Method for preparing water-soluble essence in orange smell in high concentration

A production method and water-soluble technology are applied in the production field of high-concentration water-soluble citrus flavors, which can solve the problems of short fragrance retention time, poor water solubility and low separation efficiency, and achieve long-lasting fragrance retention time and pure taste. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

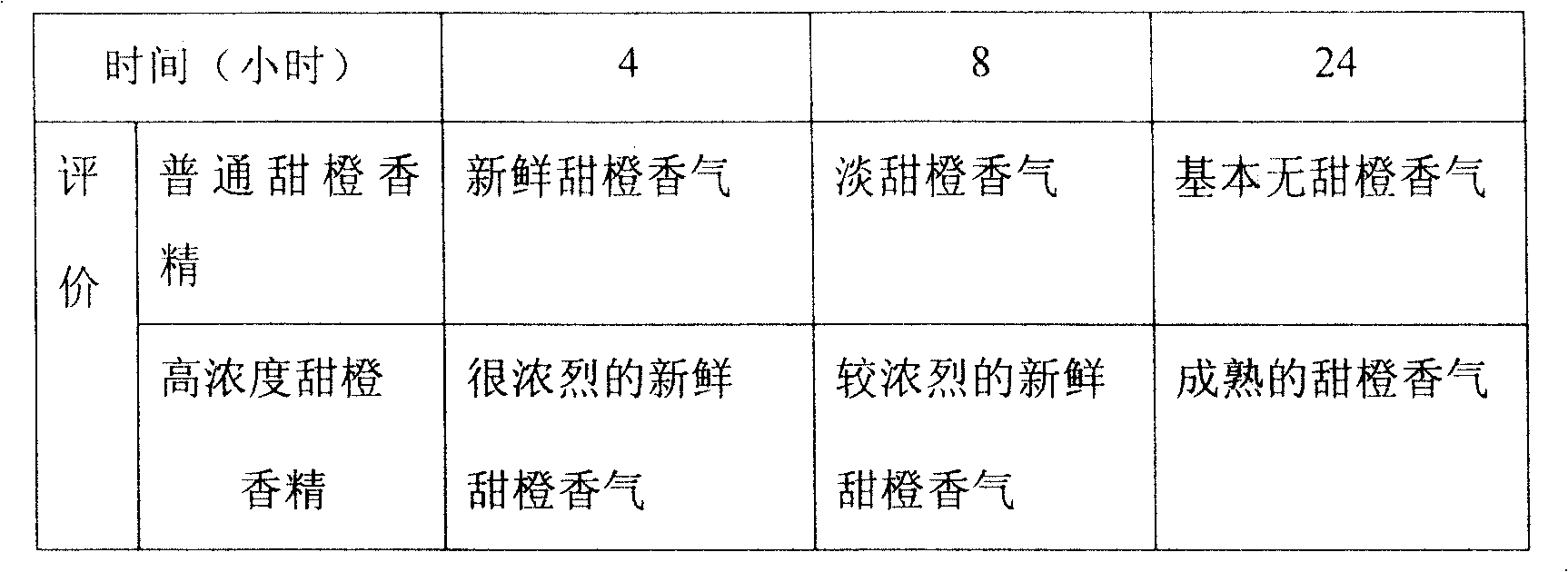

Examples

Embodiment 1

[0017] A set of small fractionation columns, the falling film evaporator has an evaporation area of 0.04M2, a diameter of 24mm, and a packing height of 800mm. Add 200g of natural sweet orange oil, then vacuumize to maintain a vacuum of 42000pa. Slowly heat the sweet orange oil, slowly rising from room temperature, 2°C / 10 minutes. Steam gradually appears at the upper end of the fractionation column, which is condensed by the condenser at -30°C and collected into the bottle. This is called top fragrance. About 0.5-0.8g (A), the main component is C4-C6 aliphatic aldehydes and related esters, with a pronounced fresh fruit aroma. Then gradually increase the temperature of the distillation flask to 50-80°C, and gradually increase the vacuum to 1000pa. 175 g of a second fraction (B) were obtained which were 99% limonene and had a light fruity aroma. The remaining material is the third fraction (C) 22g, mainly various oxygen-containing compounds, and the total aldehyde content is...

Embodiment 2

[0020] The evaporation area of 5000g natural sweet orange oil in the falling film evaporator is 0.1M 2 , Diameter 45mm, on the fractionating column of filler height 1500mm, fractionate by example one mode, obtain respectively component (A) 12.5g, component (B) 3050g, component (C) 1012g. The remaining components were subjected to a vacuum of 10 Pa at 80-100° C. on a short-range fractionation device to obtain 600 g of component (D). Component (D) contains 3-4% of neral and has a sweet orange aroma. Continue to distill at 110-125° C. to obtain 150 g of component (E), which contains 0.6% citron. Get 1 part of (A), 2 parts of (B), 50 parts of (C), 20 parts of (D), 6 parts of (E) and add 75 parts of 95% food grade ethanol and 22 parts of distilled water to obtain the sweet orange after blending The essence has a sweet and strong aroma of ripe sweet orange, which still has the aroma of sweet orange after 72 hours.

Embodiment 3

[0022] Tangerine oil 200g, carry out fractionation in the fractionating column of example one, obtain component (A) 0.6g, component (B) 140g, main component is limonene and terpinene, component (C) 54g, main component are oxygen compounds. Component (C) was freeze-dewaxed to obtain 52 g. Get 2 parts of (A), 1 part of (B), 32 parts of (C) and add 55 parts of 95% edible grade ethanol and 20 parts of distilled water, and the tangerine oil obtained after reconciliation has a strong tangerine aroma.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com