Waterfree car washing type fresh maintenance agent and its preparation method

A curing agent and technology for car tires, applied in cleaning methods and appliances, chemical instruments and methods, cleaning methods using liquids, etc., can solve problems such as unstable performance of tire retreading curing agents, waste of water resources, etc., to achieve industrial production and environmental protection, saving resources, and saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

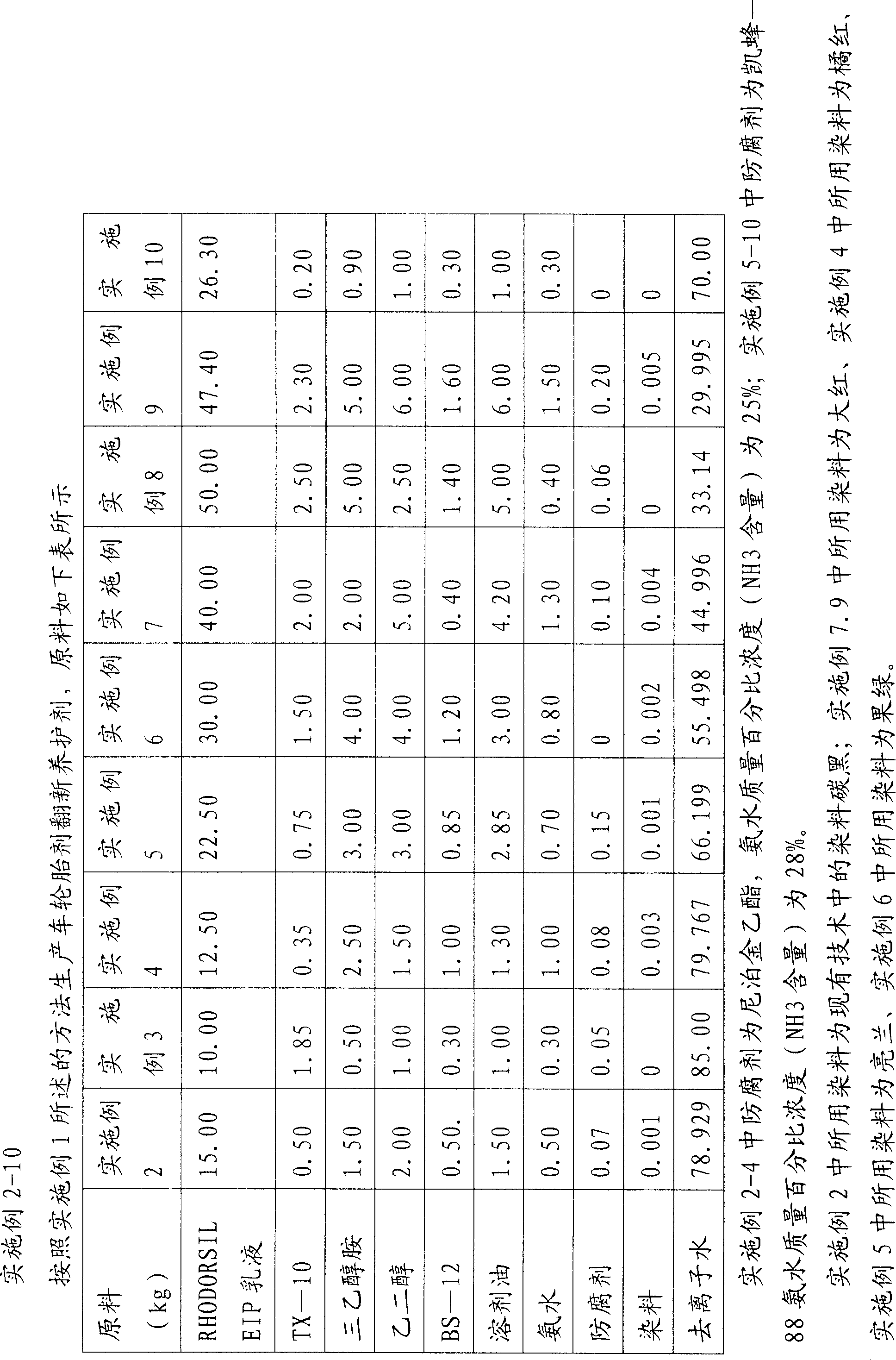

Examples

Embodiment 1

[0032] RHODORSIL EIP emulsion 27.08kg, TX-10 1.0kg, triethanolamine 2.05kg, ethylene glycol 2.5kg, BS-12 0.8kg, solvent oil 2.29kg, 20% ammonia water 0.68kg, methyl paraben 0.1kg , Cuilan 0.1kg, deionized water 63.5kg.

[0033] 1). Liquid A: Add deionized water into the stirring tank, and then add it in proportions under constant stirring, non-ionic surfactant, triethanolamine, ethylene glycol, BS-12;

[0034] 2). B liquid: a certain proportion of EIP emulsion, add the solvent oil under stirring;

[0035] 3). Under stirring, add the mixed B liquid to the above mixed A liquid, add ammonia water, methyl paraben, and finally add turquoise blue toning, mix evenly, and discharge the material, and package as required.

[0036]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com