Valve control type lead acid accumulator for metro vehicle

A lead-acid battery, valve-controlled technology, applied in the direction of lead-acid battery, lead-acid battery electrode, lead-acid battery construction, etc., can solve the problems of high price, high cost of alkaline nickel-cadmium battery, high operating cost, etc., to achieve thermal Effects of runaway phenomenon control, weight and volume reduction, and island avoidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] specific implementation

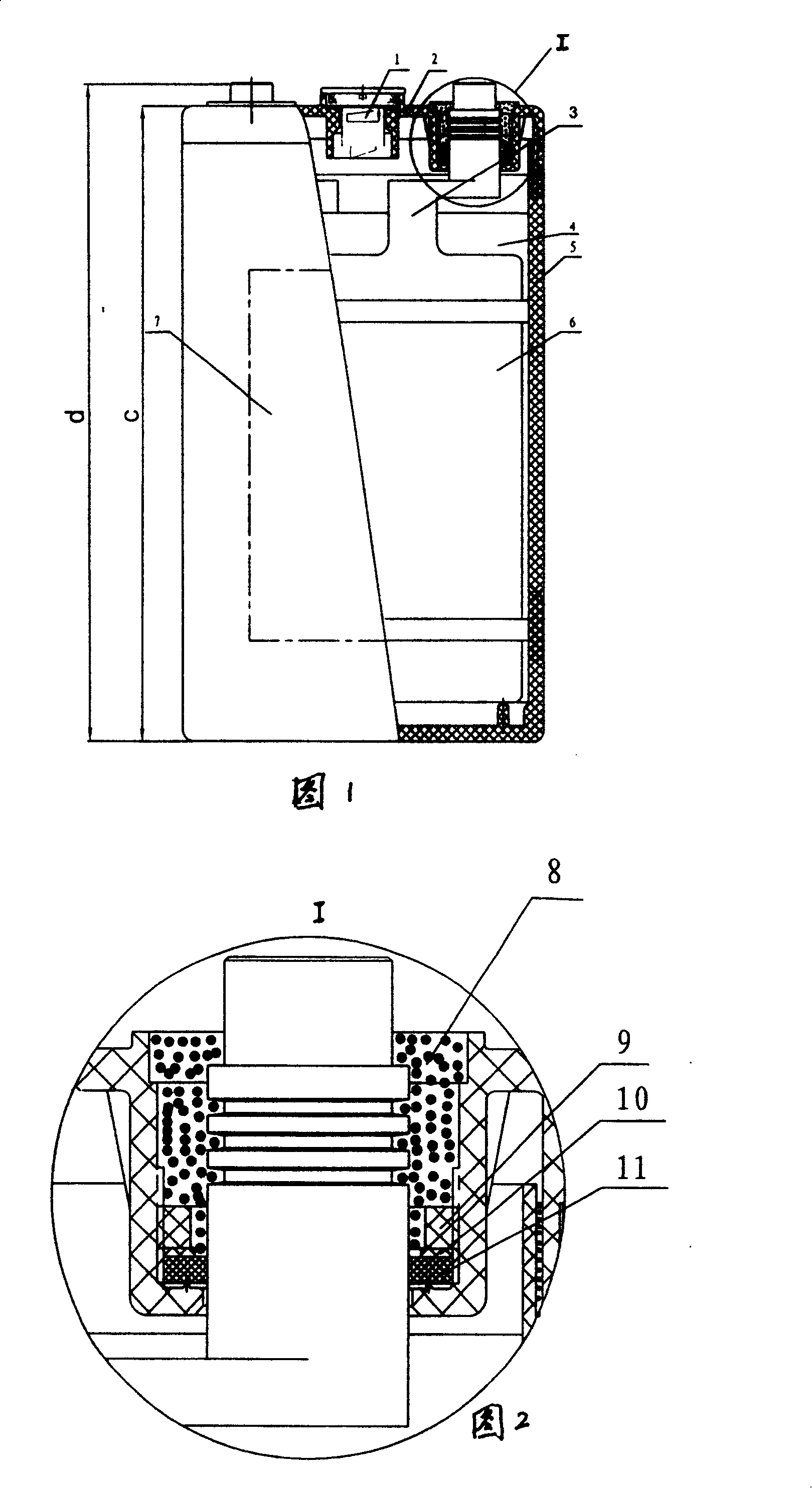

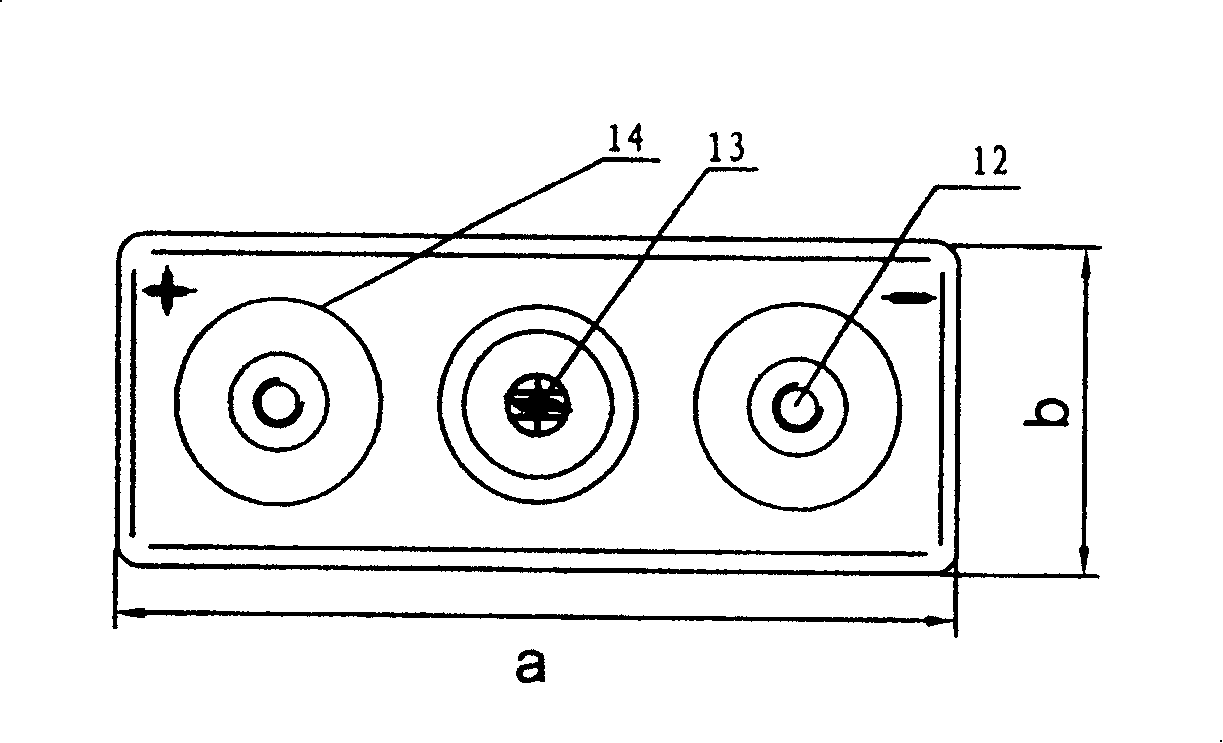

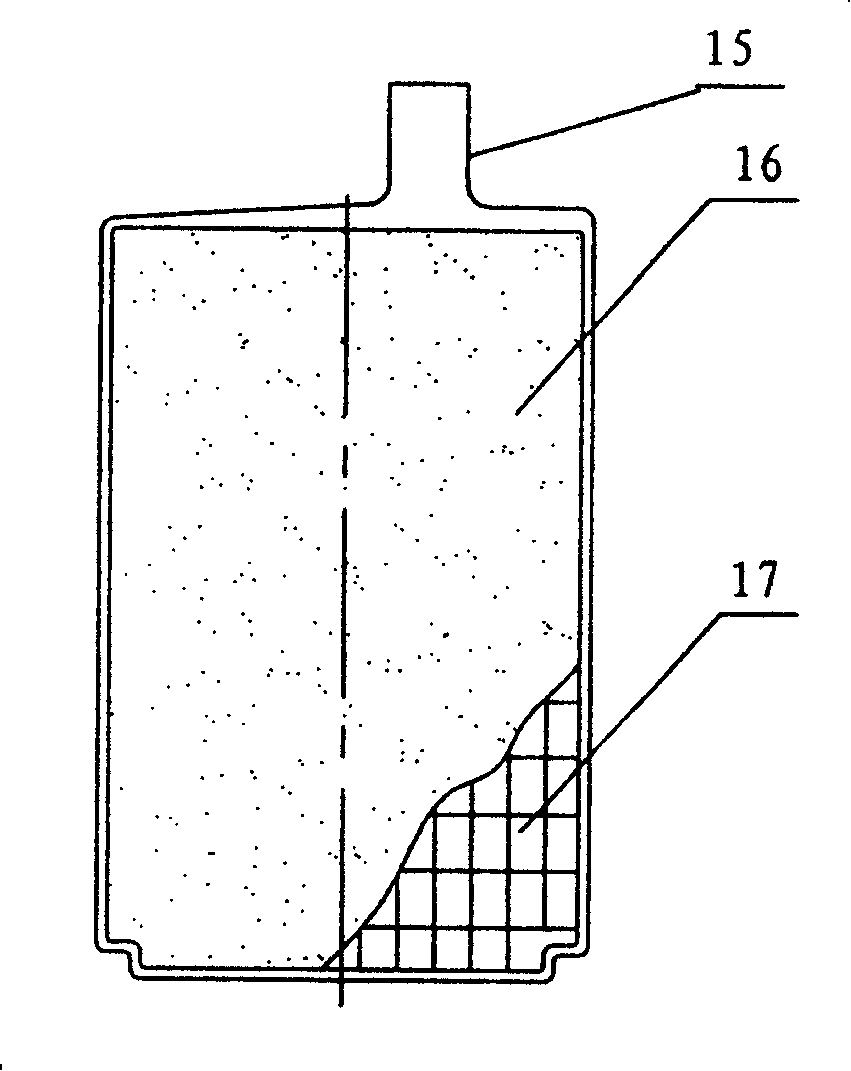

[0017] Referring to Figures 1-4, the present invention is composed of battery tank 5, battery cover 2, positive and negative plates 6, glass fiber separator 7, colloidal electrolyte 4, safety explosion-proof valve 1, battery lead-out terminal 12 and bus bar 3, etc. The above-mentioned positive and negative plates 6 are separated by glass fiber separators 7, which are sequentially stacked and then placed in the battery tank 5 under pressure. All flame-retardant ABS engineering plastics are used, the seal between the tank covers is bonded by heat sealing, and the battery lead-out terminal 12 and the battery cover 2 are double-sealed: that is, the bottom layer uses plastic nuts 9 and is pressed tightly through plastic gaskets 10 Acid-resistant and aging-resistant silicone fluororubber sealing ring 11, the upper layer is sealed with epoxy resin terminal glue 8. The colloidal electrolyte 4 is perfused in the battery tank, and the safety explosion-p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com