Single component whilte inorganic electroluminous material and its preparation method

A technology of electroluminescent materials and luminescent materials, applied in the direction of luminescent materials, electroluminescent light sources, electric light sources, etc., can solve the problems of emission color change, color unevenness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

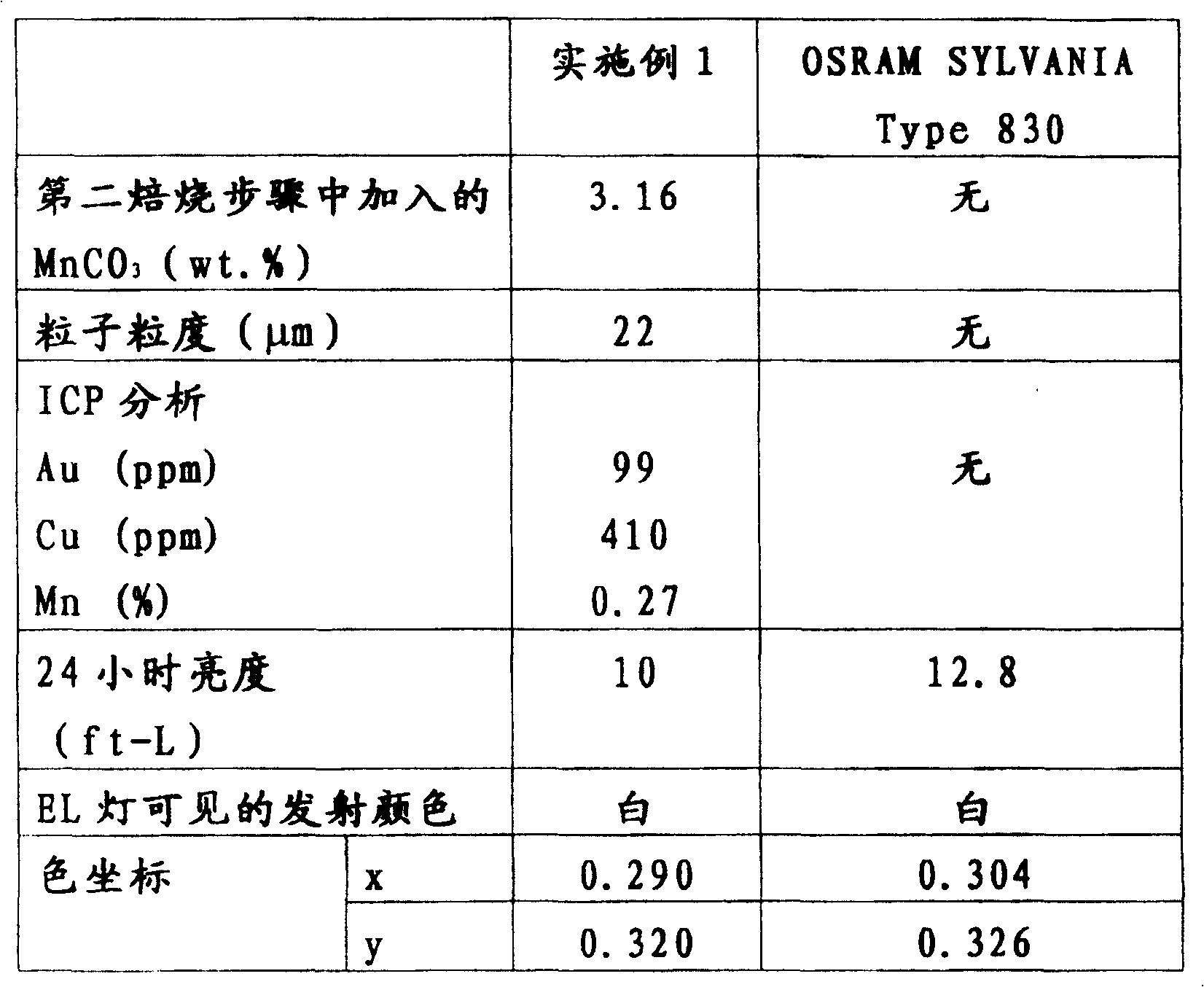

Embodiment 1

[0027] 550g ZnS containing about 1wt.% chlorine was mixed with 15.58g ZnS and AuCl containing 0.5wt.% Au 3 Mixture, 1.65g ZnS and Sb containing 1.67wt.% Sb 2 o 3 Mixture, 2.86g zinc oxide (ZnO), 45.66g sulfur, and a 8.56g barium chloride (BaCl 2 ), 25.68g magnesium chloride (MgCl 2) and a chloride flux of 11.42 g of sodium chloride (NaCl) were mixed. The ZnS mixture was then fired at 1150°C for 4 hours and 15 minutes in air. The fired material is cooled rapidly by placing the hot crucible in a water bath. The calcined material was then washed several times with hot deionized water to remove most of the chloride flux and dried at 120°C for 15 hours. The material was milled for 75 minutes and treated with acetic acid solution (2.8 M) followed by a solution containing 4 wt.% DTPA, 2.8 wt.% NaOH and 10 wt.% H 2 o 2 (30% solution) alkaline solution for washing. The phosphor was then washed with hot deionized water and dried at 120° C. for 15 hours to complete the first firi...

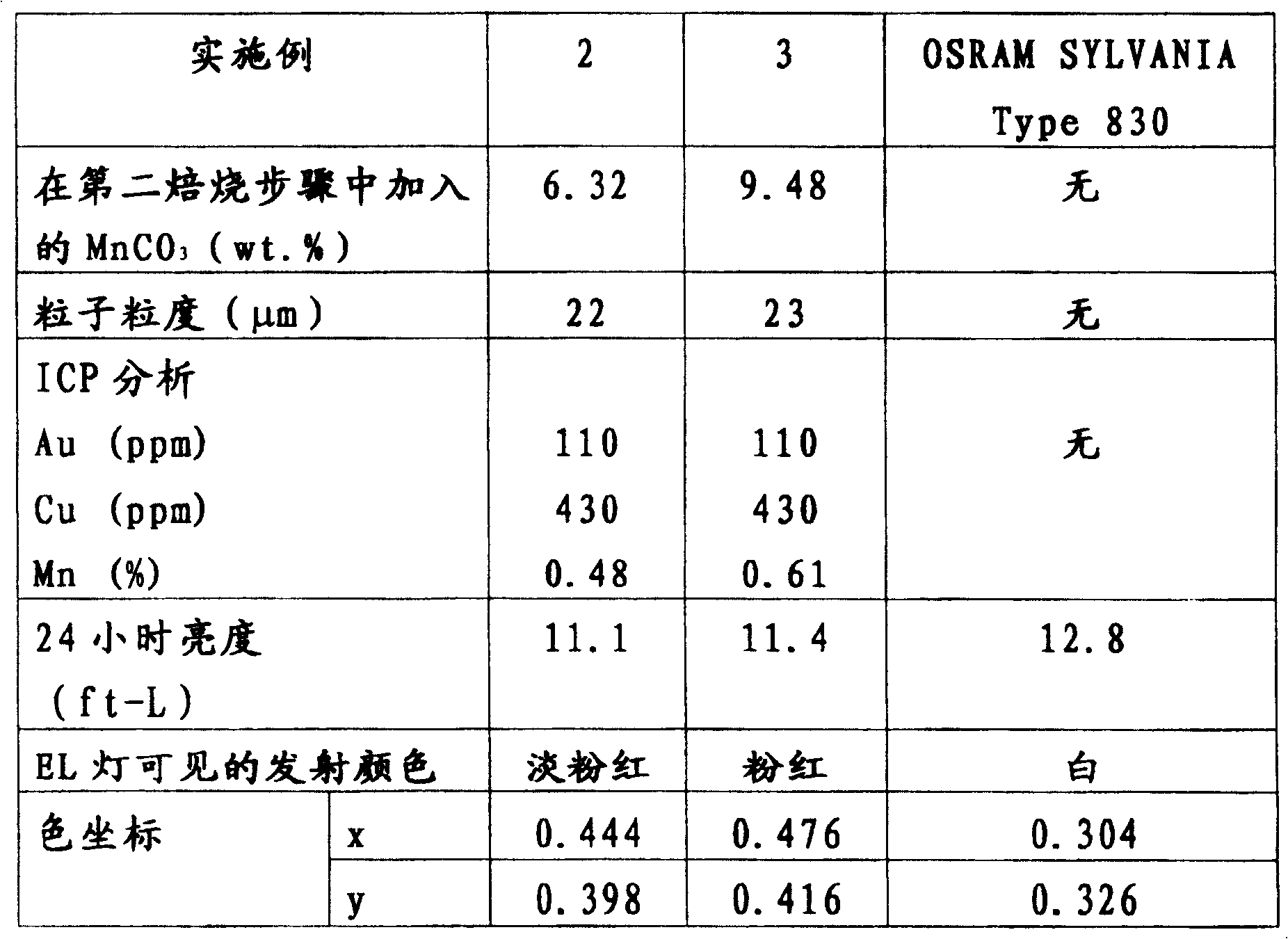

Embodiment 2-3

[0032] The fabrication of these two examples is the same as in Example 1, except that, as indicated in Table 2, in the second firing step the MnCO 3 The total amount added is different. The data show that increasing the total amount of Mn changes the color of the lamp, making it appear pink.

[0033] Table 2

[0034]

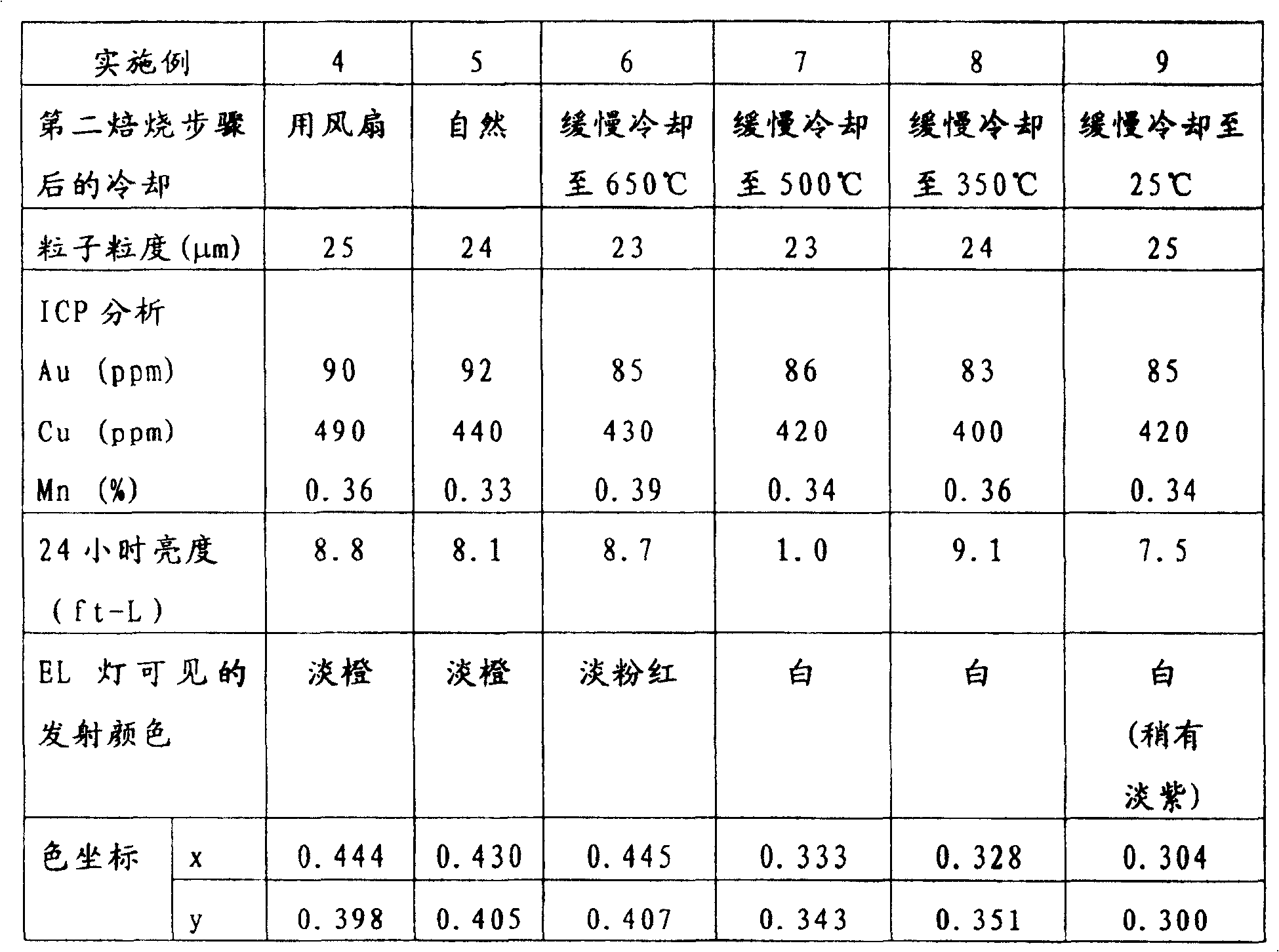

Embodiment 4-9

[0036] These examples were made the same as Example 1 except that they were cooled differently after the second firing step as indicated in the table. The data in the table shows that adding 3.16w t.% MnCO in the second roasting step 3 and slowly cooled to a temperature between 500 and 350°C suitable for obtaining a white color. In this table, "with a fan" means that after the second firing step, the material was rapidly cooled to below about 200°C by means of a fan within 20 minutes. "Natural" means that the example was allowed to cool naturally outside the furnace, and cooling to below 200°C took about 40 minutes. The slow cooling rate for Examples 6-9 was about 2 degrees per minute.

[0037] table 3

[0038]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com