Desliming jigger and coal preparation

A jig and desliming technology, applied in chemical instruments and methods, wet separation, solid separation, etc., can solve the problem of increasing the difficulty of separating low-ash coarse minerals and high-ash fine minerals, and low clean coal cleaning degree. , Reduce the quality of concentrates and other problems, to expand the scope of equipment use, improve the separation effect, and stabilize product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

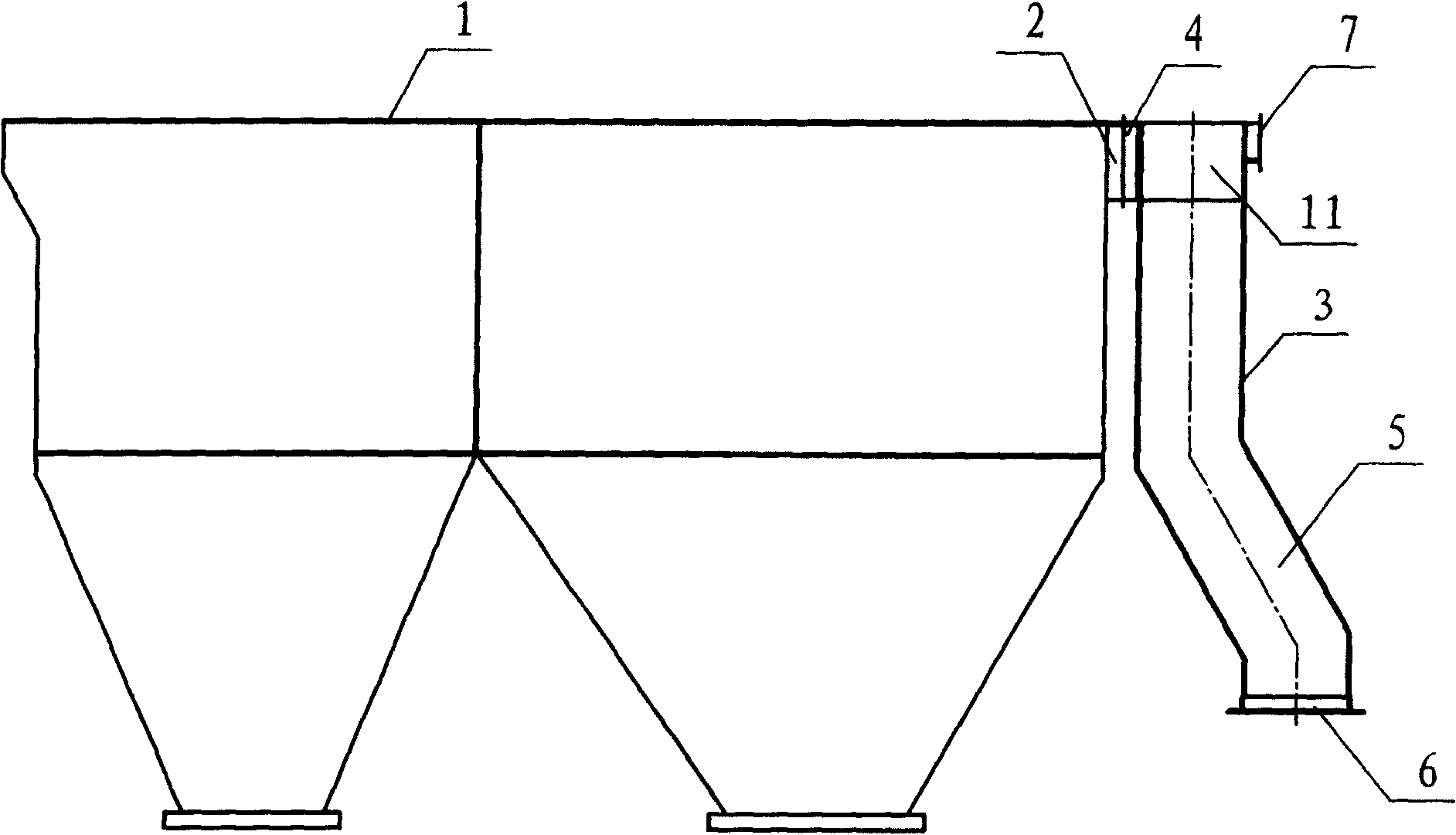

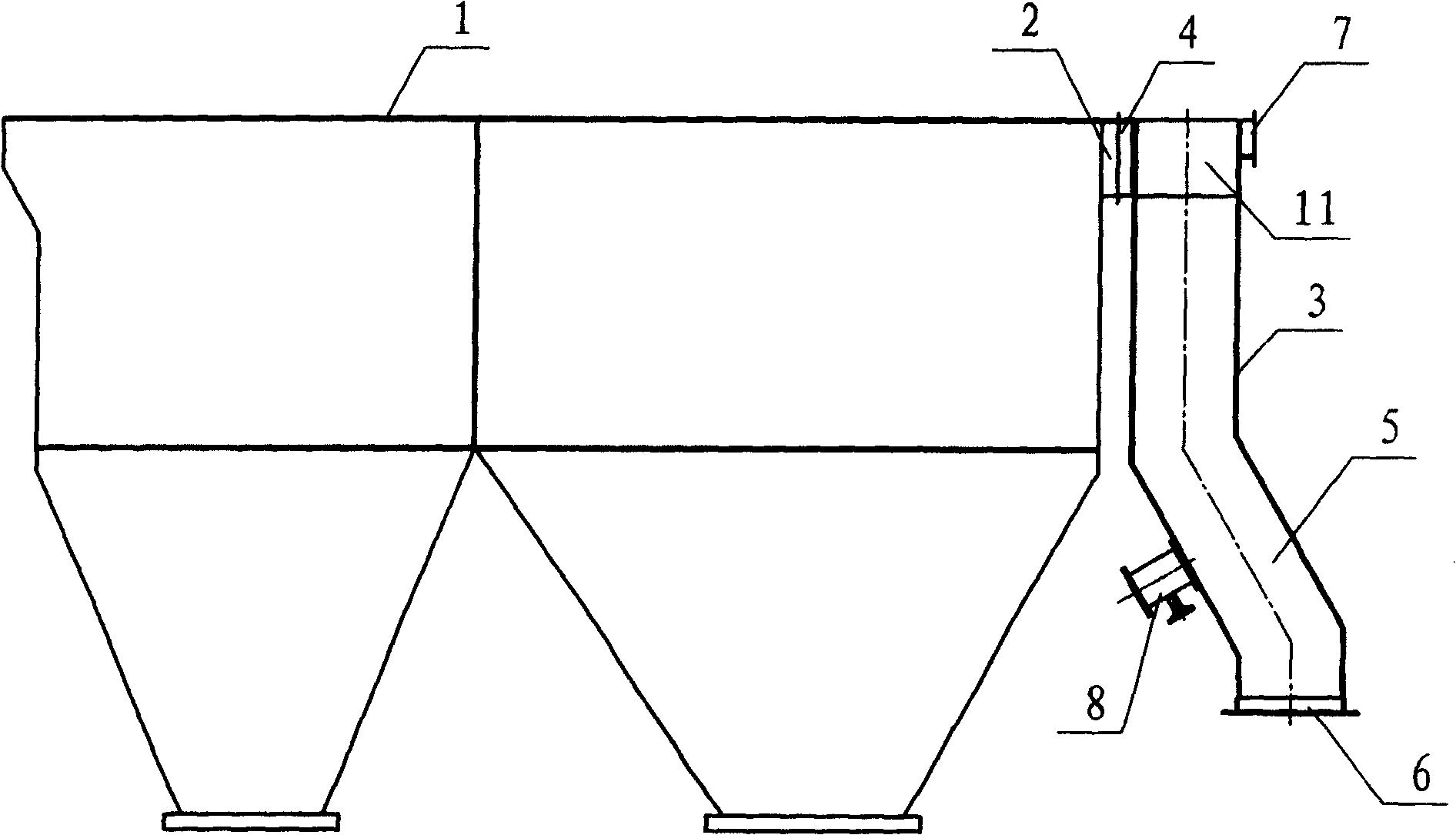

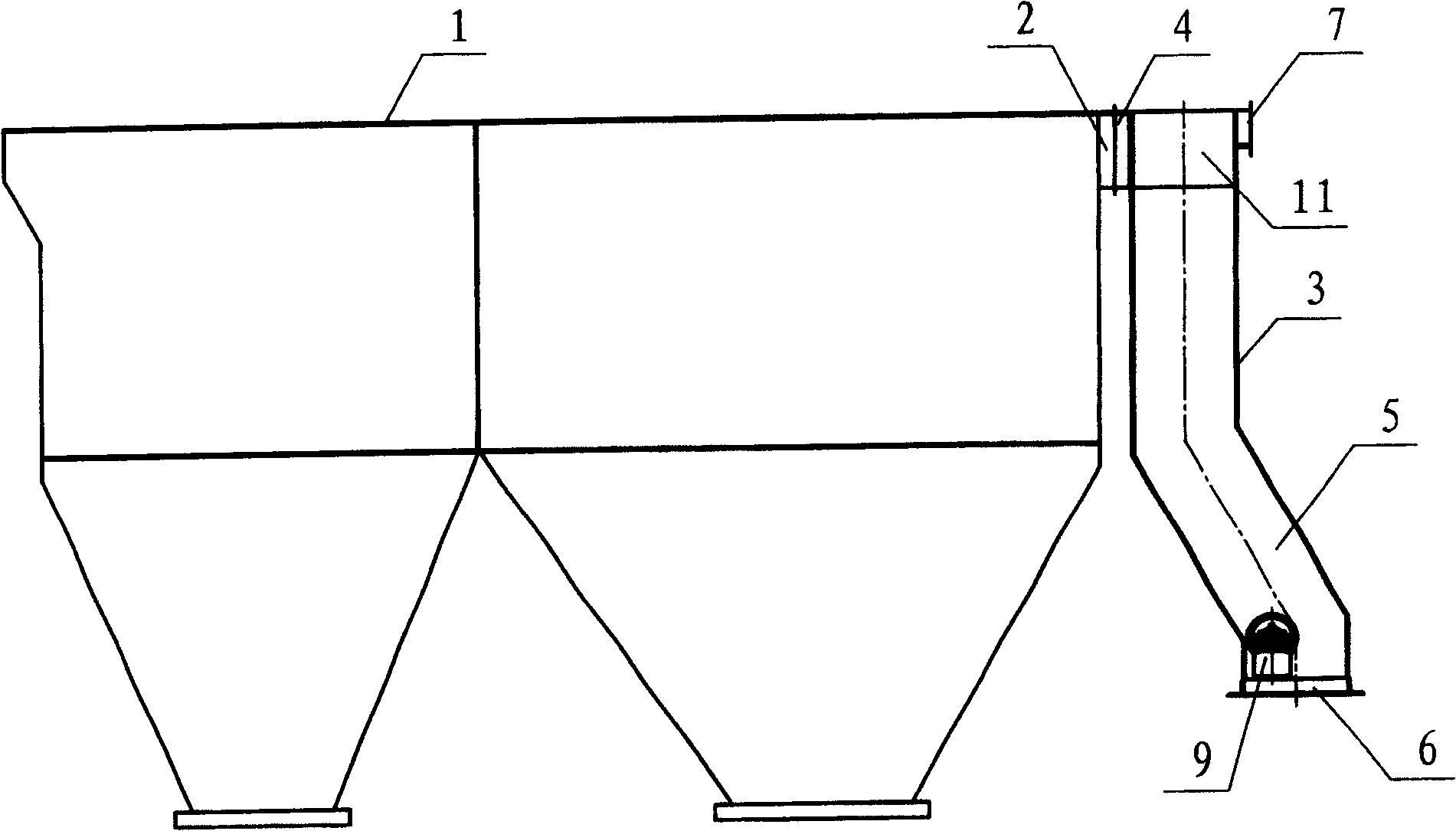

[0030] Below in conjunction with accompanying drawing, the present invention will be further described:

[0031] exist figure 1 Among them, a desliming jig is a two-stage desliming jig, which includes a common jig body 1 and a coal-water separation device 3 . The feed port 4 of the coal-water separation device 3 is adapted to the clean coal outlet 2 of the common jig machine body 1, and is sealingly connected with the periphery of the clean coal outlet 2. The coal-water separation device 3 is a closed device with an upper opening, and the uppermost part of the device is a cuboid-shaped separator 11. The upper part of the front end of the separator 11 is provided with a feed port 4, and the upper part of the rear end is provided with an overflow port 7. , The bottom is provided with a discharge channel 5, and the bottom end of the discharge channel 5 is provided with a discharge port 6. The discharge channel 5 can be straight, can also be made into various bends, can also be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com