Vane of aerater

An aerator and impeller technology, which is applied in the field of rotary brush aerator impellers, can solve the problems of broken brushes, increased costs, and high manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

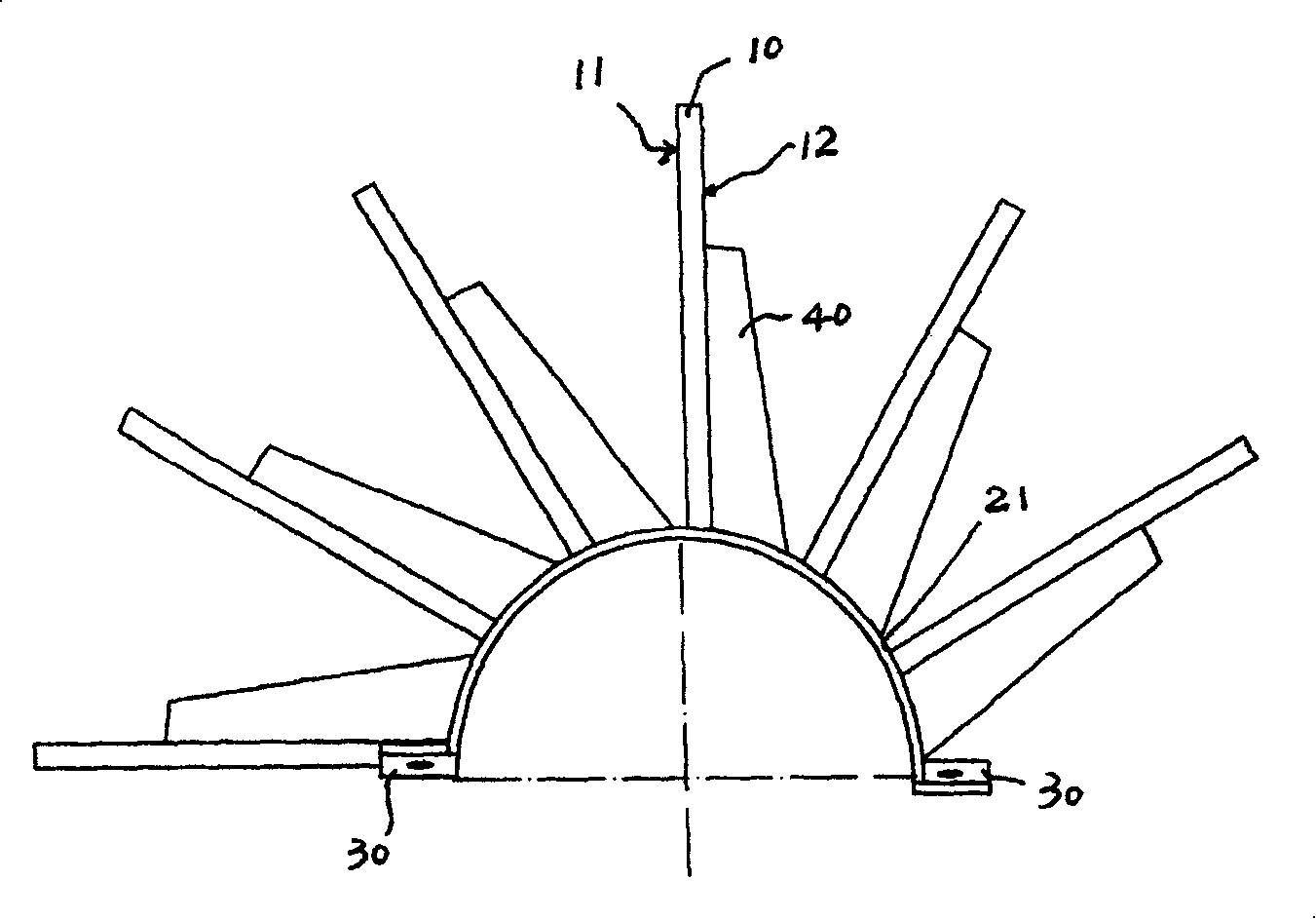

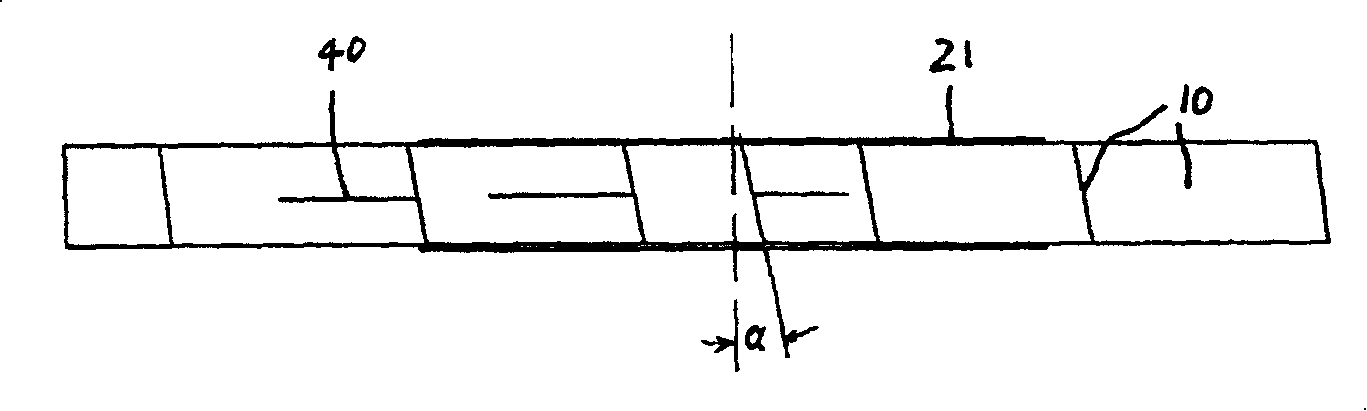

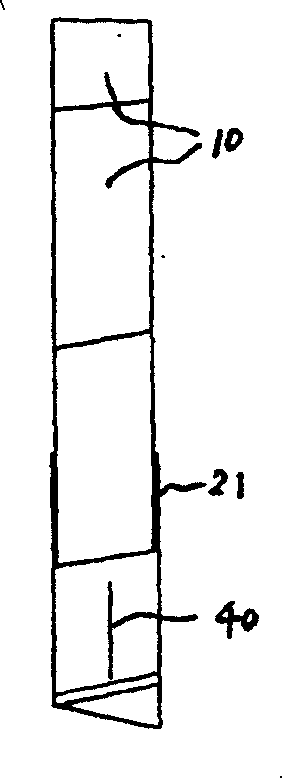

[0011] combine figure 1 , 2 , 3, the present invention adopts the form of a half impeller unit, and then combines to form a complete impeller assembly, and installs the impeller assembly on the main shaft of the rotating brush. The collar 20 , the brush piece 10 is welded and fixed on the outer surface of the collar unit 21 , and the head and tail of the half-shaft collar unit 21 are provided with a connecting plate 30 for connecting with another half-shaft collar unit 21 . There can be 2 to 4 half-shaft collar units 21, and the two-half structure is a more preferred form, that is, the impeller is composed of two independent half-shaft collar units 21 and the The half impeller unit composed of the brush slices 10 is combined, and the connecting plate 30 is connected by bolts. A rib plate 40 is provided between the backwater surface 12 of the brush piece 10 and the half shaft collar unit 21 . With the above structure, the phenomenon of stress concentration at the root of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com