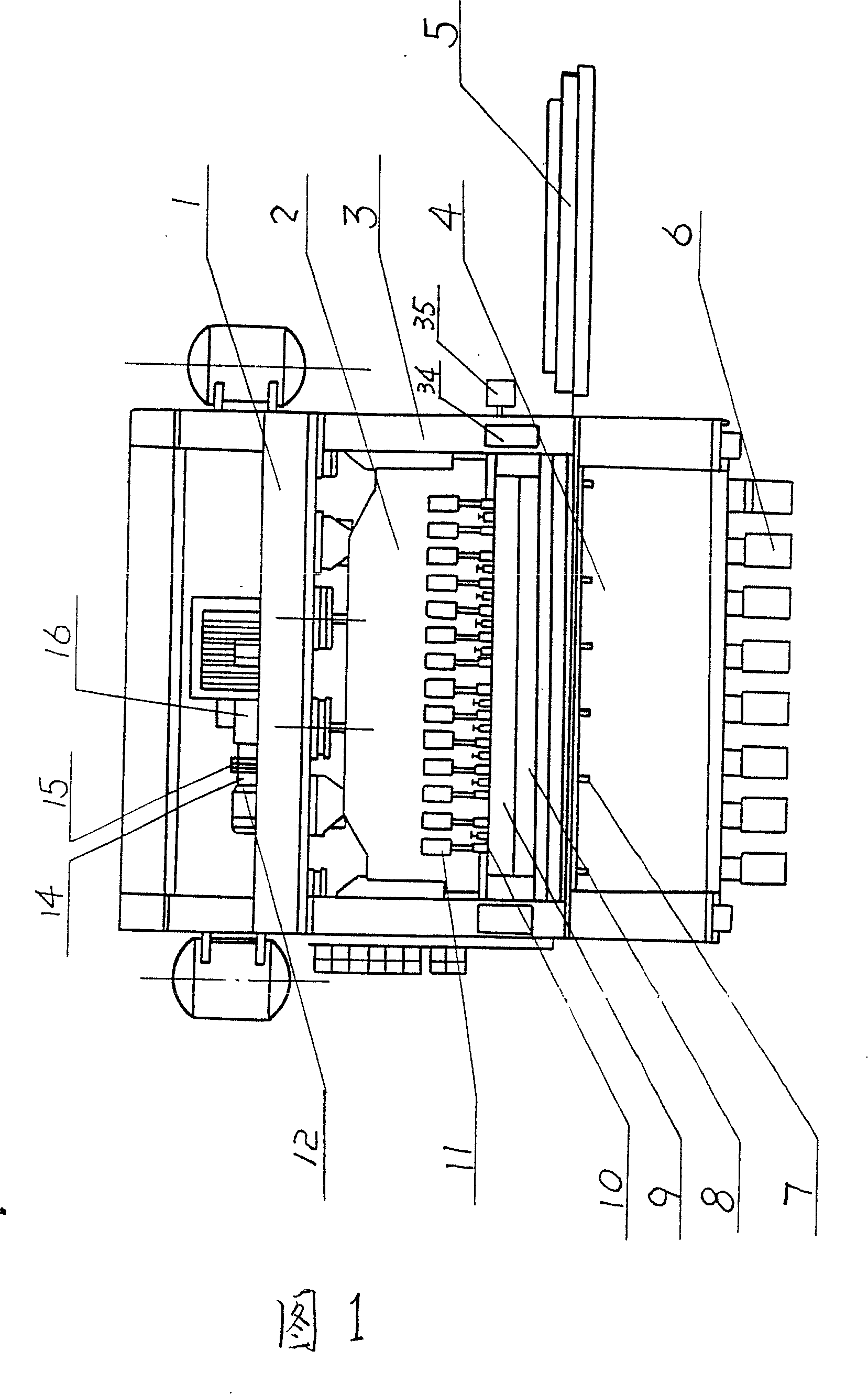

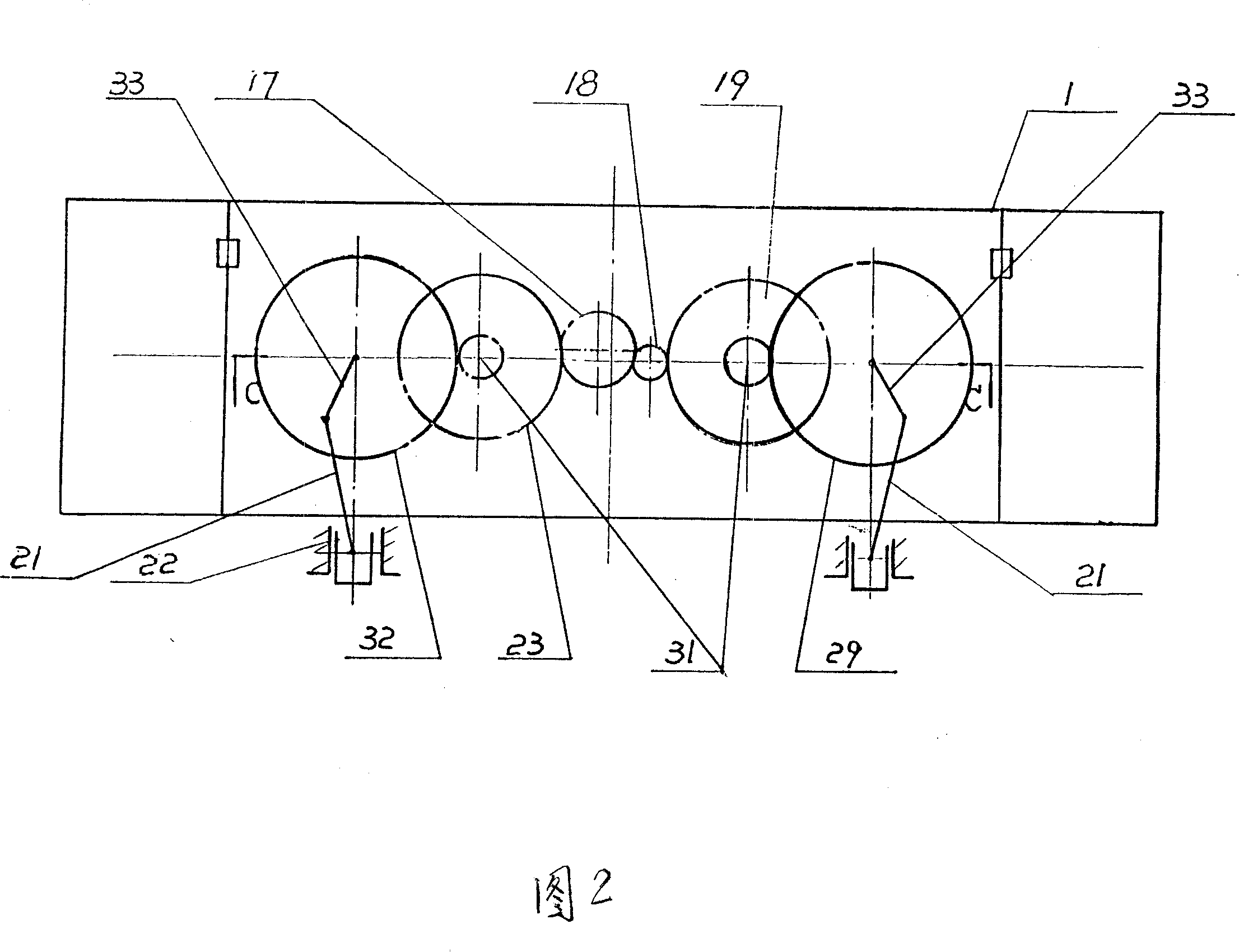

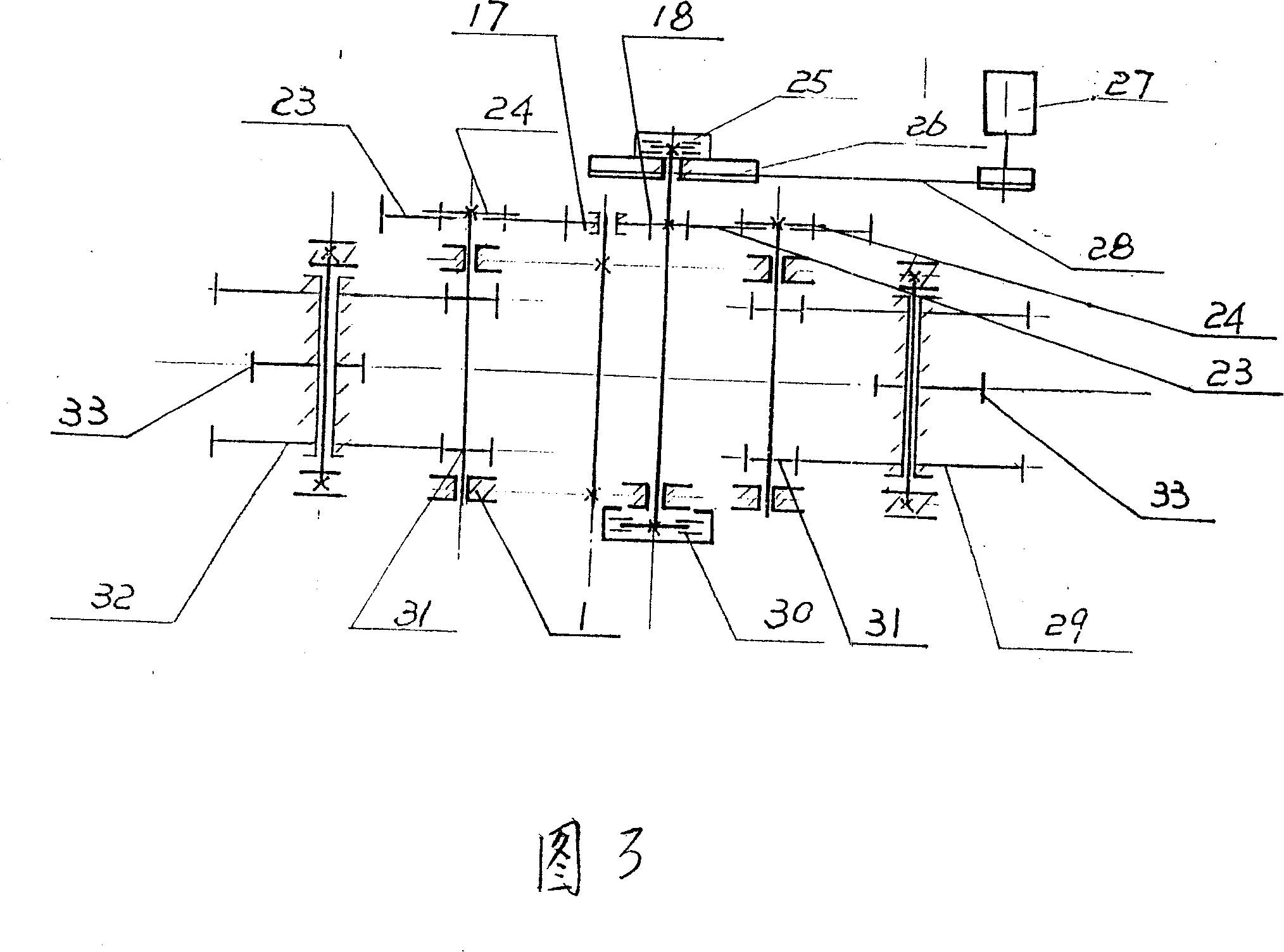

[0014] The invention is mainly composed of a press main body, a micro-motion device, a transmission system, a hydraulic system, a pneumatic system, a lubrication monitoring system and an electrical control system. As shown in Figure 1, the main body of the press is mainly composed of an upper beam 1, a slider 2, a column 3, a base 4, a mobile table 5, a stretching pad 6, a mobile table clamp 7, an upper mold clamp 10, Topping material 11 and so on are composed. The present invention is more than 17m long, more than 7m wide, more than 18m, and weighs more than 1500 tons. The upper beam 1 and the base 4 are respectively divided into three pieces according to a certain ratio, and they are assembled together with bolts and keys. The upper beam 1, the base 4 and the four columns 3 are pre-tightened by four tension bolts to form a rigid press frame. The slider 2 is located unde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com