Novel technique for processing top grade rice

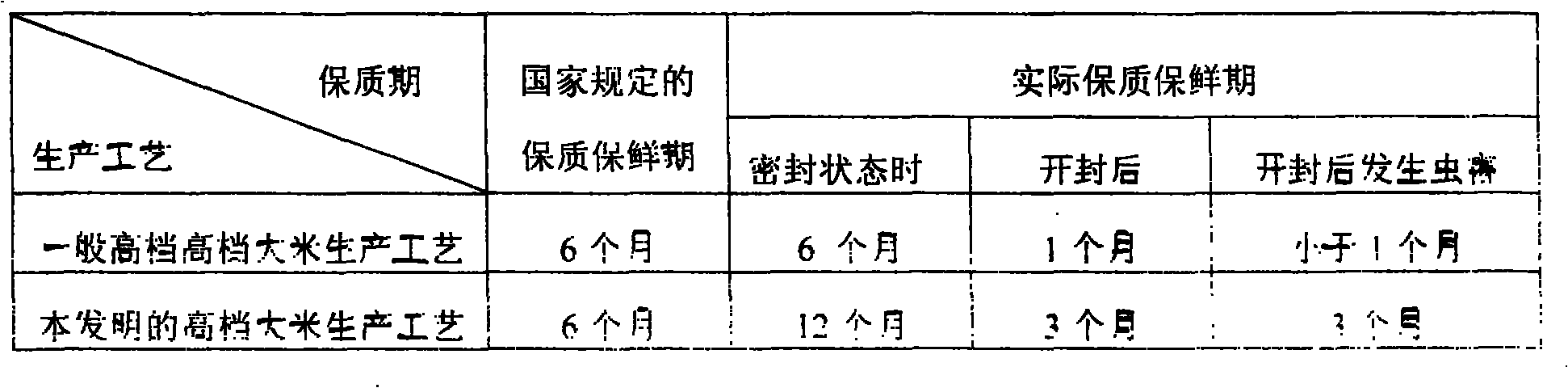

A technology of rice processing and new technology, applied in application, grain processing, agriculture, etc., can solve the problems of short shelf life of rice, harmful to human health, rice prone to insects, etc., and achieve extended shelf life, food hygiene and safety, The effect of increasing the number of varieties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The present invention will be further described below in conjunction with embodiment.

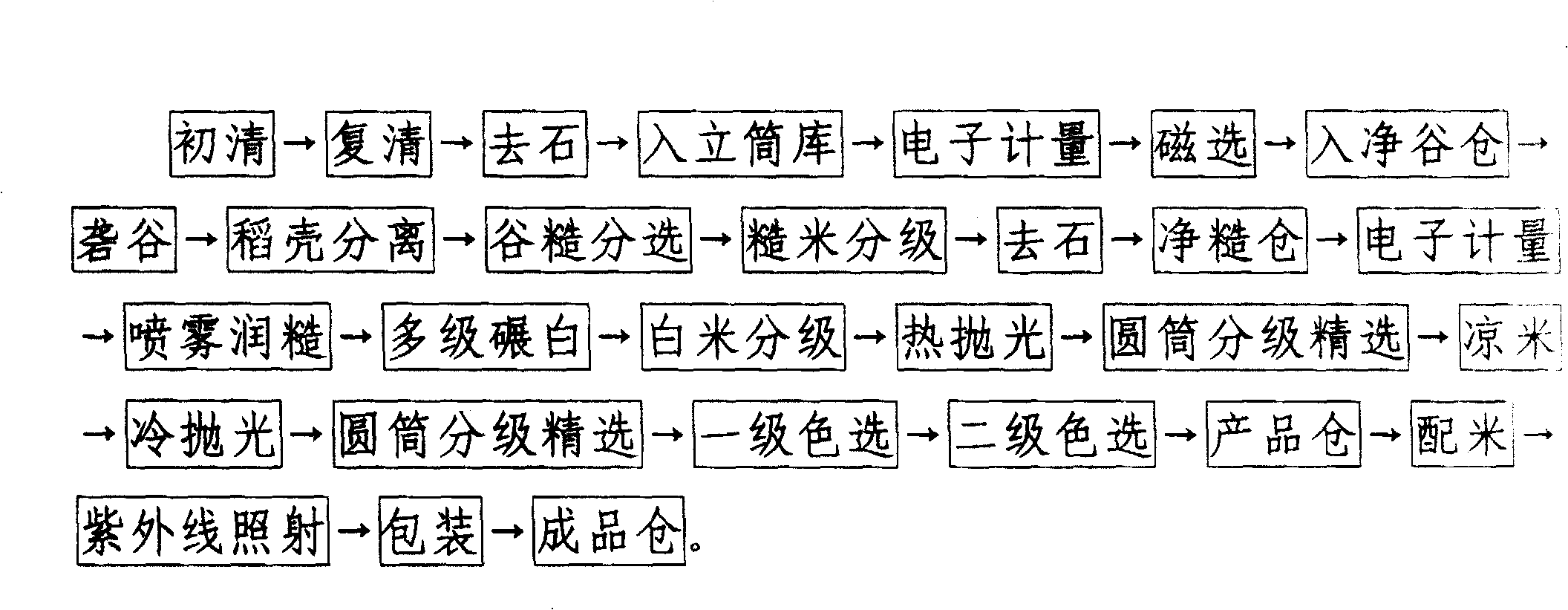

[0008] The technological process used in this example includes: initial cleaning → re-cleaning → stone removal → vertical silo → electronic measurement → magnetic separation → cleaning barn → rice hulling → rice husk separation → rice husk separation → brown rice classification → Stone removal→rough cleaning warehouse→electronic metering→spray moistening→multi-stage whitening→white rice grading→hot polishing→cylindrical grading and selection→cool rice→cold polishing→cylindrical grading and selection→first-level color sorting→secondary Color sorting→product warehouse→rice blending→ultraviolet irradiation→packaging→finished product warehouse. The equipment used mainly includes elevators, vibrating cleaning screens, suction separators, electronic weighing scales for bulk grains, vertical silos, air cushion belt conveyors, stone removers, magnetic separators, clean barns, huskers, grain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com