Directional magnetic electrical spinning Nano fibers, preparation method and equipment needed

An electrospinning nanofiber, magnetic technology, applied in fiber processing, textile and papermaking, fiber chemical characteristics and other directions, can solve the problem of magnetic nanofiber preparation method that has not been reported yet, achieves easy popularization and application, simple preparation process, Easy to manipulate and repeatable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

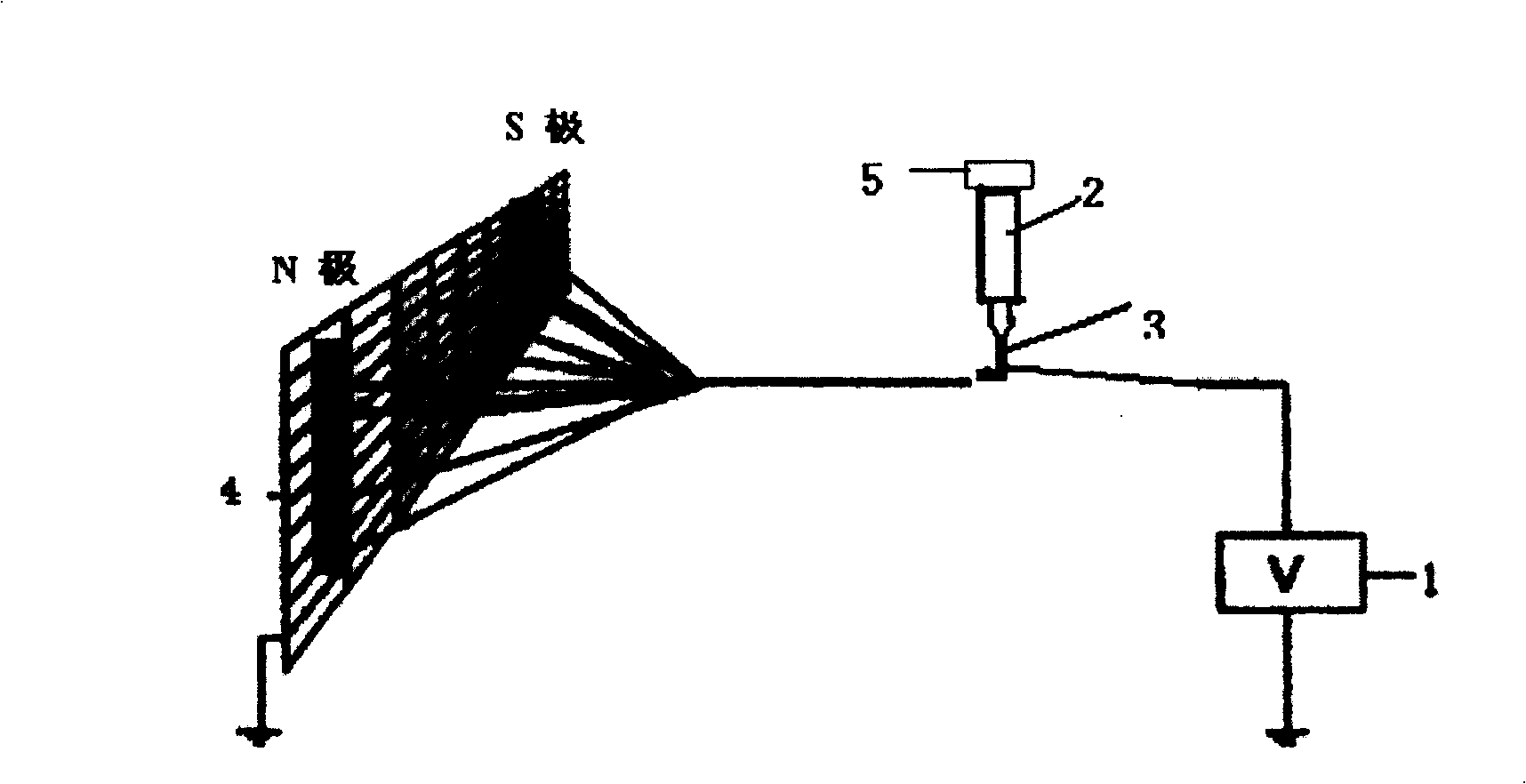

Method used

Image

Examples

Embodiment 1

[0024] A. In a 100mL volumetric flask, prepare FeCl with a concentration of 0.1mol L with distilled water 2 with FeCl 3 solution; add 35mL 0.1mol·L FeCl in a round bottom flask with mechanical stirring 3 solution and 20mL 0.1mol·L FeCl 2 The solution is mixed evenly, and nitrogen gas is passed under the liquid surface to remove oxygen in the water. The temperature of the reaction device was raised to 80°C, and the ammonia water was slowly added dropwise to the solution until the pH value of the solution was 6.5. After 15 minutes of reaction, the ammonia water was slowly added dropwise to the solution until the pH value was 9.5, and the reaction was stopped after 30 minutes of reaction; Hold the bottom of the flask with a strong magnet, pour off the upper liquid, and wash the reaction product repeatedly with distilled water until the washing liquid is neutral; the product Fe 3 o 4 Freeze drying;

[0025] B. The dried Fe 3 o 4 The nanoparticles are dispersed in the aqueou...

Embodiment 2

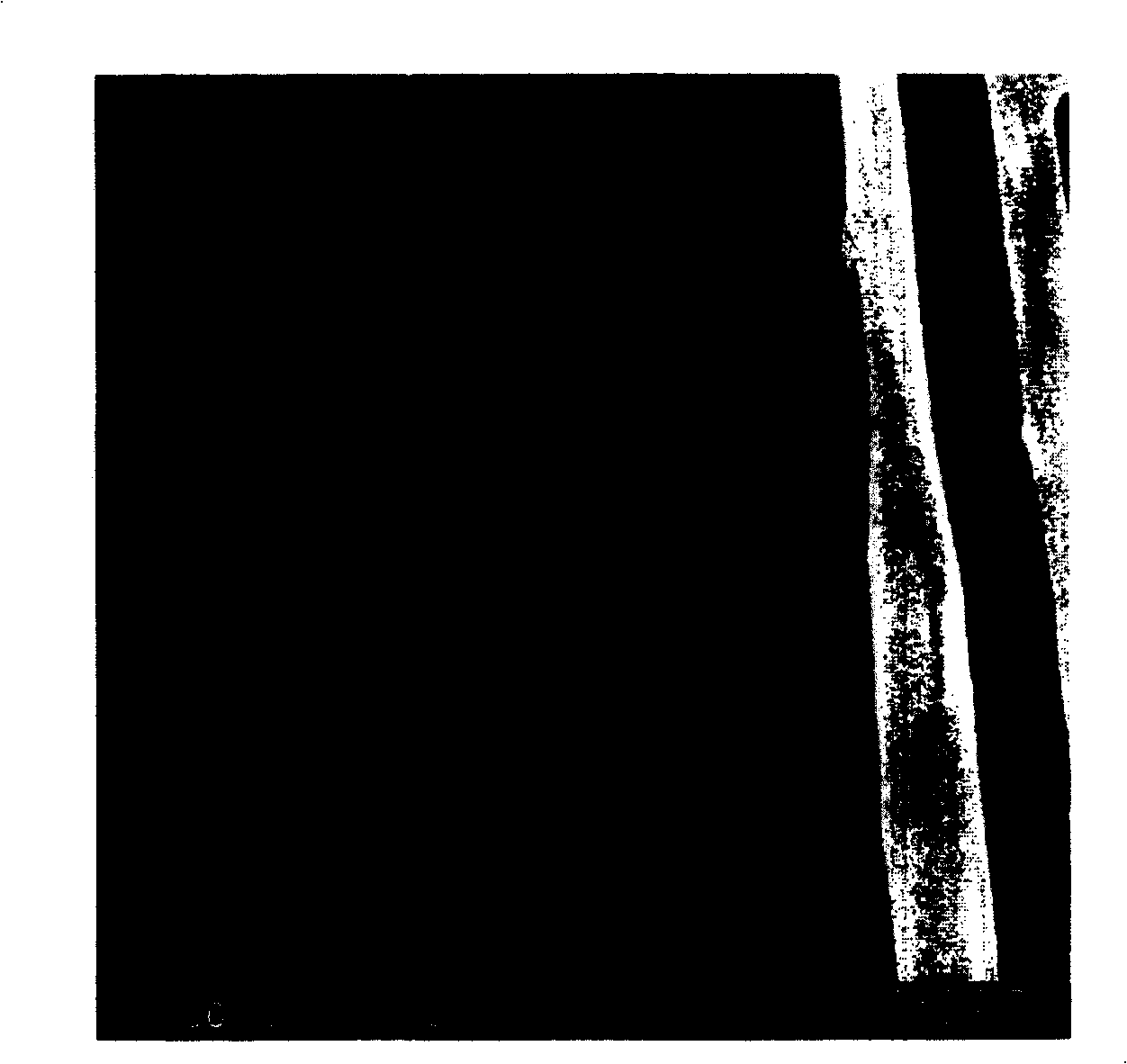

[0029] Fe 3 o 4 The mass ratio of polyvinyl alcohol to polyvinyl alcohol is 1:100, and the rest of the experimental conditions and the amount of reaction substances are the same as in Example 1 to obtain nanofibers with a fiber diameter distribution of 100-600 nm and aligned along the direction of the magnetic field.

Embodiment 3

[0031] Fe 3 o 4 The mass ratio of polyvinyl alcohol to polyvinyl alcohol is 50:100, and the rest of the experimental conditions and the amount of reaction substances are the same as in Example 1 to obtain nanofibers with a fiber diameter distribution of 100-600 nm and aligned along the direction of the magnetic field.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| adsorption strength | aaaaa | aaaaa |

| adsorption strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com