Production method of sesquiterpene-free orange oil

A production method, sesquiterpene technology, applied in the production field of sesquiterpene-free citrus oil, can solve the problems of large loss, difficult sealing, easy leakage, etc., to improve contact, improve performance, and increase fluid turbulence Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

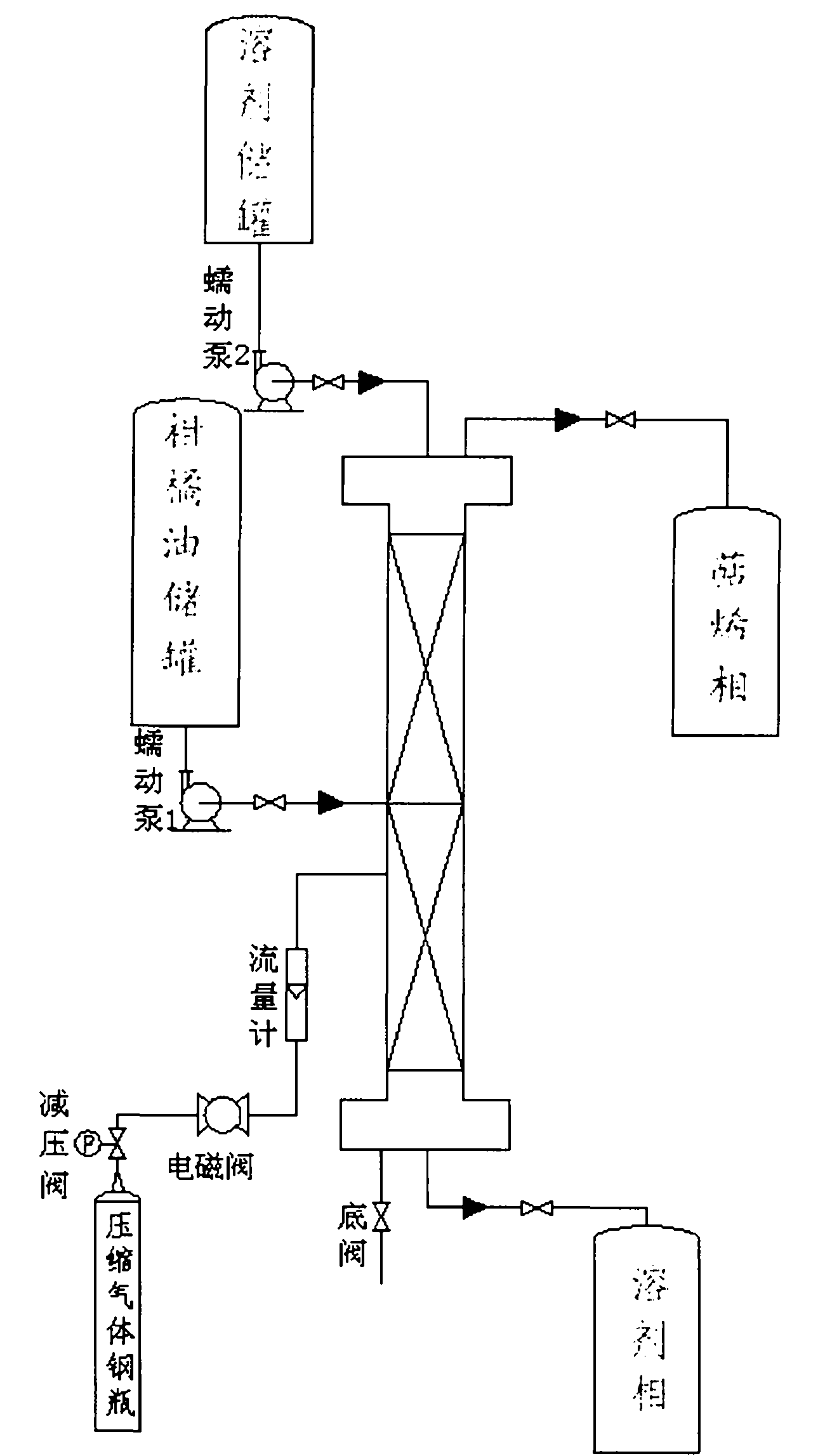

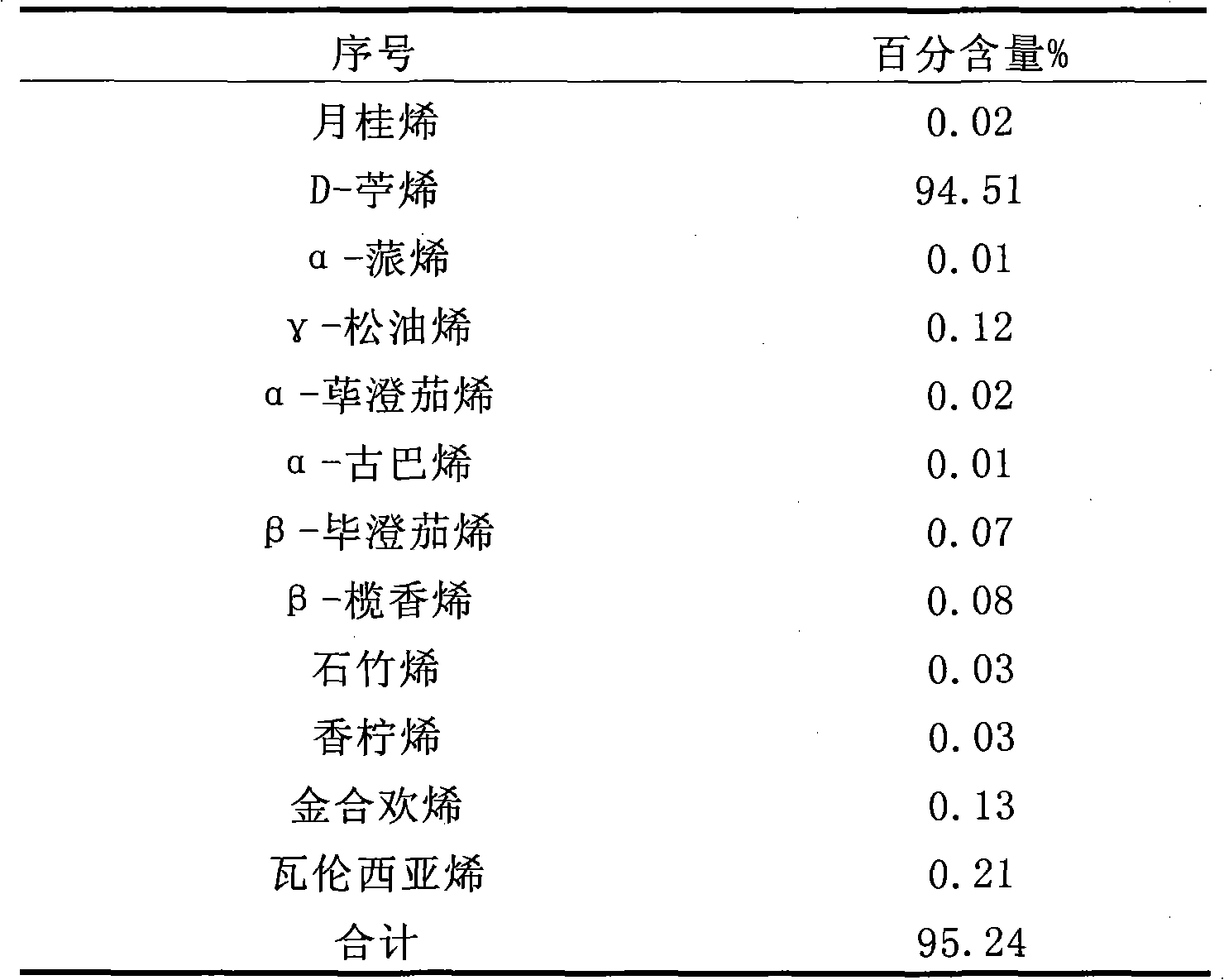

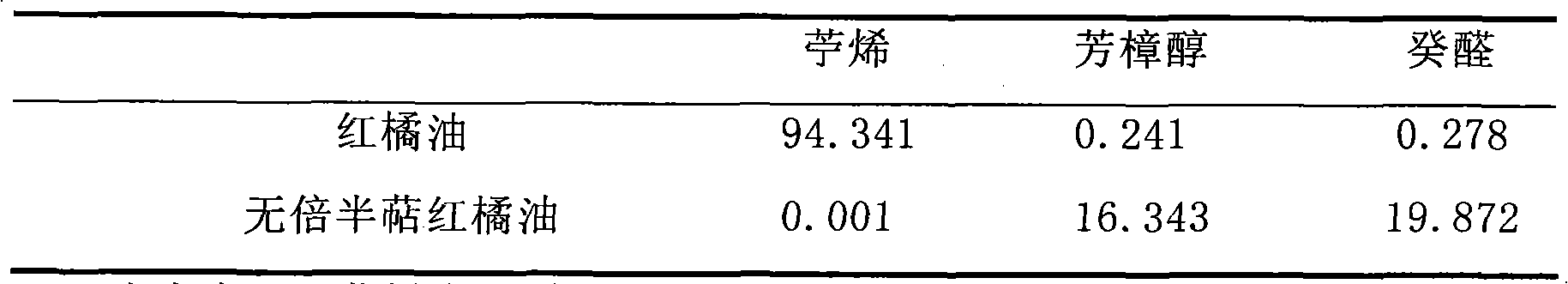

[0020] see figure 1 , select the column height of the pulse extraction column to be 1m-3m, and the column height-to-diameter ratio is 10-50. In this embodiment, the column diameter is 50mm and the column height is 1100mm. The column body is made of glass with a thickness of 2.5mm, and the column is filled with stainless steel CY700 type filler. The binary solvent selects ethanol and water, 70% ethanol-water solution, totally 2500g, tangerine oil 500g. The extraction is carried out under normal pressure at 1 to 1.2 atmospheres, and at room temperature between 15°C and 25°C. The pulse generator is composed of an air compressor, compressed air, nitrogen or carbon dioxide cylinder, and a solenoid valve. This embodiment uses a pulse generator composed of a compressed air cylinder and a solenoid valve. The vibration frequency is controlled by the solenoid valve, and the pulse amplitude is controlled by the gas pressure. , The pulse amplitude is 12.5 ~ 25mm. The debugging process ...

Embodiment 2

[0031] Same as Example 1, the difference is that 500 g of sweet orange oil is placed in the pulse extraction column of Example 1, methanol and water are selected as the binary solvent, and 65% methanol-water solution is made, and about 10 g of sweet orange oil is separated by extraction and salting out. Sesquiterpene-free sweet orange oil. Wherein the total aldehyde content (calculated as decanal) is 30.12%.

[0032] Methanol was not detected by chemical method, and the aroma of sesquiterpene-free sweet orange oil was found to have a very strong sweet orange characteristic aroma, and the fragrance retention time was 4 times longer than that of sweet orange essential oil, up to 20 hours. The aroma is transparent, realistic and fruity.

Embodiment 3

[0034] Same as Example 1, the difference is that 500g of lime oil is placed in the pulse extraction column of Example 1, and 75% ethanol-water solution is selected for binary statistics. In order to ensure complete separation of the two phases, the density of ethanol-water solution is controlled to be greater than that of the terpene phase. If 0.03g / cm3 is insufficient, add some sodium chloride to the solution to increase the density. Finally, about 35g of sesquiterpene-free white lemon oil is obtained, which has a strong white lemon aroma and cola-like aroma, and the fragrance lasts for as long as 48 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| refraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com