Rope arranging speed reducing box on multilayer winding reel gear type rope arranging device

A reduction box and rope puller technology, which is applied in hoisting devices, clockwork mechanisms, gear transmissions, etc., can solve problems such as poor versatility and unsatisfactory reduction boxes, and achieve long life, simple and reliable work, and excellent manufacturing process. uncomplicated effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

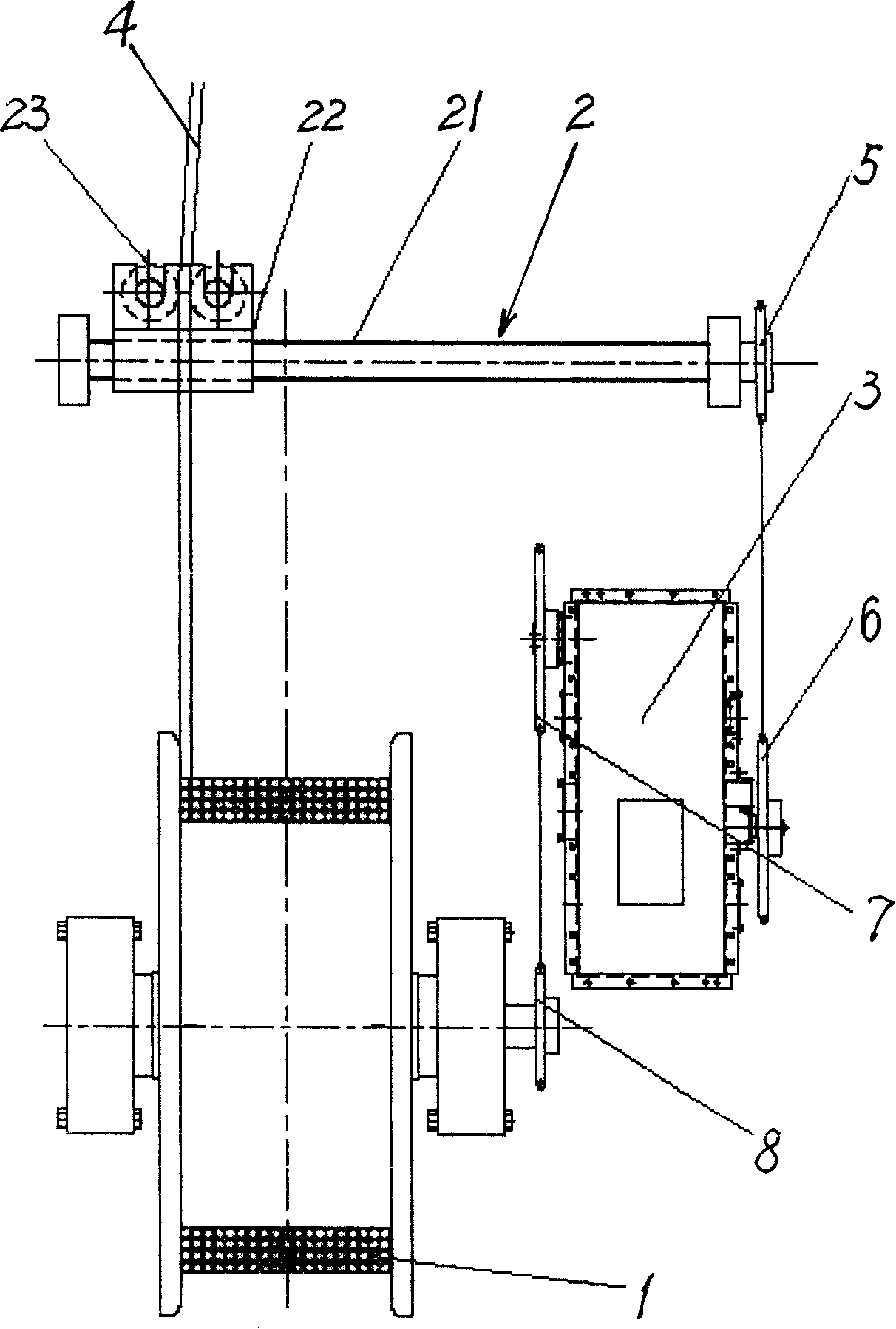

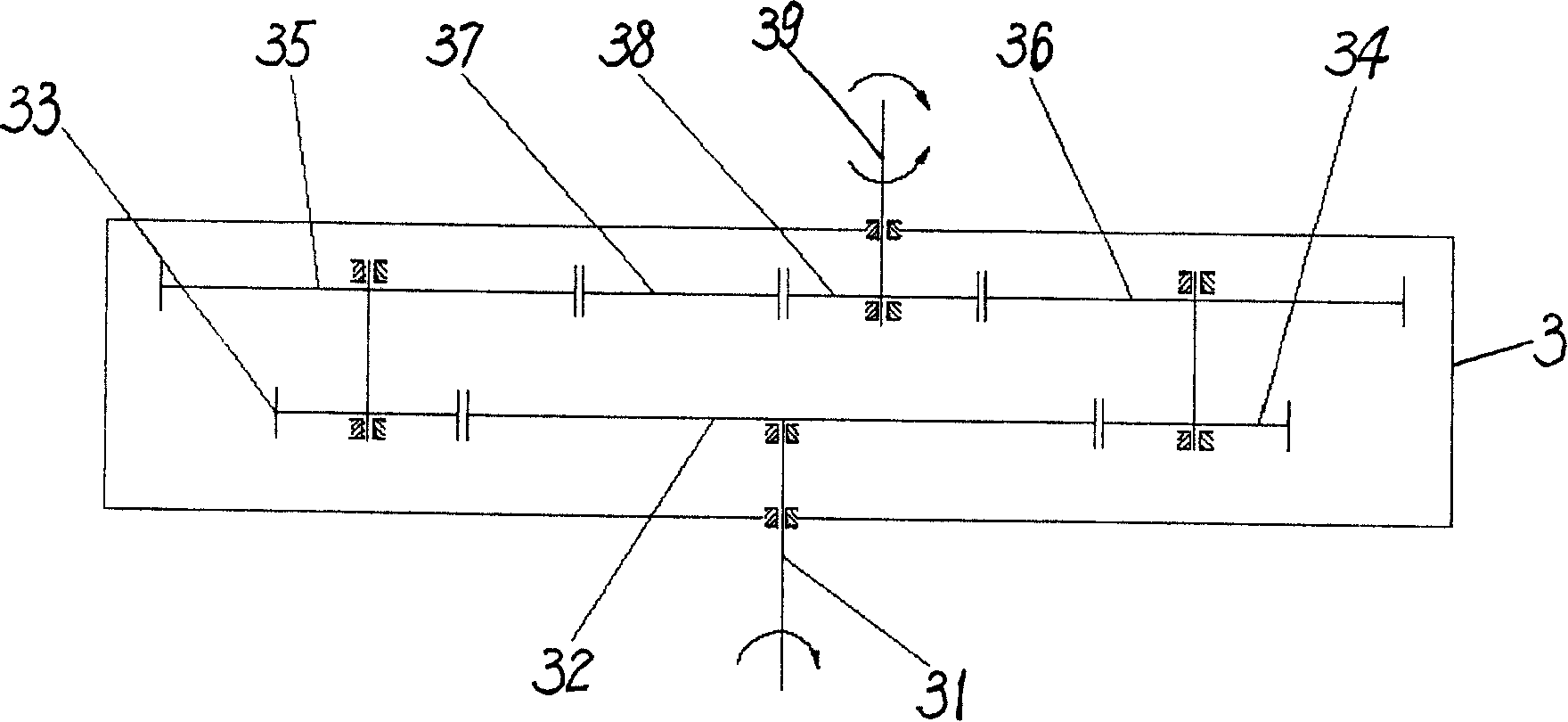

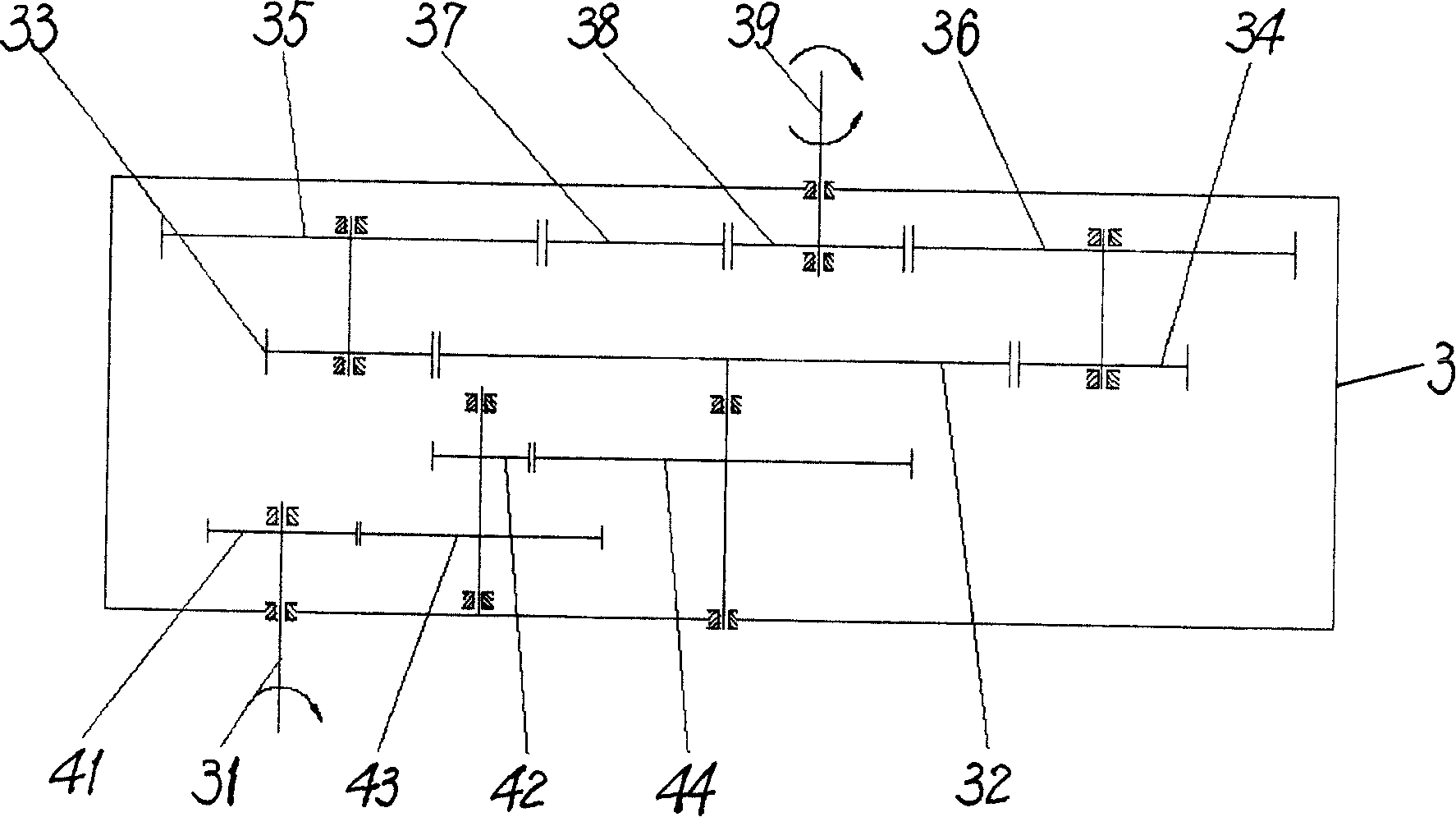

[0015] see figure 1 , A multi-layer winding reel toothed rope arranging device of the present invention includes a multi-layer winding reel 1, a screw device 2, a rope reduction gearbox 3 and a sprocket.

[0016] The screw device 2 is equipped with a screw rod 21, a nut 22, and an idler roller 23, and the idler roller 23 is installed on the nut 22 and moves along the axial direction of the screw rod along with the nut 22. The screw device 2 is installed in the rope outlet direction of the multi-layer winding drum 1, and the steel wire rope 4 drawn from the multi-layer winding drum 1 passes between the two supporting rollers 23 in the screw device 2, and is driven by the two supporting rollers. 23 clamping. The end of the screw device 2 is equipped with a first output sprocket 5 .

[0017] The rope reduction box 3 is installed between the screw device 2 and the reel 1 shaft. One end of the rope reduction box 3 is equipped with a second output sprocket 6, and the second outpu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com