High crystallinity modified Y zeolite and its preparation method

A technology with high crystallinity and relative crystallinity, applied in the direction of crystalline aluminosilicate zeolite, octahedral crystalline aluminosilicate zeolite, chemical instruments and methods, etc., can solve zeolite structural damage, low cracking activity, and zeolite crystallinity decrease And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

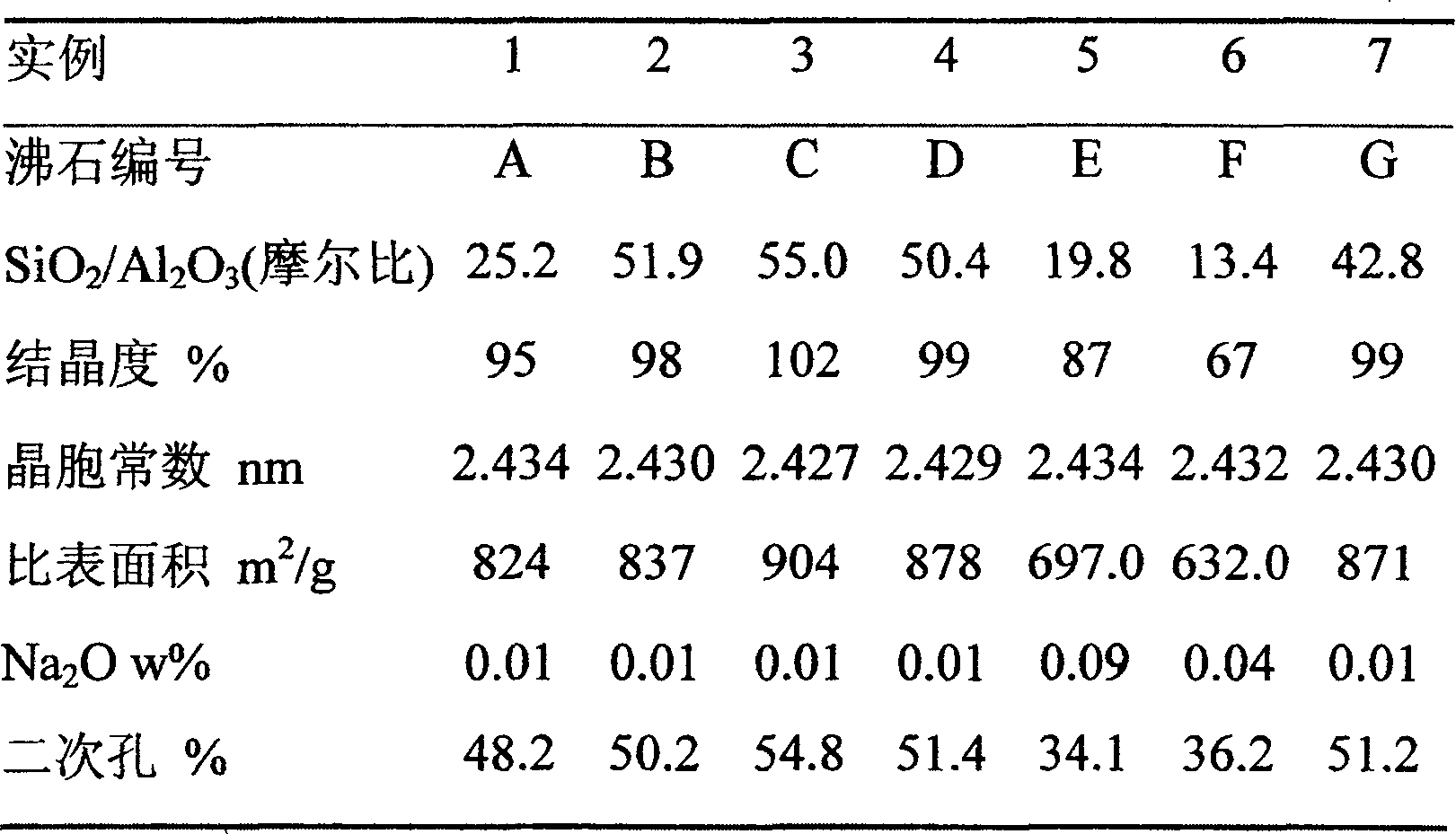

Examples

example 1

[0021] (1) Add 160kg of industrial NH to the exchange tank 4 NO 3 (Liaoyang Petrochemical Company product, purity>99.5%) and 910kg deionized water, then add 100kg NaY zeolite (Wenzhou Catalyst Factory produces, crystallinity is 100%, unit cell constant is 2.470nm, SiO 2 / Al 2 o 3 Molar ratio is 5.1, Na 2 O content is 12.0w%), the temperature is raised to 90 ° C, exchanged for 1.0 hour under stirring conditions, filtered, repeated exchanged 2 times, the filter cake is washed to neutral, dried to obtain Na 2 NH with an O content of 2.2w% 4 NaY zeolite.

[0022] (2), take NH 4 1.0kg of NaY zeolite was placed in a heat treatment furnace, and the temperature was raised to 600°C in 1.5 hours, and treated at 600°C and 0.15MPa steam pressure for 2.0 hours, and the sample was taken out after cooling down.

[0023] (3) Take 500 g of the zeolite sample after the first heat treatment and contact it with 5.0 L of 1.5 mol / L ammonium chloride solution, adjust the pH of the slurry to 6...

example 2

[0027] Get the NH obtained in step 1 in Example 1 4 300g of NaY zeolite (calculated on a dry basis) was placed in a heat treatment furnace at 600°C, and water vapor (100g / h) was injected to maintain the system pressure at 0.08MPa for 3.0 hours; then the sample was treated with 2mol / L NH 4 NO 3 Solution 3.0L contacted with HNO 3 Adjust the pH of the slurry to 4.8, and stir and exchange at 95°C for 1.0 hour, repeat the exchange 2 times, and wash; put the wet filter cake into a heat treatment furnace, and hydrothermally treat it at 700°C and 0.15MPa for 3.0 hours; the final sample is heated with 0.6 3.0L of mol / L HCl was dealuminated at 60°C for 1.5 hours to obtain product B. The physical and chemical properties of product B are listed in Table 1.

example 3

[0029] Get the NH obtained in step 1 in Example 1 4 500g of NaY zeolite (calculated on a dry basis) was placed in a heat treatment furnace and treated for 2.0 hours at 640°C with its own water vapor pressure of 0.1MPa. The sample was treated with 2mol / L NH 4 Exchange 2.5L of Cl solution, adjust the pH of the slurry to 5.8 with HCl before the exchange, and repeat the exchange 3 times. The filter cake is hydrothermally treated at 660°C and 0.1MPa for 5.0 hours, and the sample after hydrothermal treatment is treated with 0.2mol / L HCl 5.0 L of the solution was treated twice at 90° C. for 1.5 hours each time, filtered with suction, the filter cake was washed with distilled water, and dried to obtain product C. The physical and chemical properties of product C are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| Bronsted acidity | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com