Comber controlling system with industrial bus

An industrial bus and control system technology, which is applied in the direction of wired transmission system, general control system, control/regulation system, etc., can solve the problem of not being able to quickly and conveniently switch the separation roller, and not being able to change the speed of the master-slave motor efficiently, accurately and intuitively. Ratio and other issues, to achieve the effect of high data exchange speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

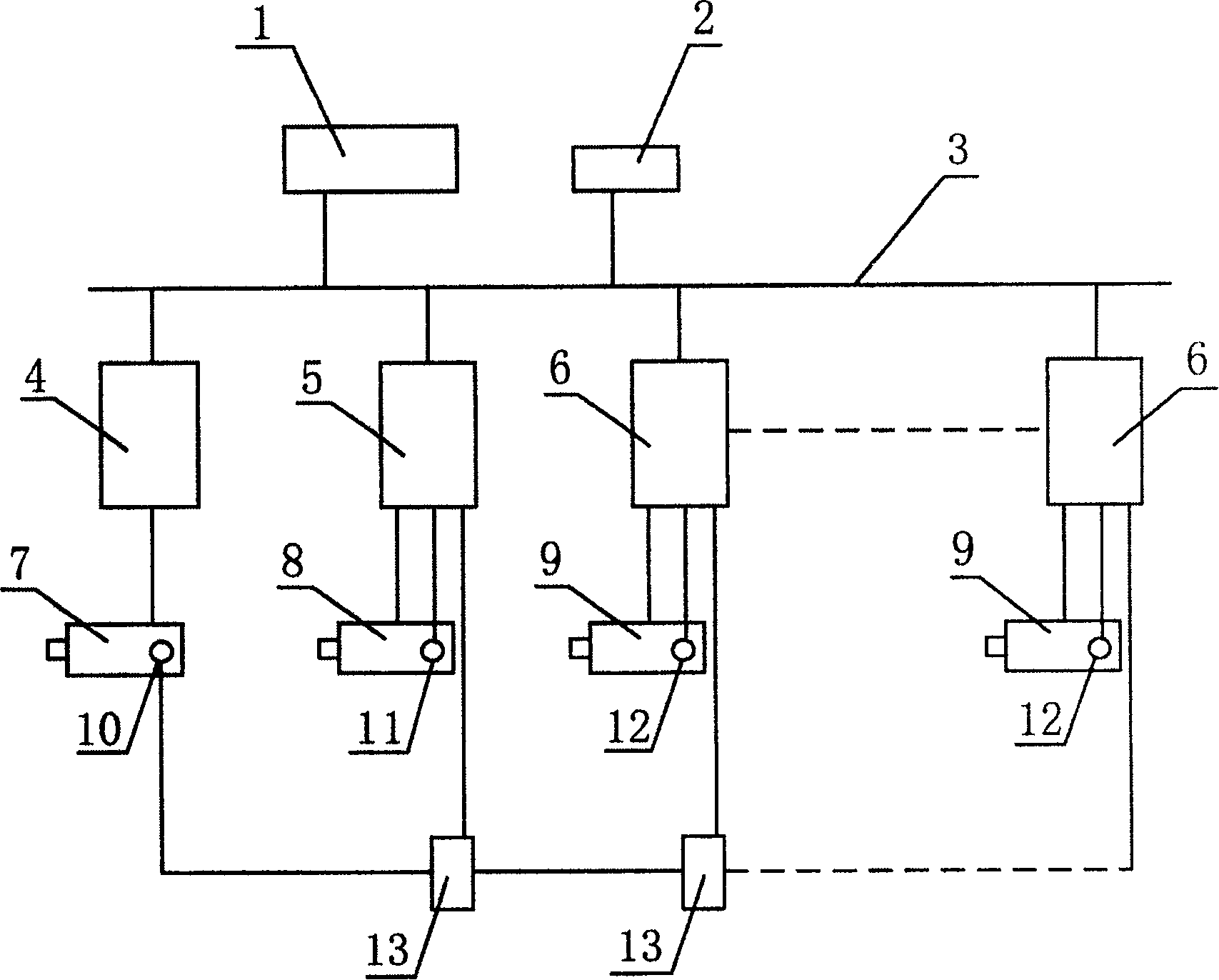

[0018] Such as figure 1 The shown combing machine control system with industrial bus is composed of a control device, a drive device, and an industrial bus system 3. The control device is composed of a host computer 1, a man-machine interface 2, various sampling components and an expander 13. Various sampling elements are encoders 10 , 11 , 12 .

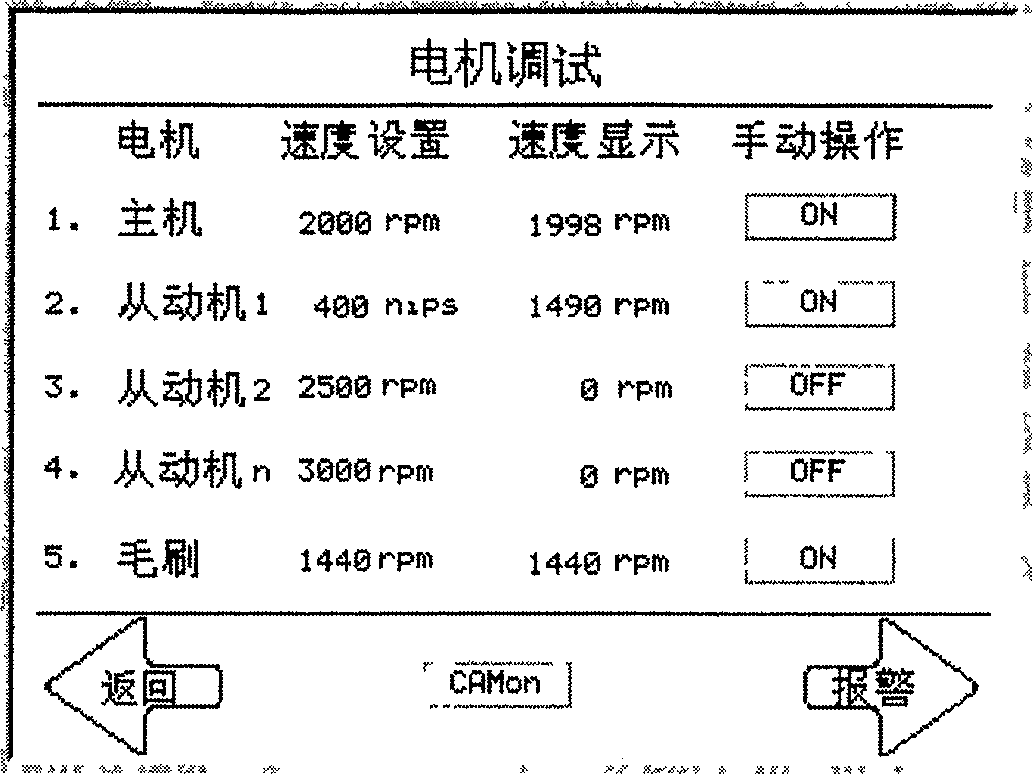

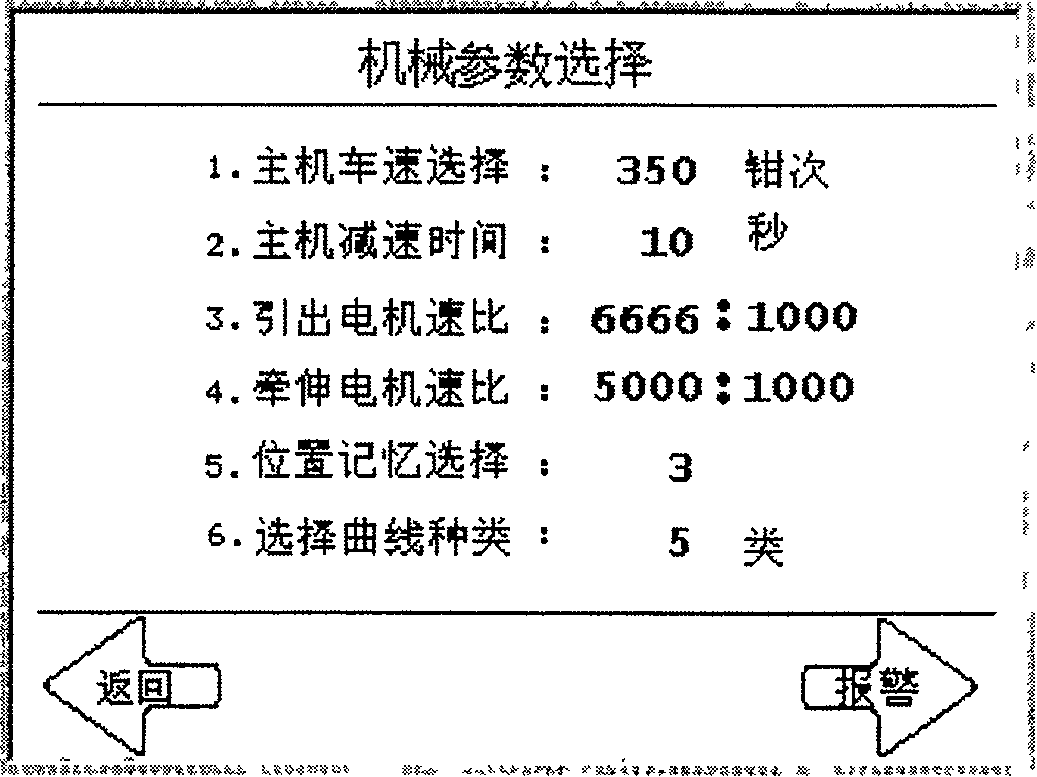

[0019] The man-machine interface 2 includes three screens, respectively reflecting the motor debugging, mechanical parameter selection, and the main screen.

[0020] The upper computer 1 is composed of a programmable computer controller (PCC controller for short) or a programmable controller (PLC controller for short) with a bus communication interface.

[0021] The man-machine interface 2 is a control / operation screen with a bus communication interface.

[0022] The driving device is composed of a master frequency converter 4 , a slave frequency converter 6 , a servo driver 5 , variable frequency motors 7 and 9 and a servo motor 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com