Negative electrode active material and its making method, negative electrode and nonaqueous electrolyte battery

A manufacturing method and a negative electrode technology are applied in the field of invention of non-aqueous electrolyte batteries to achieve the effects of good cycle charge and discharge performance, excellent industrial process, and good charge and discharge performance

Inactive Publication Date: 2008-09-03

GS YUASA INT LTD

View PDF4 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, there have been no previous reports on the use of the aforementioned phase-separated silicon oxides as anode active materials for nonaqueous electrolyte batteries.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0077] The nonaqueous electrolyte battery having the negative electrode active material of the present invention will be described in more detail based on the following examples. However, the present invention is not limited to the following examples.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Login to View More

Abstract

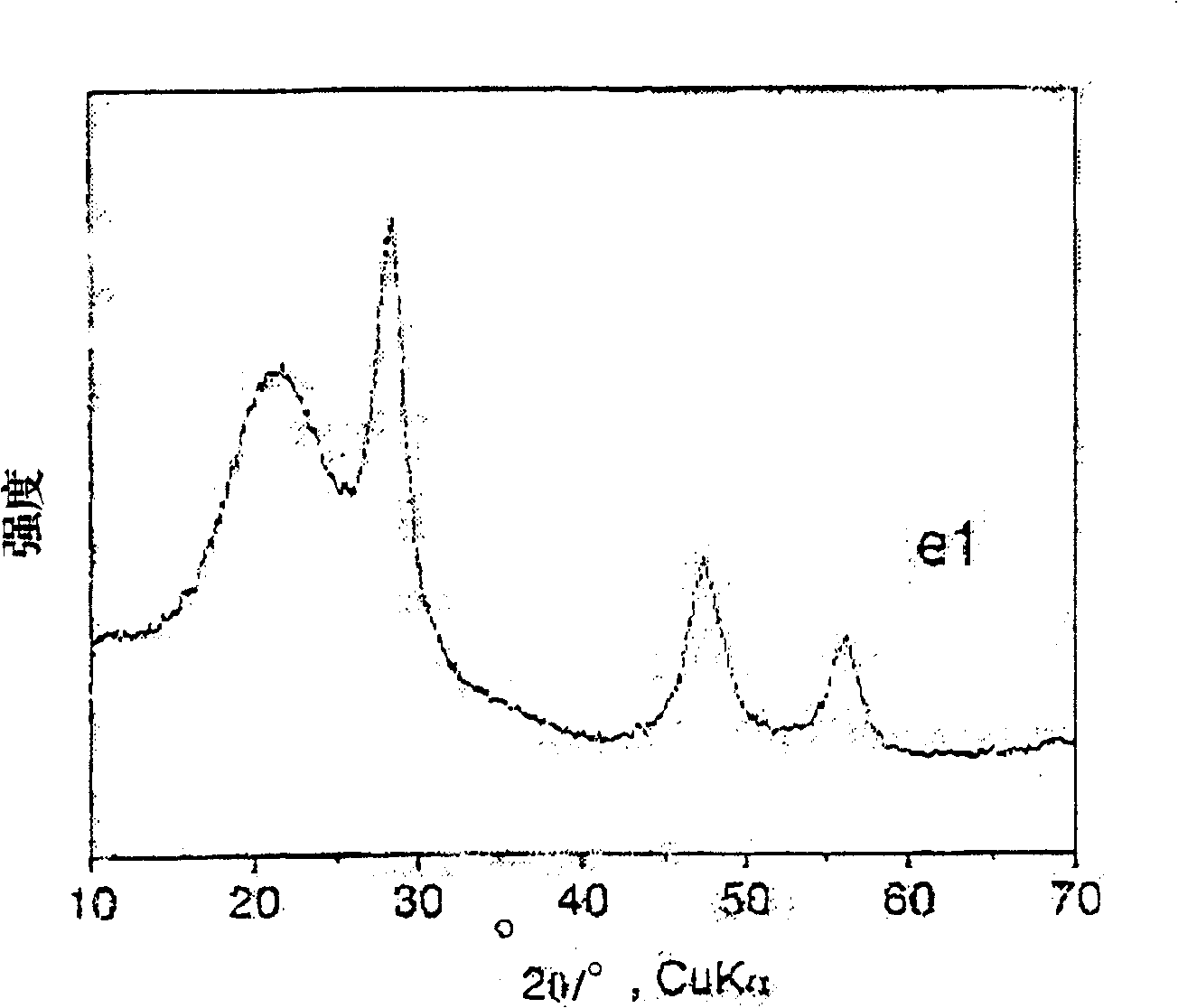

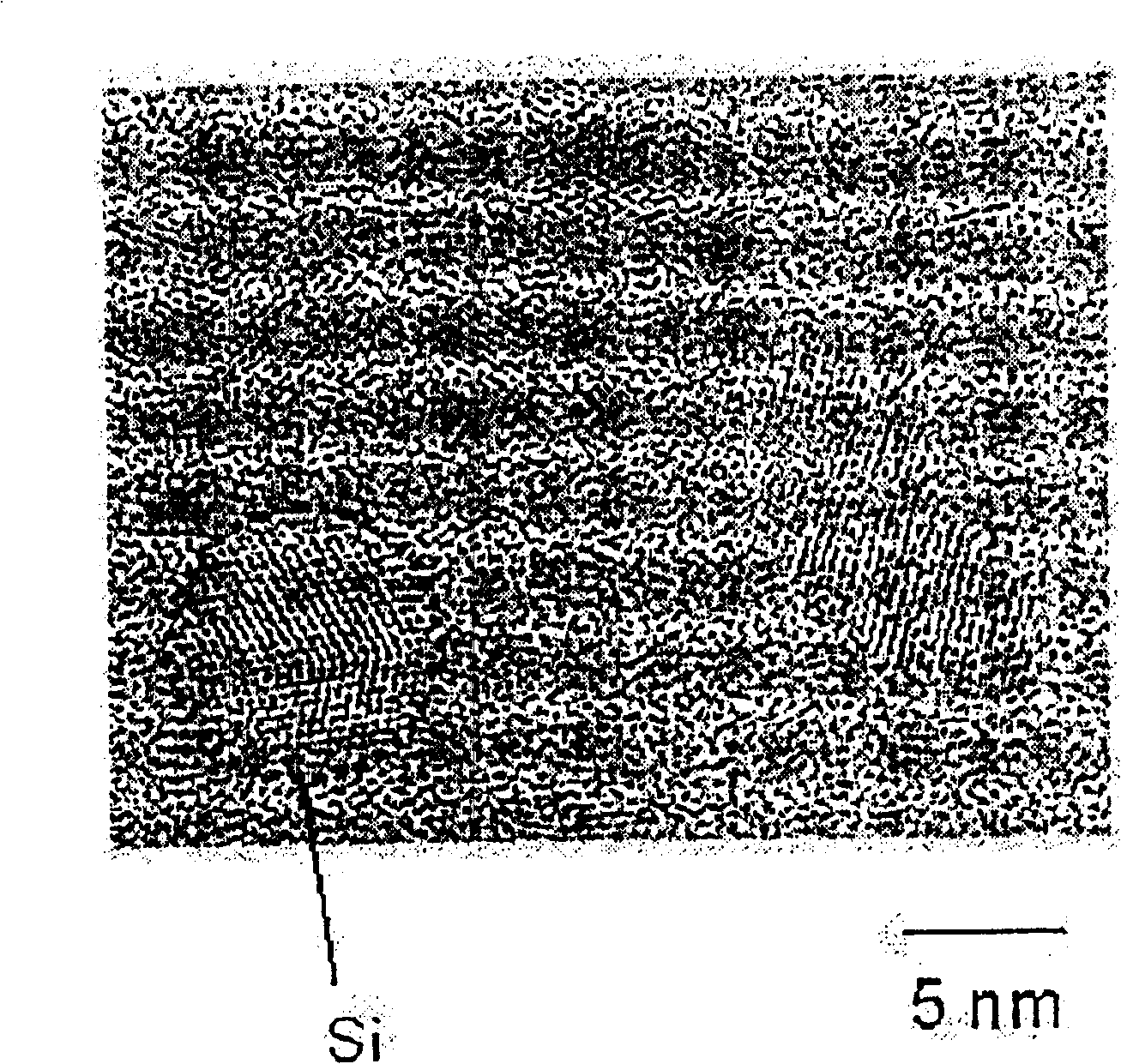

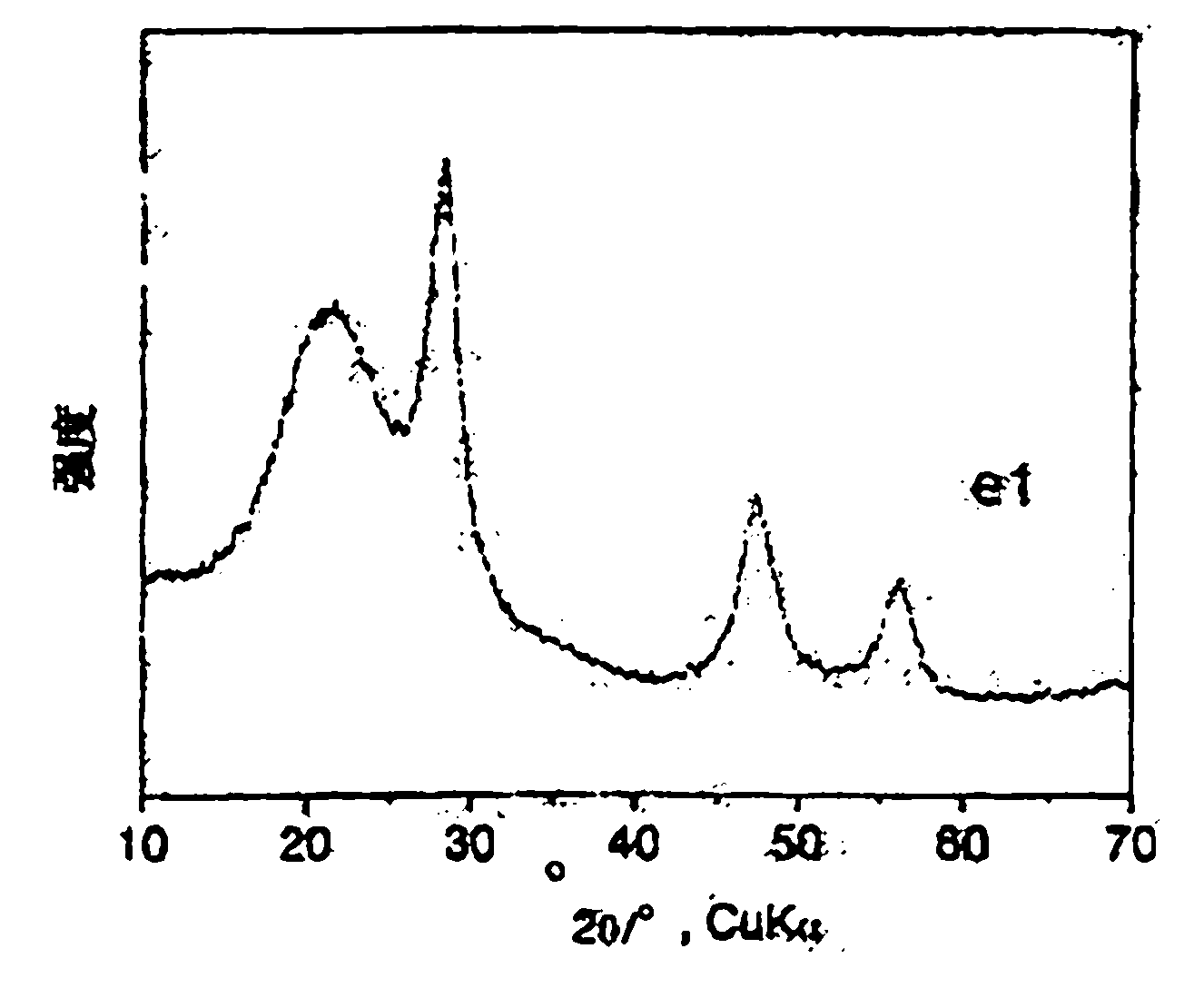

A non-aqueous electrolyte battery using a negative active material which is characterized by comprising Si and O at the atomic ratio of O to Si, x, being 0<x<2, and by showing a full width at half maximum of Si(220) plane peak, B, being B<3 degree (2 theta) at x-ray diffraction with CuKalpha radiation shows better cycle performance.

Description

technical field [0001] Technical Field of the Invention: The present invention relates to the negative electrode active material, its manufacturing method, the negative electrode with the active material, and the invention of the non-aqueous electrolyte battery. Background technique [0002] In recent years, non-aqueous electrolyte batteries having high energy density have been widely used as power sources for cordless phones, PDAs, digital cameras, and the like. With the development of cordless electronic devices, it is expected that non-aqueous electrolyte batteries will play an increasingly important role in the future. [0003] At present, graphite is mainly used as the negative electrode active material of non-aqueous electrolyte batteries, and lithium salts of lithium transition metal oxides are mainly used as the positive electrode active material. However, the energy density is not sufficient as a power source for next-generation electronic equipment. Therefore, in...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): H01M4/36H01M4/48H01M4/62H01M10/40H01M10/05C01B33/113H01M4/02H01M4/04H01M4/139H01M4/485H01M4/58H01M10/052H01M10/36

CPCY02E60/12H01M4/5825C01B33/113H01M4/485H01M2004/021H01M10/052H01M4/139H01M4/625Y02E60/122Y02E60/10H01M4/02H01M4/04H01M10/05

Inventor 船引厚志

Owner GS YUASA INT LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com