Electric tuning integrated optical filter with high-fineness

An optical filter and electrical tuning technology, applied in the coupling of optical waveguides, electromagnetic wave transmission systems, optics, etc., can solve the problems of slow electro-optical tuning filters, low spectral precision, large insertion loss, etc., and achieve spectral adjustment. Wide range, high spectral finesse, and easy-to-integrate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

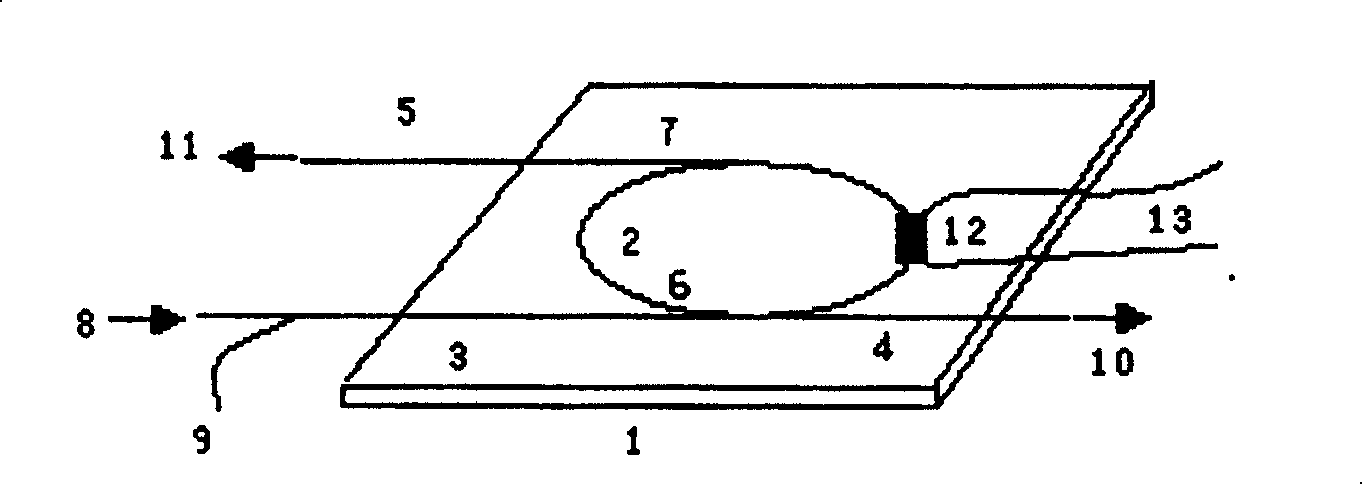

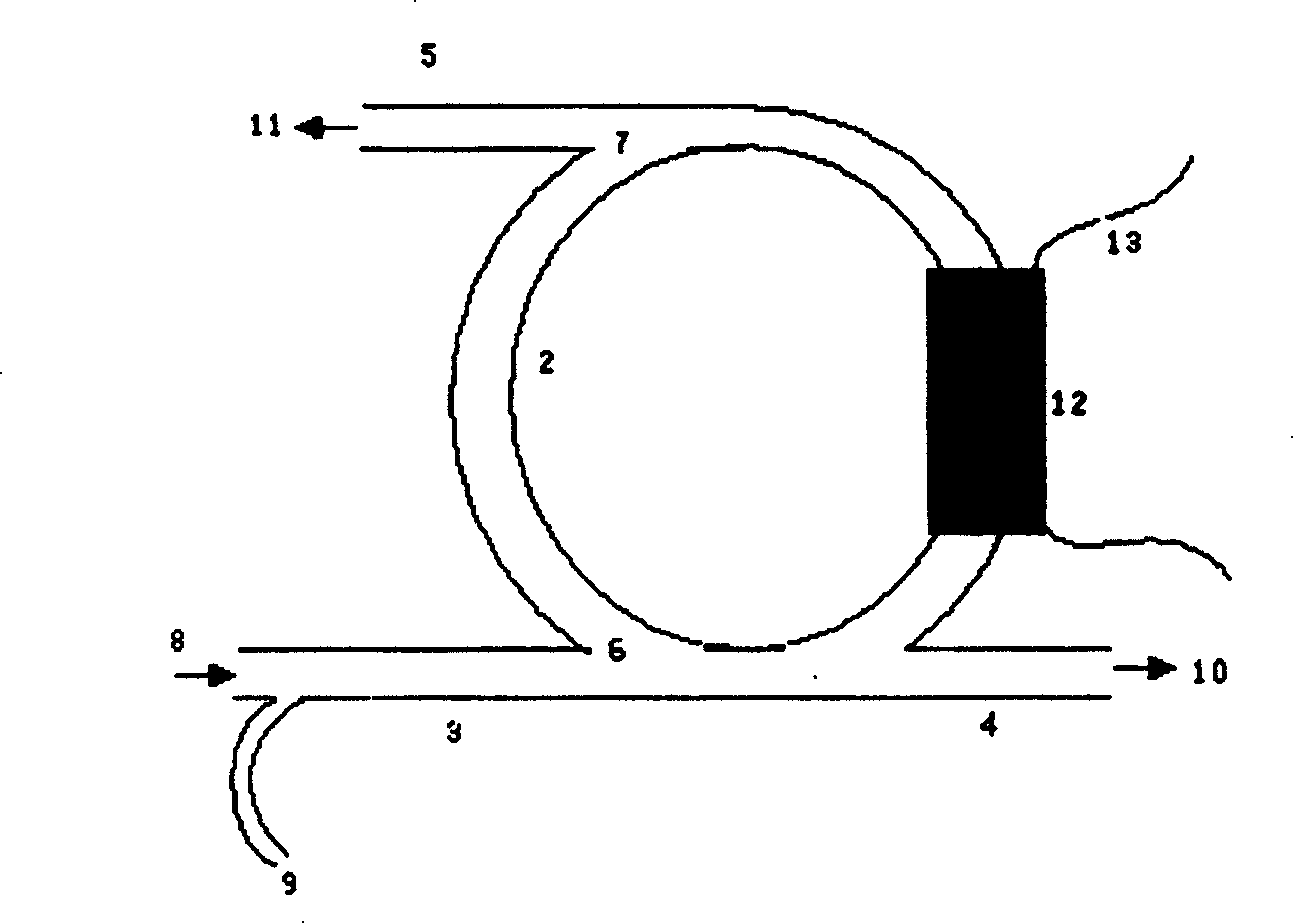

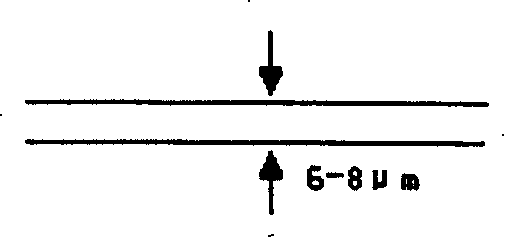

[0035] Selection: Straight waveguides 3, 4, 5 are 6-8 μm wide and 1-1.5 cm long; the refractive index of annular cavity 2 is about 1.5; the ellipse length of ring waveguide cross section is 6-8 μm, and the ellipse width is 4 μm; signal distribution in straight waveguide 1 The ratio to the straight waveguide 2 and the ring waveguide 3 is 5:95; the thickness of the heating resistor is 1 μm; the lead wire of the heating electrode is formed by pressure welding of gold wire or aluminum wire. According to the technical scheme of the present invention, a high-precision electronically tunable integrated optical filter is formed. After use, it can be known that the high-precision electronically tunable integrated optical filter provided by the present invention can achieve spectral fineness (kHz level).

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com