Gypsum board having polyvinyl alcohol binder in interface layer and method for making the same

A polyvinyl alcohol and gypsum board technology, applied in the field of gypsum board, can solve the problems of reducing the bonding strength of the cured gypsum core and the paper surface material, and achieve the effect of light weight and good adhesion properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] The following example illustrates the preparation of gypsum board according to the present invention having a paper facestock (70 lbs. / in.) tensile strength) and a pre-coated fiberglass mat facestock. The formulation described below was used as a thin coating applied to the paper facestock layer.

[0064] composition

lbs. / 1000 square feet

Burnt gypsum (CaSO 4 1 / 2H 2 O)

about 140

Celvol TM 203-24 (24% aqueous polyethylene

alcohol, 100% hydrolyzed)

2.2

≥4.3

≤2.0

Potassium sulfate (accelerator)

≤1.5

Landplaster (Accelerator)

when needed

fluid blockers

when needed

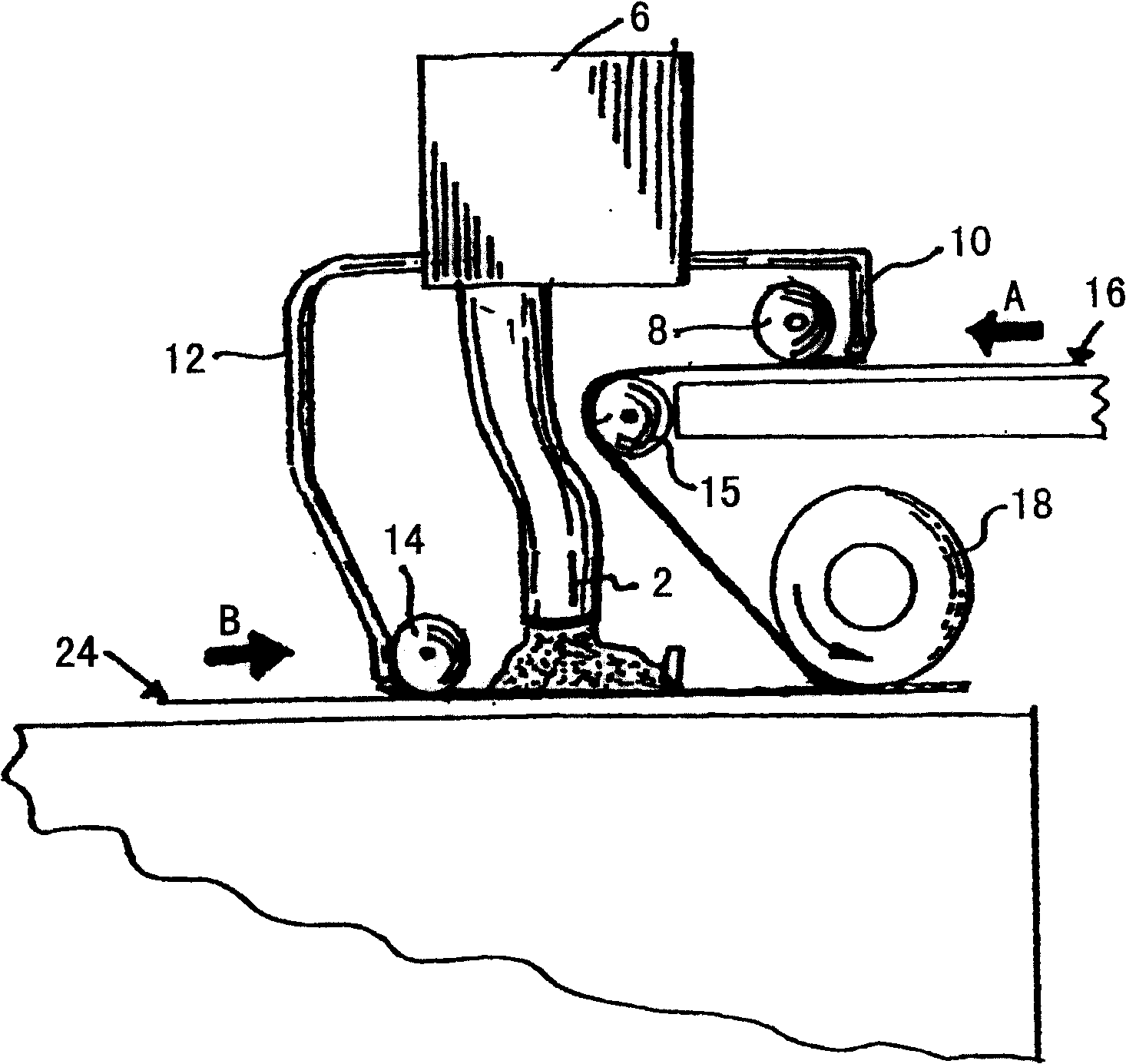

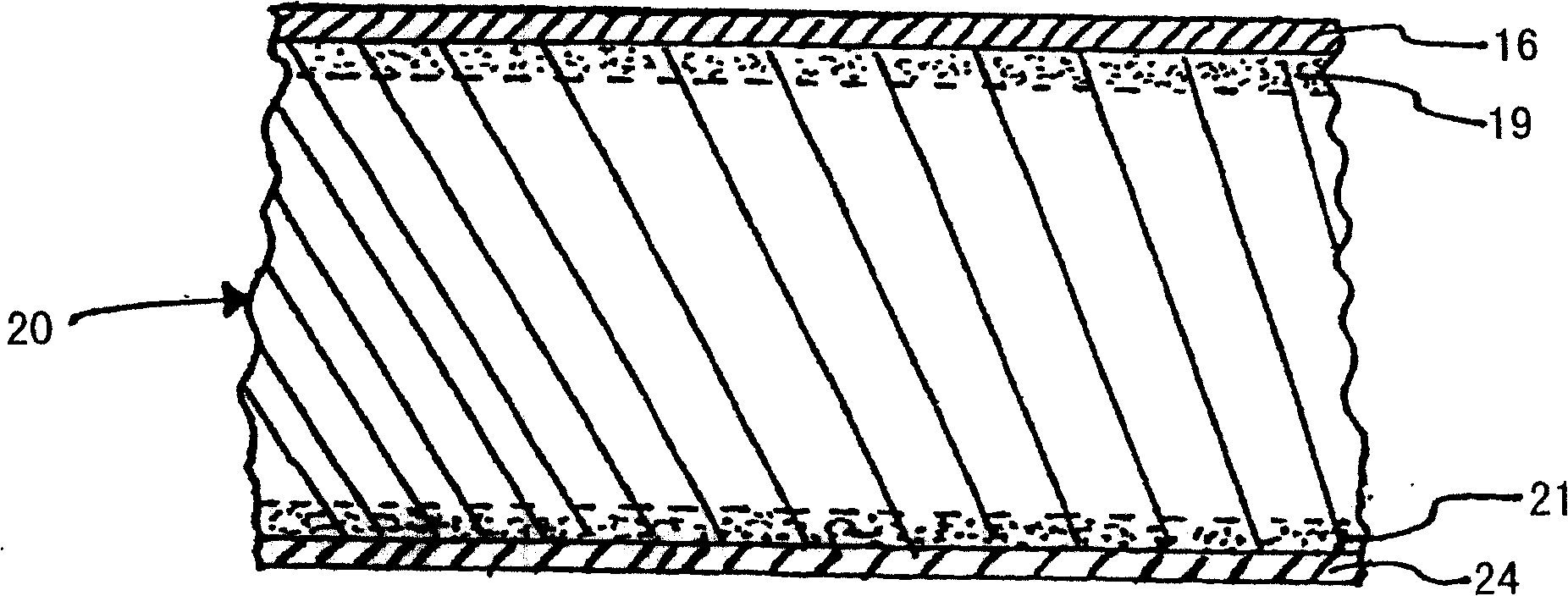

[0065] The above formula is applied to paper face stock. Additional aqueous gypsum slurry was then applied to the coated paper facestock to form the core so that the total amount of calcined gypsum applied was about 1380 lbs. / MSF. Continuous length panels were produce...

Embodiment 2

[0068] This example illustrates the preparation of a gypsum board (70 lbs. / in. tensile strength) having a set gypsum core adhered to a paper facestock. In Examples 2A and 2B, polyvinyl alcohol was used in the slurry used to make the gypsum core. Example 2C is a control where no polyvinyl alcohol was used and starch and soap were used in the slurry.

[0069]

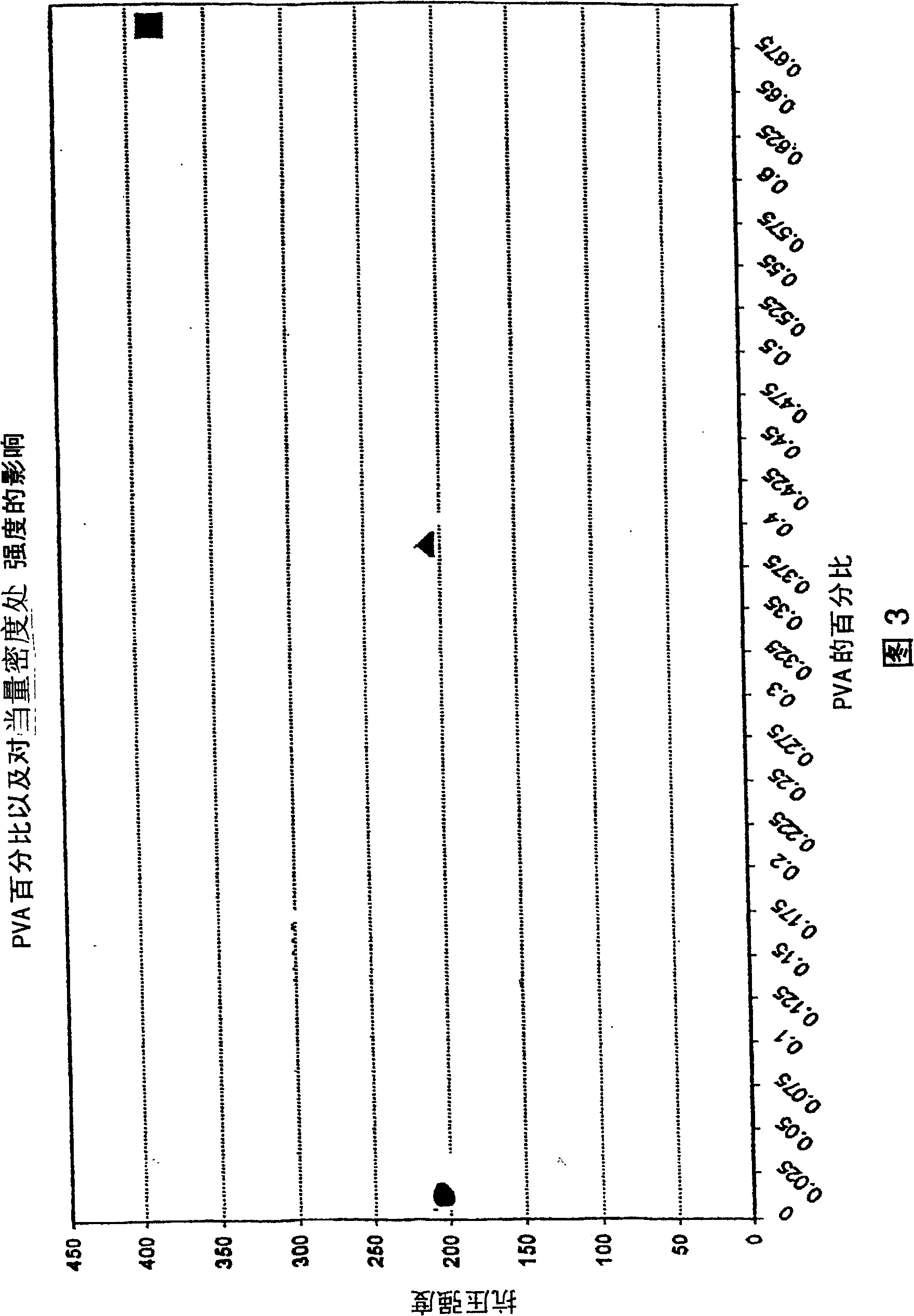

[0070] Figure 3 graphically illustrates the effect of polyvinyl alcohol on the compressive strength of gypsum board. The panel of Example 2A (represented by the blackened squares in Figure 3) exhibited the highest compressive strength and had 33.5 lbs. / ft at a water to gypsum (w / p) weight ratio of 90 / 1 3 density of. The panel of Example 2B using soap in the core (represented by the blacked out triangles in Figure 3) had 31.5 lbs. / ft at a w / p weight ratio of 90 / 1 3 density of. The board of Example 2C using starch and soap in the core (represented by the blackened circles in Figure 3) had 32 lbs. / ft at a w / p w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com