Wiring board and method of producing the same

A technology for wiring substrates and manufacturing methods, applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., can solve the problems of positioning accuracy obstacles, insufficient connection assistance, and easy occurrence, etc., to improve positioning stability, Good wettability and effective environmental countermeasures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034]Hereinafter, embodiments of the present invention will be described with reference to the drawings.

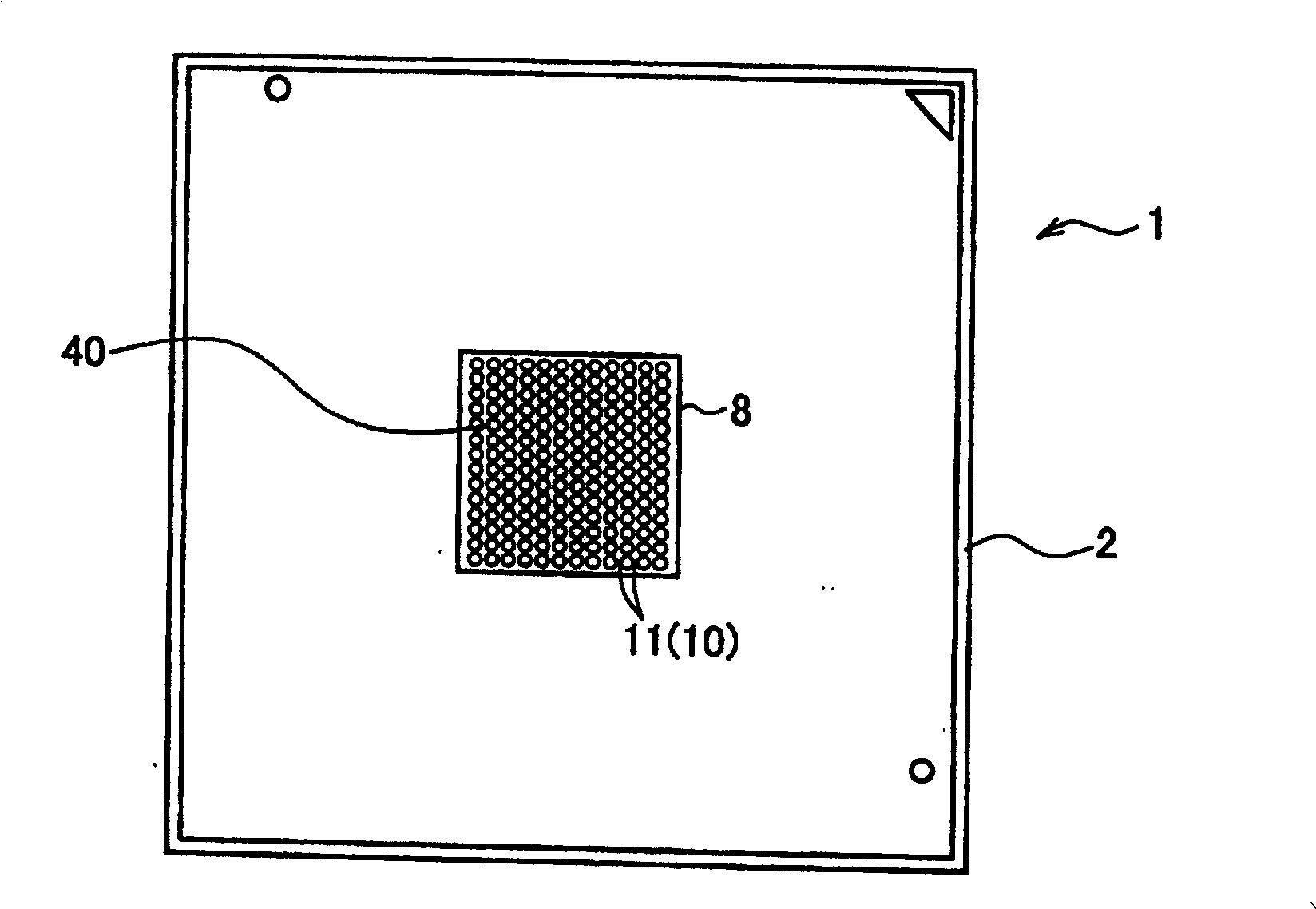

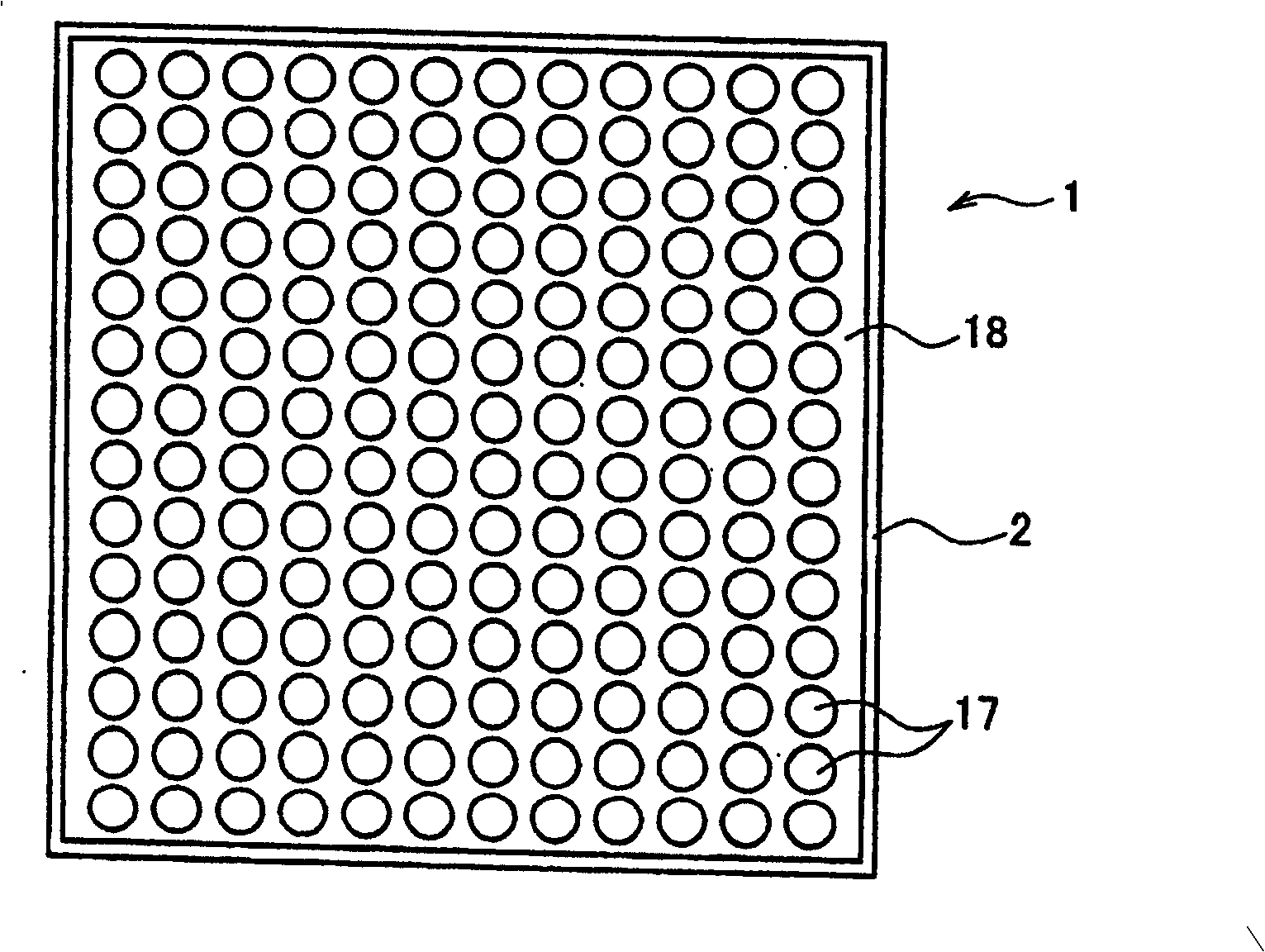

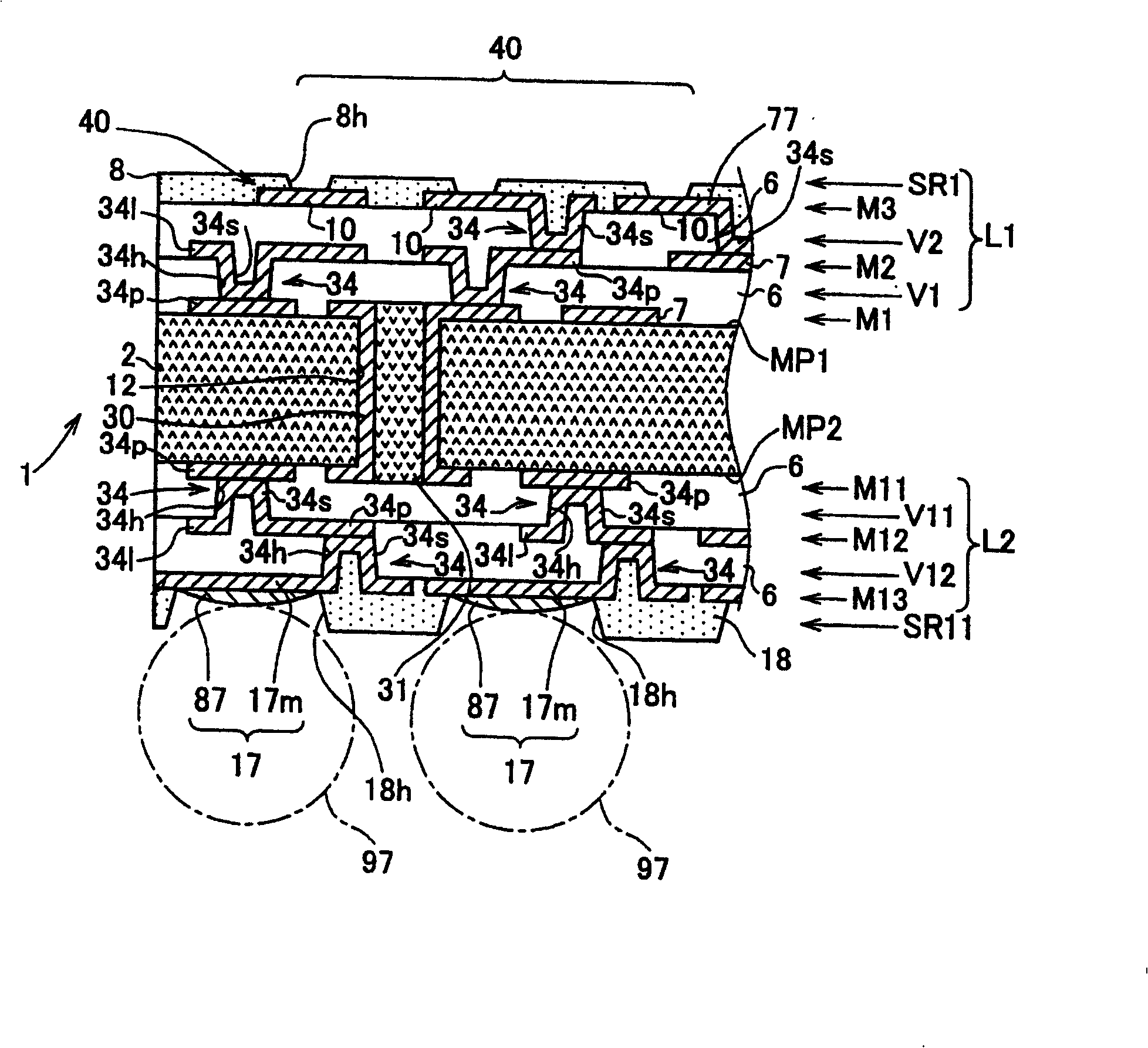

[0035] image 3 It is a figure which schematically shows the cross-sectional structure of the wiring board 1 which concerns on one Embodiment of this invention. The wiring substrate 1 is made of a plate-shaped core 2 made of a heat-resistant resin board (such as a bismaleimide triazine resin board) or a fiber-reinforced resin board (such as a glass fiber-reinforced epoxy resin). Core conductor layers M1 and M11 (referred to as conductor layers) constituting the wiring metal layer are respectively formed on both surfaces of the circuit board according to a predetermined pattern. These core conductor layers M1, M11 are formed as surface conductor patterns covering most of the surface of the plate-shaped core 2, and are used as a power supply layer or a ground layer. On the other hand, a through hole 12 drilled by a punch or the like is formed in the plate-shaped core 2, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com