Sprinkling equipment for chemical treatment of fabric

A technology of spraying equipment and fabric chemistry, which is applied in the direction of spraying/jetting textile materials, textiles and papermaking, papermaking machines, etc. It can solve the problems of not being able to achieve the best treatment effect, low utilization rate of chemical reagents, narrow application range, etc. , to achieve the effect of not easy to pollute, water permeability, light weight and good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

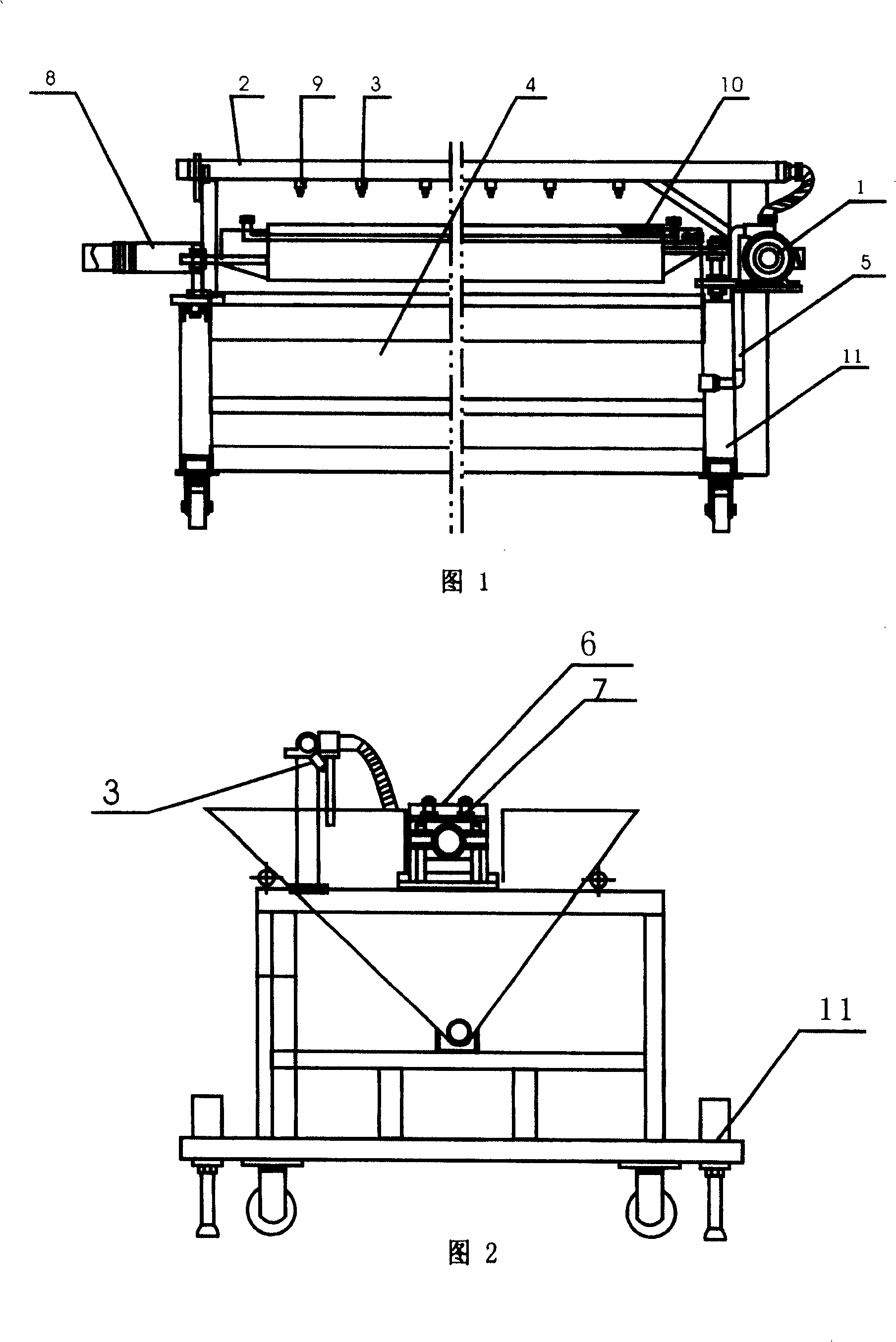

[0011] According to the accompanying drawings, in the figure: 1, vortex pump; 2, spray pipe; 3, nozzle; 4, liquid storage tank; 5, suction pipe; 6, vacuum suction box; 7, seam adjustment bar; Box suction pipe; 9. Ball valve; 10. Paper blanket; 11. Mobile frame.

[0012] The present invention is realized as follows: a spraying equipment for chemical treatment of fiber fabrics, comprising a vortex pump 1, a nozzle 2, a nozzle 3, a vacuum suction box 6 and a suction box suction pipe 8, and the suction box suction pipe 8 is arranged on the workpiece to be sprayed Below the bottom, the suction box suction pipe 8 is connected to the vacuum suction box 6 with a pipe, and the spray equipment is installed on the upper side in the liquid storage tank 4. The bottom of the liquid storage tank 4 container is provided with a suction pipe 5, and the liquid suction The pipe 5 is connected to the vortex pump 1 .

[0013] The operation procedure on the equipment is as follows: dissolve the che...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com