Carried by CeO2 based composite oxides coated carrier Pd catalyst, its preparation method

A composite oxide and catalyst technology, which is applied in the direction of catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, etc. It can solve the problem of easy peeling off of the coating and poor thermal stability of the coating, etc. Problems, to achieve the effect of not easy to fall off, strong adhesion, thermal stability and anti-sintering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

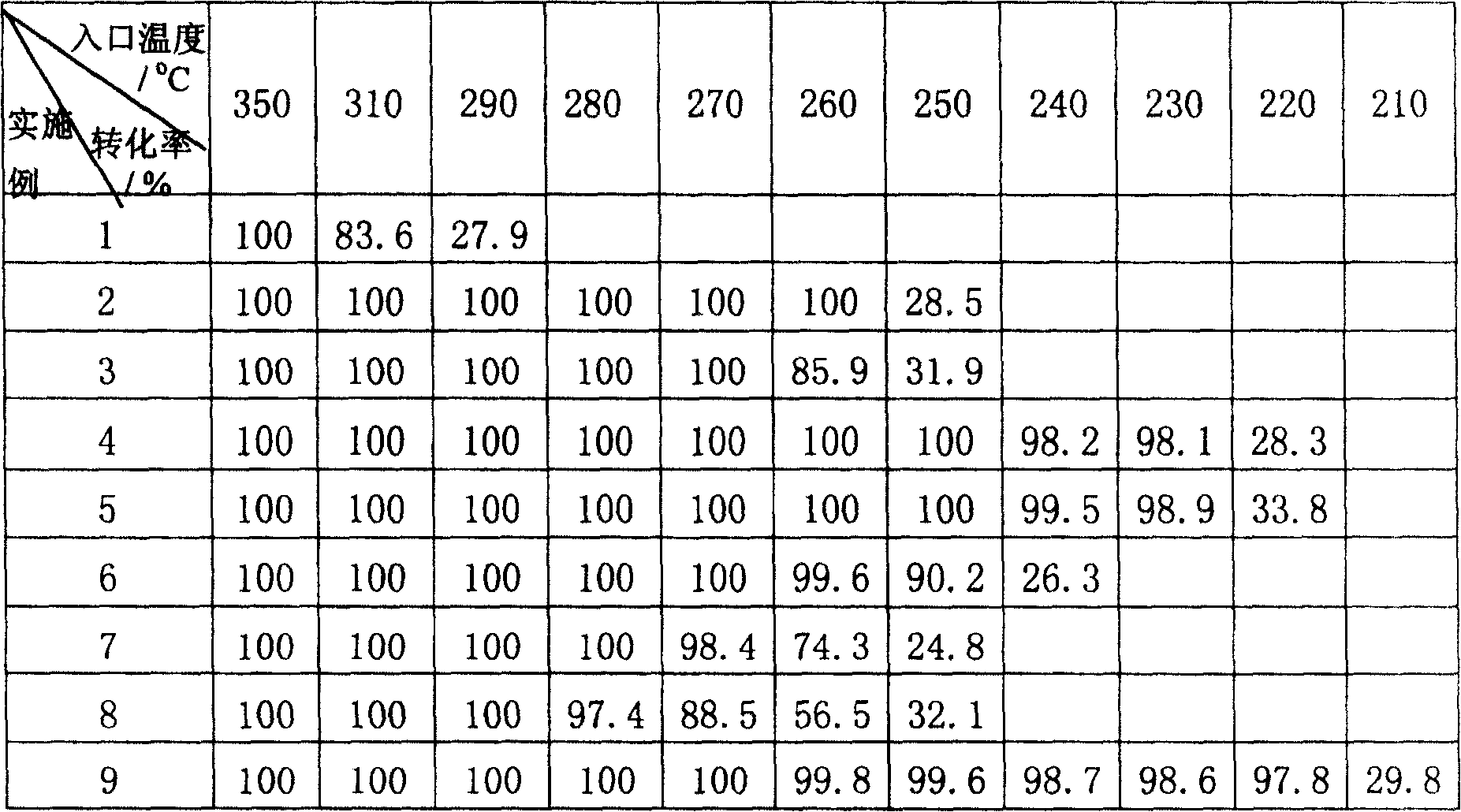

Examples

Embodiment 1

[0017] Weigh 10.67g Ce(NO 3 ) 3 ·6H 2 O and 7.98g citric acid, after mixing, add an appropriate amount of deionized water to dissolve to obtain a coating solution. The size is 50mm×25mm×40mm, and the opening rate is 195cell / in 2 , with a mass of 31.41g cordierite honeycomb ceramics immersed in the coating liquid, take it out, blow out the residual liquid in the honeycomb channel, at this time there is still part of the coating liquid remaining, air the cordierite honeycomb ceramics at room temperature to 50°C until the surface is dry, and then Dry at 120°C for 1 hour, then bake in a muffle furnace at 500°C for 1 hour. Repeat the above process 2 to 3 times until the coating solution is completely impregnated and adsorbed, and finally baked in a muffle furnace at 500 ° C for 4 hours to obtain CeO 2 coating.

[0018] The preparation concentration is the H of 8.9g Pd(1g / L) / L solution 2 PdCl 4 100mL of aqueous solution is used as the impregnation solution of precious metal a...

Embodiment 2

[0020] Weigh 0.57g Y 2 o 3 Join HNO 3 , with 9.16g Ce(NO 3 ) 3 ·6H 2 O and 5.35g of citric acid are mixed and added with an appropriate amount of deionized water, and stirred evenly to obtain a coating solution. The size is 50mm×25mm×40mm, and the opening rate is 195cell / in 2 , with a mass of 31.40g cordierite honeycomb ceramics immersed in the coating solution, take it out, blow out the residual liquid in the honeycomb channel, air the cordierite honeycomb ceramics at room temperature to 50°C until the surface is dry, then dry at 120°C for 1 hour, and then Baked in a furnace at 500°C for 1 hour. Repeat the above process 2 to 3 times until the coating solution is completely impregnated and adsorbed, and finally baked in a muffle furnace at 500 ° C for 4 hours to obtain Ce 0.8 Y 0.2 o 1.9 coating.

[0021] Measure 5.6mL H 2 PdCl 4 The aqueous solution is diluted with deionized water until the honeycomb ceramic carrier is just submerged, and then the coated honeycomb...

Embodiment 3

[0023] Weigh 0.98g Sm 2 o 3 Join HNO 3 , with 9.73g Ce(NO 3 ) 3 ·6H 2 O and 4.93g of citric acid are mixed and added with an appropriate amount of deionized water, and stirred evenly to obtain a coating solution. The size is 50mm×25mm×40mm, and the opening rate is 195cell / in 2 , with a mass of 31.23g cordierite honeycomb ceramics immersed in the coating solution, take it out, blow out the residual liquid in the honeycomb channel, air the cordierite honeycomb ceramics at room temperature to 50°C until the surface is dry, then dry at 120°C for 1 hour, and then Baked in a furnace at 500°C for 1 hour. Repeat the above process 2 to 3 times until the coating solution is completely impregnated and adsorbed, and finally baked in a muffle furnace at 500°C for 4 hours to produce Ce 0.8 SM 0.2 o 1.9 coating.

[0024] Measure 5.6mL H 2 PdCl 4 The aqueous solution is diluted with deionized water until the honeycomb ceramic carrier is just submerged, and then the coated honeycom...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com