Method for fabricating refined ballstone

A production method and ball stone technology, applied in the field of refined ball stone production, can solve problems such as difficulty in producing high-quality ball stones, and achieve the effect of improving the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

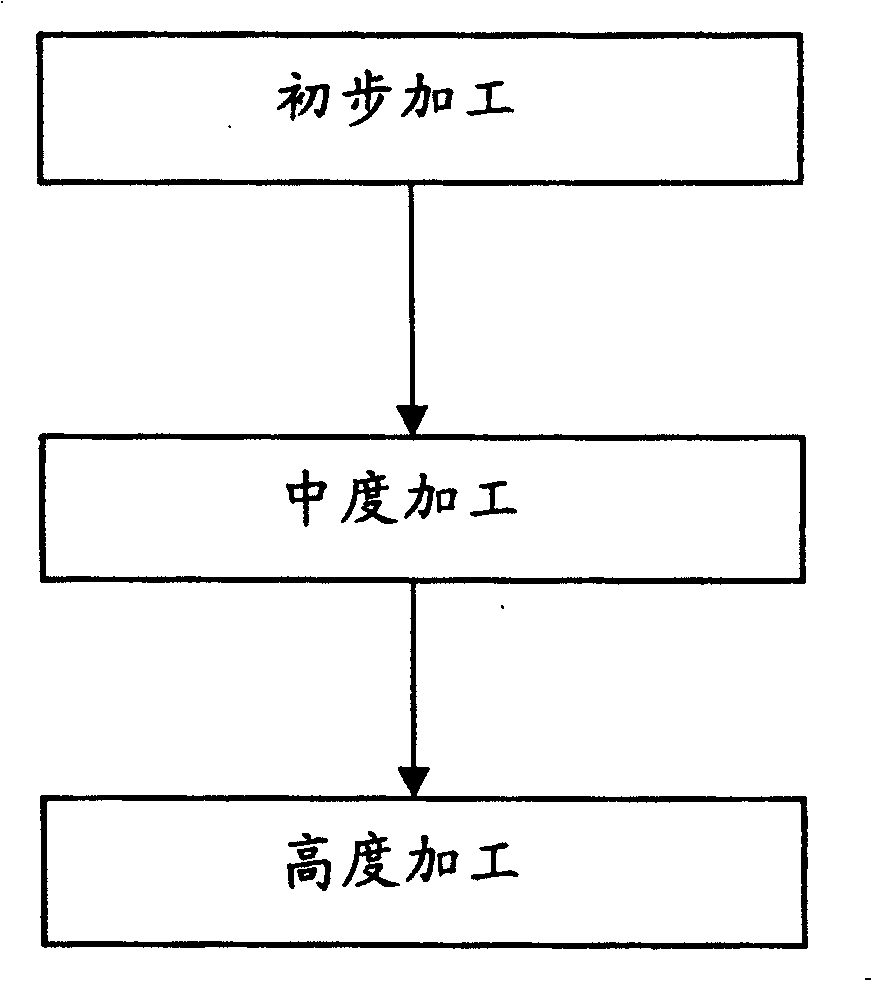

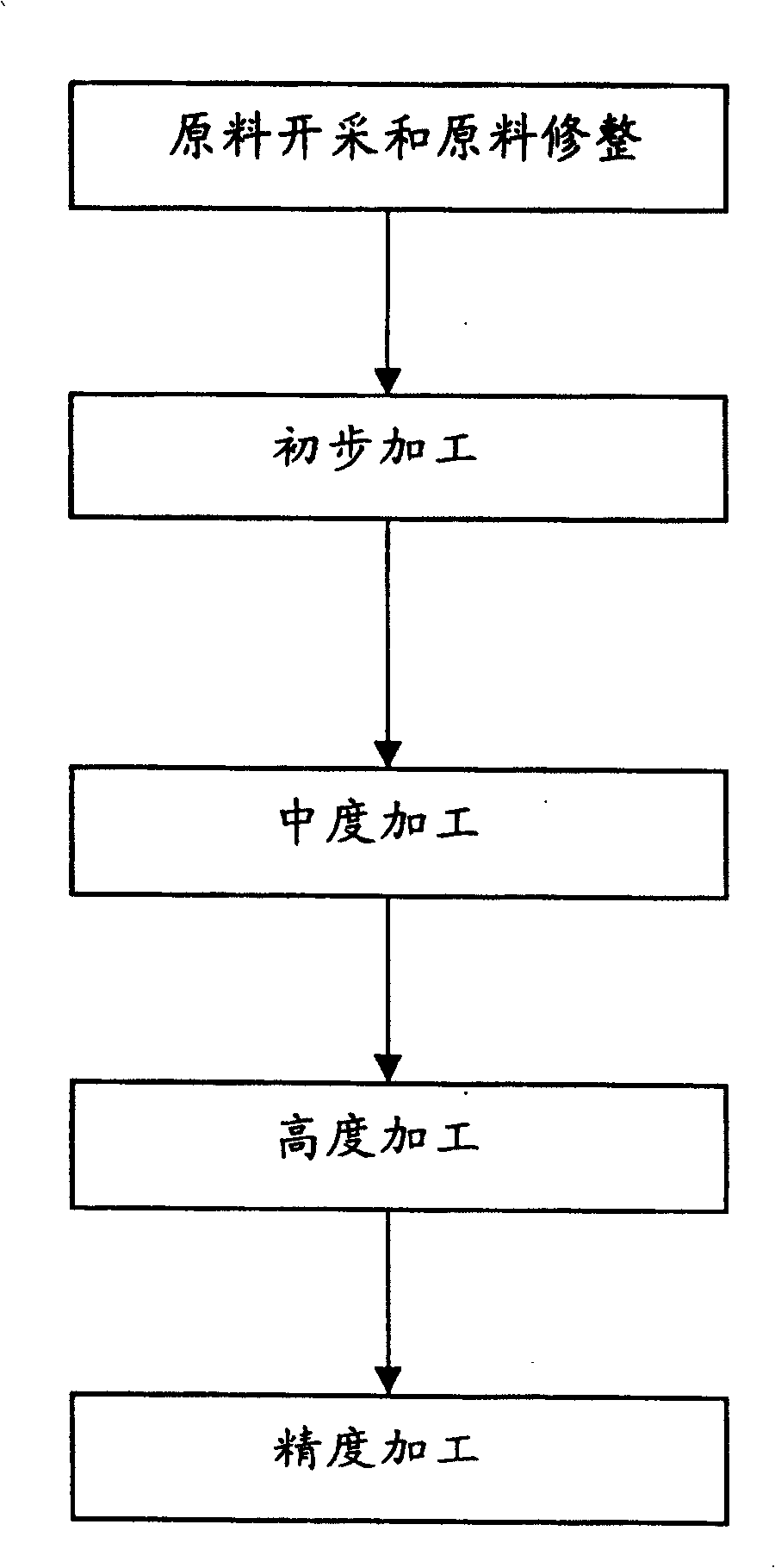

[0027] A method for producing refined ball stones, such as figure 1 As shown, the method includes the following steps:

[0028] (1) Preliminary processing: Put the raw materials into the grinding barrel of the ball stone mill, and keep a reserved distance between the upper surface of the raw material and the top of the grinding barrel after loading; the grinding barrel rotates to make the raw materials rub against each other; during the processing, at least One raw material addition process;

[0029] (2) Moderate processing: on the basis of preliminary processing, add at least one semi-finished product after preliminary processing in the past, and continue to rotate and rub;

[0030] (3) High degree of processing: on the basis of moderate processing, add at least one semi-finished product after moderate processing in the past, and continue to rotate and rub;

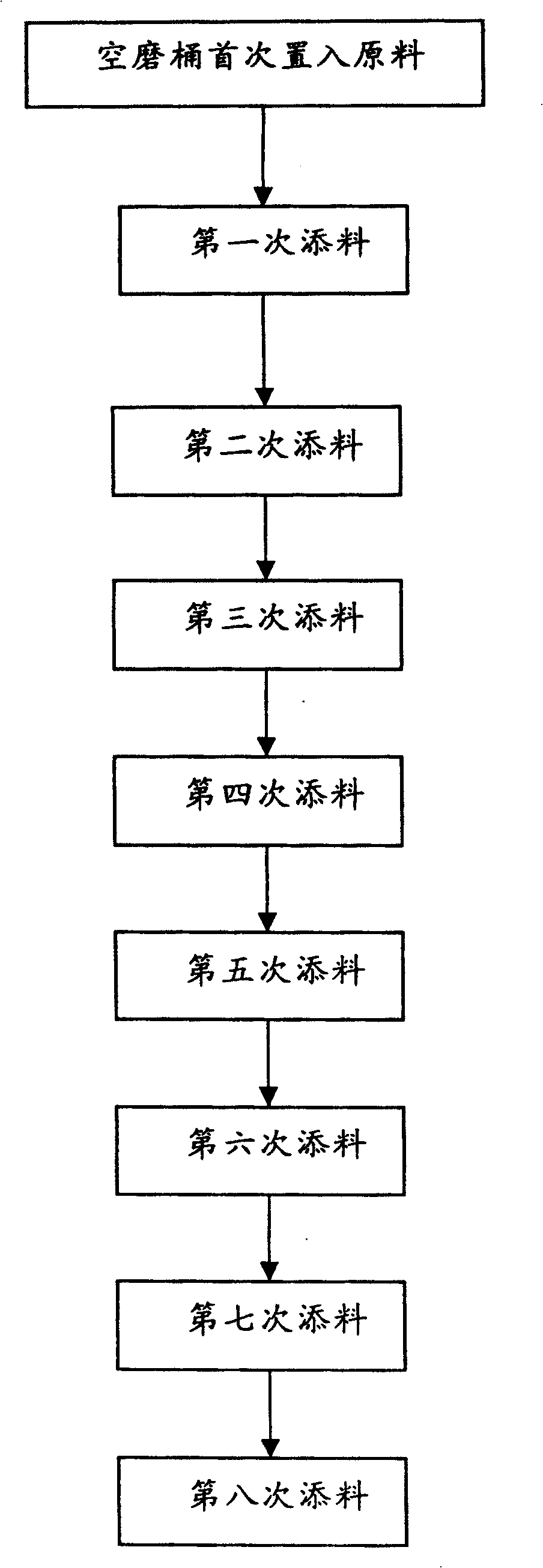

[0031] As shown in Figures 6 and 7, in the above-mentioned preliminary processing, intermediate processing and advan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com