Integrated nonpowered hydraulic circular purifier

A hydraulic circulation and purification device technology, applied in the field of water treatment, can solve the problems of small size, high treatment efficiency, high operating cost, etc., and achieve the effect of compact structure, high treatment efficiency and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

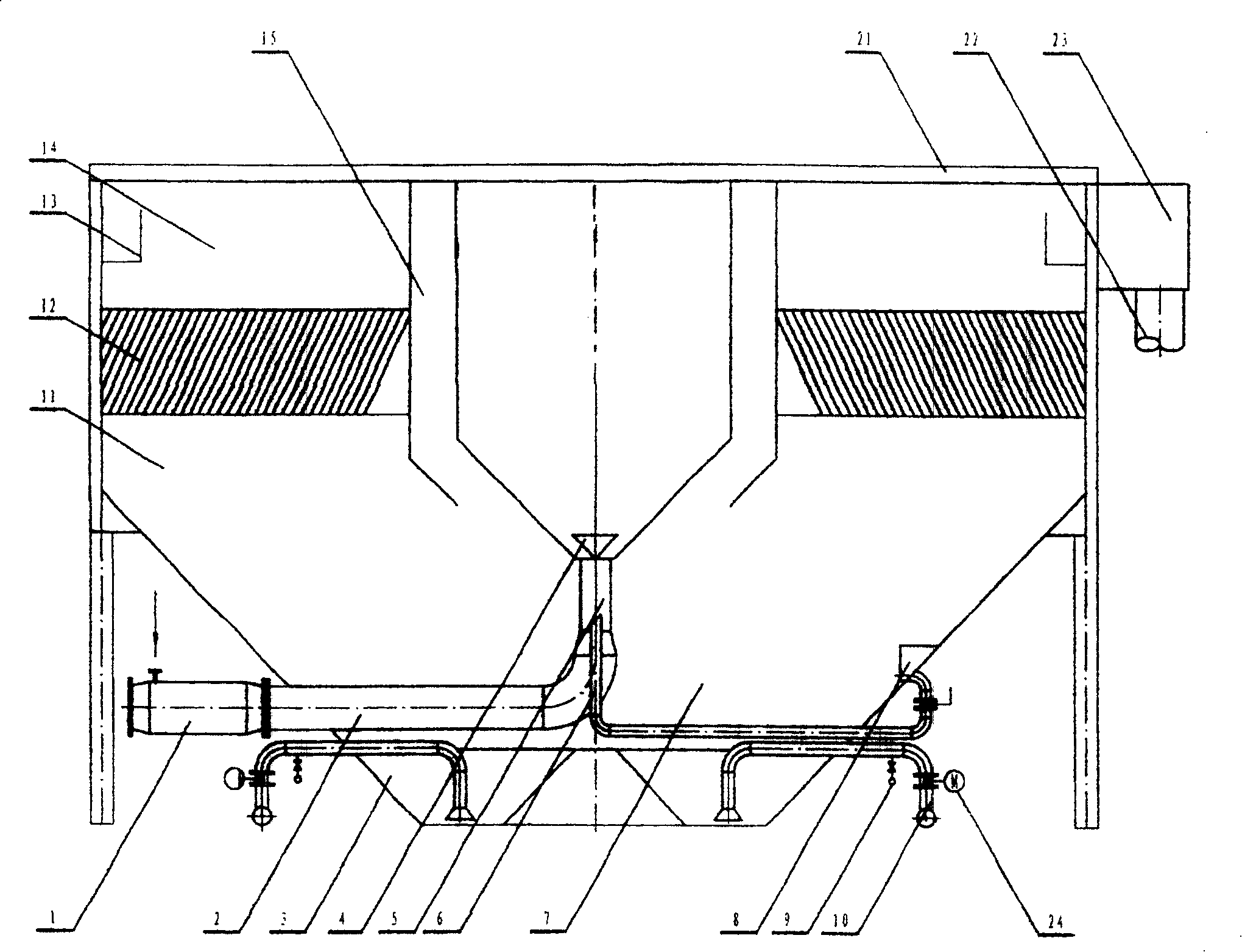

[0008] Embodiment 1, an integrated non-powered hydraulic circulation purification device, the bottom of the body (21) is a multi-bucket mud collection chamber (3), and an adjustable multi-point siphon mud discharge system (10) and a pressure water flushing system (9) are installed inside. , the electric valve (24) of the adjustable multi-point siphon sludge discharge system is connected with the signal of the electric control system to set the sludge discharge cycle; the flocculation mixing chamber (1) and its connecting pipe (2) and the sludge return pipe (6) are respectively It is arranged on both sides above the multi-bucket mud collection chamber (3) and is connected to the middle variable-diameter pressure-bearing acceleration tube (5). The cone bottom of the reaction chamber (16); the bottom of the flocculation reaction chamber (16) and the surrounding of the variable-diameter pressure-bearing acceleration tube (5) are sludge settling chambers (7) connected to the multi-b...

Embodiment 2

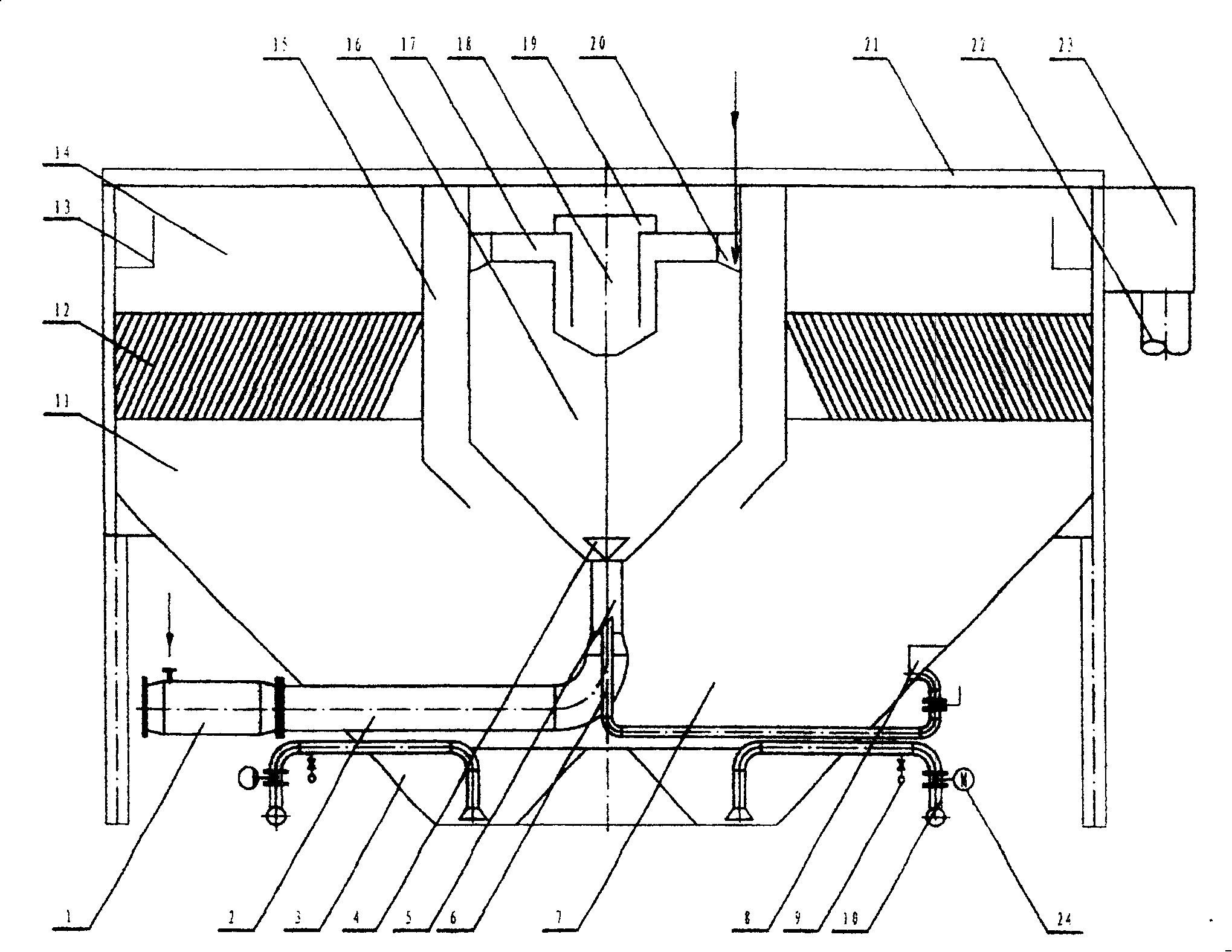

[0009] Embodiment 2, an integrated non-powered hydraulic circulation purification device, the bottom of the body (21) is a multi-bucket mud collection chamber (3), and an adjustable multi-point siphon mud discharge system (10) and a pressure water flushing system (9) are installed inside. , the electric valve (24) of the adjustable multi-point siphon sludge discharge system is connected with the signal of the electric control system to set the sludge discharge cycle; the flocculation mixing chamber (1) and its connecting pipe (2) and the sludge return pipe (6) are respectively The bottom of the sludge settling chamber arranged above the multi-bucket mud collecting chamber (3) is connected to the middle variable-diameter pressure-bearing acceleration tube (5), and the other end of the variable-diameter pressure-bearing acceleration tube (5) passes through the water flow uniform distributor (4 ) is connected to the cone bottom of the flocculation reaction chamber (16); the bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com